What is Precipitation Hardening? A Comprehensive Guide

Aug 07,2024

Aug 07,2024

Precipitation hardening is done on materials like aluminum, stainless steel, and titanium alloy. Precipitation hardening heat treatment enhances the yield strength of the malleable materials. The material should provide a good strength-to-weight ratio for automotive, medical devices, and aerospace applications. Ph techniques and precision machining are the characteristics of Tuofa CNC machining. Tuofa offers specialized machining done by expert workers.

Understanding the Fundamentals of Precipitation Hardening

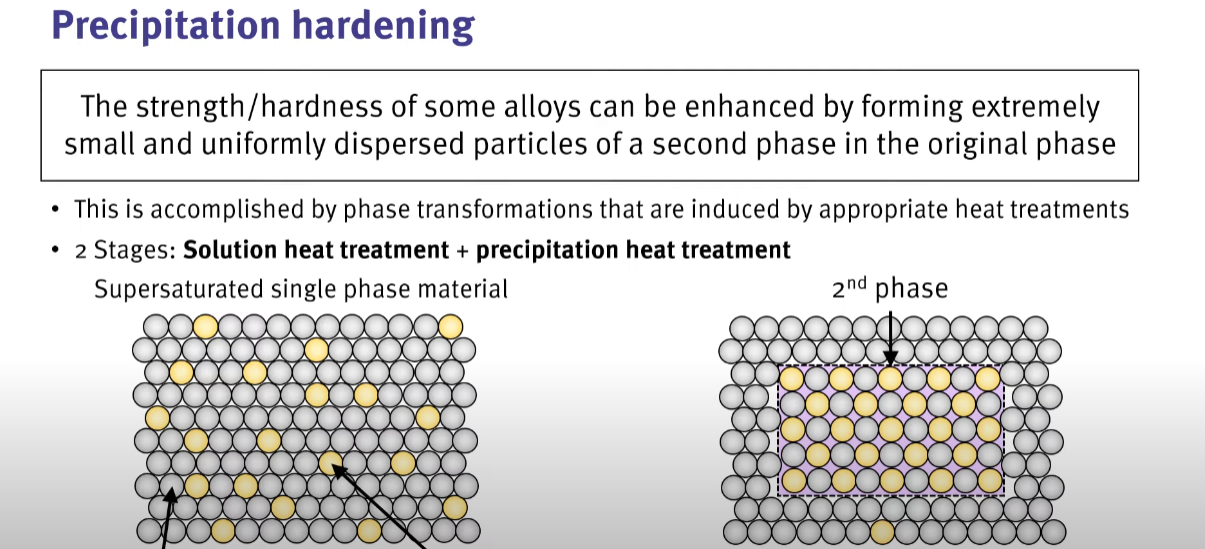

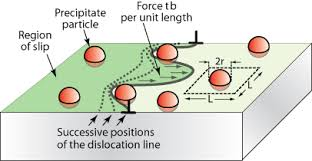

Precipitation hardening chemistry involves the fine precipitation formation of the grain structure. The yield strength and hardness of the material are enhanced due to precipitation hardening. Dislocation movement is hindered by the fine particles in the matrix providing strength to the material.

Precipitation Hardening example

Precipitation hardening heat treatment is used to produce alloys for aerospace applications. For example, aluminum alloy 7075 is used in the structure of aircraft. 7075 aluminum alloy contains magnesium, zinc, and silicon alloy elements. This alloy is precipitation-hardened to achieve the desired durability and strength for structural application.

Basic Principles

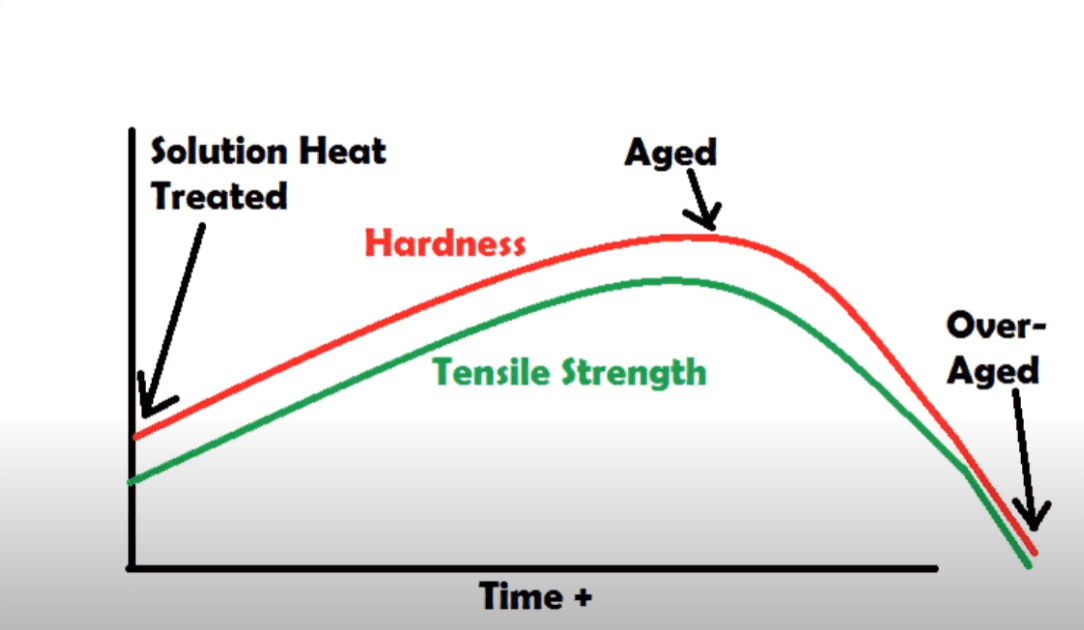

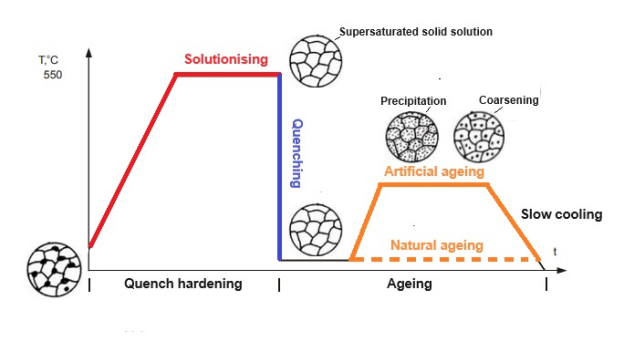

Controlled heating and cooling processes are done in the precipitation hardening heat treatment. These heating and cooling processes will allow the material to enhance strength and hardness. Three basic steps of precipitate hardening heat treatment are solution heat treatment, quenching, and aging. First, the material is heated at a high temperature to dissolve the alloying element making a homogenous solution. This solution is rapidly cooled in water and then reheated at a low temperature so that the alloying element would precipitate out making a supersaturated solution.

Synonym for Precipitation Hardening

Age hardening is the basic synonym for precipitate hardening which reflects aging at elevated temperature and room temperature. Another synonym is particle hardening which refers to the formation of particles in the matrix during Ph hardening.

Key Terminology

Some key terminologies used in precipitation hardening are given below.

- Solid Solution: The homogeneous solution formed after solution heat treatment. Alloying elements are dissolved in the matrix.

- Supersaturation: The alloying element is precipitated out in solution. This solution is called a supersaturated solution.

- Nucleation: The second phase of precipitation is formed within a supersaturation sold solution after the initial stage of small nuclei is formed.

- Growth: The nuclei are grown, and the precipitate size is increased.

Chemistry of Precipitation Hardening

Precipitation hardening chemistry involves the formation of fine particles of equal size within the matrix of alloy. The distribution of the fine particles should be uniform for better strength and hardening.

Microstructural Analysis of Precipitation Hardened Alloys

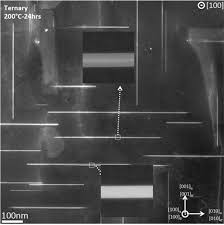

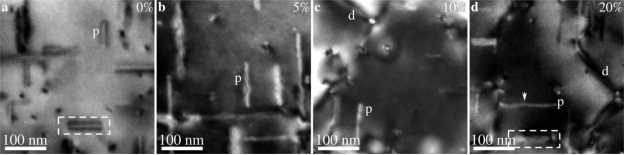

The particle size and distribution throughout the matrix are very crucial in determining the strength and hardness of the alloy. TEM and SEM analysis is done on the alloy after every step to notice the effect of temperature and time on the particle size and distribution. TEM and SEM images also allow the analysis of the morphology of particles.

Precipitation is seen in the TEM image after PH hardening.

Different Types of Precipitates

Precipitation different types and their effect on the properties of material are given below.

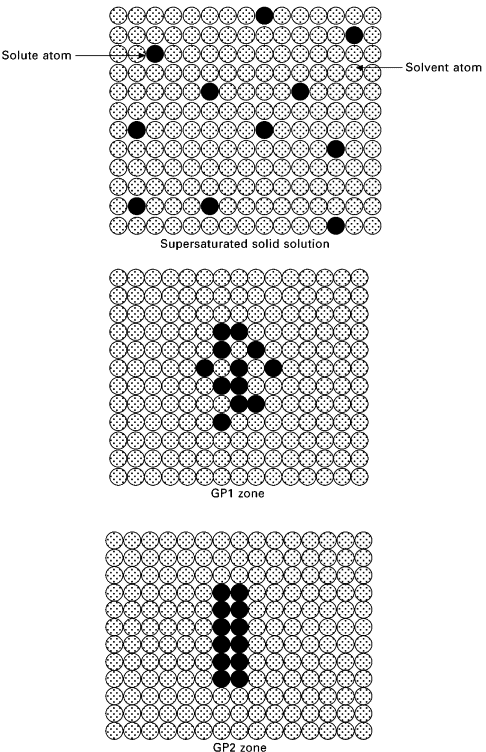

- Guinier-Preston (GP) Zones

- Theta Prime (θ')

- Theta Double Prime (θ'')

- Eta (η) Phase

Precipitation phases

GP Zones (Guinier-Preston Zones)

Coherent clusters of sine solute atoms are formed. This has improved hardness and strength without affecting ductility.

Schematics show the transformation from a supersaturated solid solution to GP1 zone to GP2 zone during aging.

θ' (Theta Prime) Precipitates

Rod-like precipitation and semi-coherent precipitation hardening chemistry are found on AL-Cu alloys. Impend dislocation movement and provide substantial hardness and strength.

SEM image of AL-CU alloy showing θ' (Theta Prime) Precipitates.

β'' (Beta Double Prime) Precipitates

Coherent and needle-like precipitates hardening chemistry are found inAl-Mg-Si (6xxx series) alloys. With good hardness, strength, and ductility it also provides good corrosion resistance.

TEM image of β'' (Beta Double Prime) Precipitates.

η' (Eta Prime) Precipitates

Coherent and plate-like precipitates hardening chemistry is formed normally found on Al-Zn-Mg-Cu (7xxx series) alloys. Provide high hardness and strength to the alloy that can be used in aerospace structures.

TEM image of η' (Eta Prime) Precipitates of 7075-LCu.

S' (S Prime) Precipitates

Semi-coherent and plate-like precipitates are formed mainly in Al-Cu-Mg (2xxx series) alloys. Provide high hardness and strength for load-bearing applications.

The Role of Dislocations in Precipitation Hardening

The dislocation movement is impeded by precipitation and enhances the material's strength and hardness. Defects and dislocation movement within the crystal structure play important roles in explaining the mechanical behavior of the material. The interaction of precipitate and dislocation explains the fundamentals of the strengthening process.

Advantages and Disadvantages of Precipitation Hardening

The advantages and disadvantages of precipitation hardening are given below.

Advantages

- Improved hardness and strength.

- Wear resistance is improved.

- High strength-to-weight ratio.

- Improved fatigue resistance.

- Extended lifespan.

Disadvantages

- The heat treatment process is complex and requires a proper heating and cooling process.

- Time consuming process.

- Over-age sensitive.

- Improving hardness to compromise ductility.

- Corrosion and stress corrosion cracking sensitive.

Factors Affecting Precipitation Hardening

| Factor | Description | Effect on Material Properties |

|---|---|---|

| Alloy Composition | The types and amounts of alloying elements present in the base metal. |

|

| Alloying Element Chemistry | The chemical interactions between the alloying elements and the base metal. |

|

| Phase Stability | The stability of the precipitated phases and the absence of undesirable phases. |

|

| Heat Treatment Parameters | The temperature and time of solution heat treatment and aging. |

|

| Precipitate Characteristics | The size, morphology (shape), and distribution of the precipitates within the matrix. |

|

What are the Three Steps in Precipitation Hardening?

The second phase of hardening heat treatment is done in 3 steps: solution heat treatment, quenching, and aging. All these three steps are crucial in enhancing the mechanical properties of the material. Balancing between ductility and hardness is very important.

Solution Treatment

The metal alloy is heated above the solidus line. This high-temperature heating would dissolve all alloying elements in a solid solution. The homogenous distribution of elements throughout the metal matrix.

Quenching

Quenching is the second step where the material is rapidly quenched in water. This step is crucial for aging. These steps allow material to make supersaturated metaphase. The precipitates are trapped in a matrix of material.

Aging

Aging is done to allow the precipitate to grow into a metal matrix. These precipitates enhance the strength and hardness of the material. There are two types of aging natural aging and artificial aging. For aluminum alloy aging temperature ranges from 120°C to 190°C.

Schematics explain the full process of precipitation hardening.

YouTube video explaining precipitation hardening mechanism.

https://www.youtube.com/watch?v=fsTUDSrXt84&pp=ygUYcHJlY2lwaXRhdGlvbiBoYXJkZW5pbmcg

Natural Aging vs. Artificial Aging

Natural aging is done at room temperature. It takes longer time even up to weeks to months. Artificial aging is done typically at elevated temperatures of 120°C to 190°C. Artificial aging takes less time compared to natural aging ranging from a few hours to days.

Metals Ideal for Precipitation Hardening

Precipitation hardening heat treatment is done on soft and ductile materials to enhance their hardness and strength. Particle hardness is the process of forming precipitates inside the material matrix. These precipitates interact with dislocation and strengthen the material. Some materials that are precipitation-hardened are given below.

Aluminum Alloys

Aluminum is lightweight and can be used for aircraft and automotive industry. Aluminum is ductile and soft to enhance its hardness and strength for advanced applications, it is particle-hardened. Aluminum following series are particle hardened.

- 2xxx Series also called as Aluminum-Copper Alloys.

- 6xxx Series also called as Aluminum-Magnesium-Silicon Alloys.

- 7xxx Series also called as Aluminum-Zinc Alloys.

Nickel-Based Superalloys (Inconel 718)

This alloy contains chromium and nickel primarily but also contains niobium, titanium, and molybdenum in it. When Inconel is particle hardened it forms and gamma-double prime (γ’) precipitates form and gamma-prime (γ') when aged. This provides material creep resistance and high-temperature strength.

Titanium Alloys (Ti-6Al-4V)

Is the most widely used alloy of titanium containing 4% vanadium and 6% aluminum. After aging beta phase matrix is formed in which fine alpha (α) phase precipitates are formed. These phases enhance the strength and toughness of the alloy.

PH Stainless Steels (17-4 PH, 15-5 PH)

17-4 PH: Contain nickel, copper, chromium, and niobium in it. The precipitates formed are copper-rich fine Particles. These enhance the hardness and strength of the alloy.

15-5 PH: Overall composition is the same as 17-4 PH stainless steel but has slightly different amounts of each element. This composition is designed to enhance the toughness of the alloy. Copper-rich precipitates are formed to improve mechanical properties during aging.

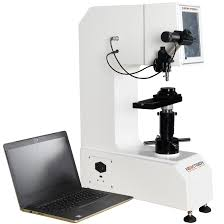

Hardness Testing Methods

Hardness testing can be done from 3 equipment described below.

Rockwell Hardness Testing

It is the measure of a large load indentation depth penetration concerning preload penetration. It has scales of HRA, HRB, and HRC.

Rockwell hardness equipment.

Vicker hardness testing

The size of the indentation is measured to calculate hardness. Diamond pyramid indenter is used for this purpose.HV is the Vickers hardness number.

Vicker hardness equipment.

Brinell Hardness

A hard carbide or steel ball under a special load is used to press into the material. The hardness is calculated by measuring the diameter of the indentation. HBW is used for tungsten Carbide balls. HBS is used for steel balls.

Brinell hardness equipment.

Applications of Precipitation Hardening Across Industries

Precipitation hardening heat treatment is used across different industries to tune the mechanical properties of alloys.

Aerospace Industry: 7075 and 2025 aluminum alloy PH is used in making different aerospace components. Wings, fuselage frames, and landing gear parts are formed by these Particle hardened alloys. Inconel 718 is used in automotive and aerospace engine parts.

Automotive Industry: 6xxx and 7xxx series aluminum alloys are used in high-performance engines. Ti-6Al-4V is used in cars and vehicles' structural parts. The exhaust system is manufactured from 17-4 PH stainless steel.

Medical Industry: Ti-6Al-4V titanium alloy is used in implants and prosthetics due to its biocompatibility. 17-4 PH stainless steel and 15-5 PH stainless steel are used in surgical instruments.

Oil and Gas Industry: Nickel-based super alloy precipitation hardened are used in drilling equipment, fittings, and valves. 17-4 PH stainless steel is used in manufacturing pressure vessels and pipes.

Marine Industry: 5xxx and 6xxx series aluminum alloys are used in making superstructures and ship hulls. Nickel-based precipitation-hardened alloys are used to make shafts and propellers.

Electronics Industry: Copper alloys which are particle-hardened are used to manufacture electrical contacts and connectors. Aluminum alloys are used to make heat sinks.

CNC Machining and Precipitation Hardening: A Powerful Combination

Tuofa CNC machining provides precipitation-hardening heat treatment that results in durable and high-precision components. CNC machining of Toufa provides excellent surface finish, consistent production, and accuracy. Precipitation hardening heat treatment increases the wear resistance and strength of the material. Tuofa provides the best service with highly equipped CNC machining for precipitation-hardened metals. For more details, you can see their website given below.

Comparison with Other Strengthening Mechanisms

There are many strengthening mechanisms used in industry to improve alloy mechanical properties. Strengthening mechanisms include precipitation hardening, grain refinement, and solid solution hardening. The difference between different strengthening mechanisms and precipitation hardening is discussed below.

Precipitation Hardening vs. Work Hardening

Work hardening is the process in which material is plastically deformed. Dislocations are created within the material. These accumulated dislocations hinder each other's movement, hence strengthening the material. While second phase hardening is the process in which precipitates are formed that interact with dislocation and strengthen the metal.

Precipitation Hardening vs. Grain Refinement

Grain refinement is the process in which the grain size is decreased. Decreasing grain size causes more grain boundaries. These grain boundaries restrict the movement of dislocations and strengthen the metal. Second phase hardness on the other hand is the heat treatment process. This precipitate-hardening chemistry involves the formation of precipitate in the metal matrix that strengthens the material.

Precipitation Hardening vs. Solid Solution Strengthening

Solid solution hardening involves the addition of alloying elements into the metal matrix to improve strength. While precipitation hardening is the 3 steps of heat treatment. Solid solution-strengthening precipitates are added as alloying elements that hinder dislocation movement. Precipitation hardening chemistry is when precipitates are formed by heat treatment.

Chinese Machining Services

Precision Engineering for Innovators

Send drawings to info@tuofa-cncmachining.com

Faster and Cheaper

FAQs

Precipitation Hardening vs. Age Hardening

Both synonyms refer to the heat treatment process involving solution heat treatment, quenching, and aging.

Dispersion Hardening vs. Precipitation Hardening

Dispersion hardening is not a heat treatment like precipitation hardening. It is the process of adding nonmetallic particles into the metal matrix to increase the hardness and strength of the material.

What is the difference between tempering and Precipitation Hardening?

Tempering is done to hardened steel to reduce its brittleness and to improve toughness. It's a reheating process at low temperatures to remove the internal stresses of the material. In this process, precipitates are not formed. On the other hand, precipitate hardening involves three steps, and precipitates are formed to increase hardness.

Which is stronger, precipitation-hardened stainless steel or aluminum?

The tensile strength of the PH stainless steel is 850 MPa to 1,700 MPa while of aluminum is 90 MPa to 690 MPa. So, PH stainless steel is stronger than aluminum.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Damascus Steel vs Stainless Steel: Which is Better?

Damascus Steel vs Stainless Steel: Which is Better?