5083 Aluminum: Properties, Applications, and Machining Techniques

May 23,2024

May 23,2024

Aluminum alloys are good low temperature materials. They have high strength in subzero temperatures. corrosion resistance, fracture toughness and electrical conductivity are also excellent in these materials. However, when they are exposed to elevated temperatures, their strength reduces. This high temperature range is from 200-250℃. 5000 series aluminum alloys are very commonly used grades almost in all types of industries. 5083 Aluminum among them is known for its exceptional corrosion resistance properties. This article thoroughly discusses the properties, applications and other important aspects of 5083 Aluminum.

Overview of 5083 Aluminum Alloy

5083 Aluminum is famous for its harsh environments’ corrosion resistant nature. It has exceptionally high resistance to seawater and chemical environments and stress corrosion cracking. Strength is also great in alloy 5083 which retains easily after welding. It has moderate thermal properties. However, the heat treatments do not have much effect on this material. it is normally not recommended to use above 65℃.

Advantages and Disadvantages of 5083 Aluminum

Advantages

- EN-AW5083 alloy is very suitable for applications of high strength to weight ratio material.

- Corrosion resistance to salty water and harsh chemicals is excellent.

- It is very suitable for stress corrosion cracking resistance applications.

- The response to automated and manual welding is very good in EN-AW5083.

- It is ductile and malleable suitable for any machining operations.

- Superior workability and ductility is useful in the long life of the product.

- Anodizing gives the best results on 5083 aluminum

Disadvantages

- 5083 Aluminum has high performance which increases its cost and makes it one of the expensive materials among 5000 series alloys.

- This alloy is not heat treatable and has moderate thermal properties. Heat treatment does not leave any significant impact on its properties.

- This alloy is not suitable for temperature above 65℃.

What is equivalent to 5083 Aluminum?

These alloys are equivalent to 5083 Aluminum.

|

AMS 4057 |

ASTM B210 |

MIL A-45225 |

AMS 4058 |

|

ASTM B241 |

ASTM B221 |

MIL A-46027 |

AMS 4057 |

|

ASTM B548 |

ASTM B361 |

MIL A-46083 |

QQ A250/6 |

|

ASTM B209 |

ASTM B547 |

MIL G-S-24149/2 |

QQ A-200/4 |

Corrosion Resistance

En-AW5083 has very high corrosion resistance. It is commonly used alloy in marine applications. The presence of Cr, Mg and Mn make it very resistant to saltwater. Its corrosion resistance is also high at sub-zero or cryogenic temperatures. This makes it more demanding in automotive industries and a popular grade in aerospace industries.

Chemical Composition and Alloy Additives

5083 aluminum is an aluminum magnesium alloy. Other elements are present in percentage mentioned below:

|

elements |

Percentage |

|

Magnesium |

4-4.5% |

|

Manganese |

1% |

|

Iron |

0.4% |

|

Zinc |

0.25% |

|

silicon |

0.4% |

|

copper |

0.1% |

|

Titanium |

0.15% |

|

Aluminum |

Balance |

Mechanical Properties

|

Mechanical properties |

values |

|

Yield strength |

145MPa |

|

Tensile strength |

300MPa |

|

Elongation |

23% |

|

Shear strength |

175MPa |

|

Hardness |

75HV |

Physical Properties

|

Physical properties |

values |

|

Density |

2.65Kg/m3 |

|

Melting point |

570℃ |

|

Thermal expansion |

25x10-6/K |

|

Elastic modulus |

72GPa |

|

Thermal conductivity |

121W/m.K |

|

Electrical resistivity |

0.058 x10-6Ω.m |

What is 5083 Aluminum Used For?

5083 aluminum is a non-heat treatable alloy that is primarily used in the automotive industry. It has good corrosion resistance and weldability, making it ideal for use in applications where these properties are important. Some common uses of 5083 aluminum include:

Marine and Aerospace Applications

5083 Aluminum specially tempered 5083H116 and 5083h32 are commonly used materials in marine industry. They have the highest corrosion resistance to seawater, salts and other chemicals. Hulls are mostly constructed from these alloys. Other applications include offshore drilling rigs and components for yachts and cruise ships.

5083h116 and 5083h32 are used in making aircraft parts like wing skins. Bulkheads and fuselage panel. Their high strength to weight ratio and corrosion resistance makes it is very suitable for making structural parts for aircraft and space shuttles.

Aluminum 5083 flange

Transportation and Infrastructure

Aluminum 5083 can survive harsh weather and winds and has high corrosion resistance. It is used to make structures like roofings, wall cladding, water tanks in construction industries. high stress corrosion cracking resistance and good performance in cryogenic temperature makes it useful for making transportation vehicle parts.

Manufacturing Processes and Product Forms

The manufacturing process of aluminum 5083 products like sheets, bars and ingots, plates and tubes are as:

- Smelting: aluminum ingot with other essential metals is melted in furnace.

- Casting: molten metal is poured into the mold and cool down.

- Heating: to gain require shape, it is heated to a certain temperature

- Rolling: ingots are gone through rolling mill and their thickness is reduced to get desired thickness.

- Straightening: aluminum plates are straightened to reduce deformation.

- Finishing: process is finished by removing oil stains and defects from the surface

Machining and working with 5083 Aluminum

Machining Techniques

5083 alloy has very good machinability. It does not show any issue while machining. Conventional machining methods give the best results with 5083 aluminum. For best stock removal, high speed, feed rate and light cuts with high helix cutter are recommended. But it’s better to do experimentation first with very batch.

Tools and Techniques

One of the recommended techniques to use is to use coolant on tools. It minimizes the galling and fusion when chips are sticky. For threaded holes, it is better to use tapping rather than thread milling to get good results. High helix cutter is recommended to use.

Welding and Assembly

Aluminum 5083, 5083h116 and 5083h32 show no issue in welding. Recommended filler for 5083 is 5183. Other fillers like 5356 and 5556 can also be used.

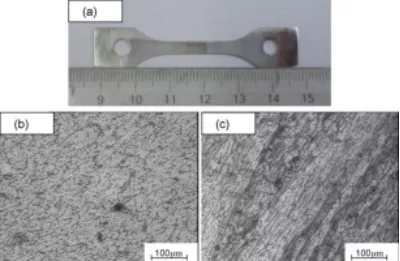

Microstructure of aluminum 5083 weldments by TAW

Image copyright; https://www.sciencedirect.com/science/article/abs/pii/S0921509312005175

Finishing Techniques

Anodizing is the best finishing technique for 5083h116 and 5083h32. It gives good protection to surface. The anodizing can be use are:

- Natural sulphuric anodizing.

- Colour sulphuric anodizing.

- Natural hard anodizing.

- Colour hard anodizing.

Comparison with Other Aluminum Alloys

5083 vs 6061Alloys

6061 has easier processing than 5083. But 5083 has higher strength and fracture toughness and has higher corrosion resistance. 6061 also has good corrosion properties but it reduces when exposed to air.

5083 vs 7075 Alloys

7075 alloy is best for high strength and fracture toughness applications. 5083 is good for higher corrosion protection for harsh environments.

5086 VS 5083 aluminum?

5083 is stronger than 5086. 5086 has good welding properties and has slightly higher corrosion resistance because of slightly different composition. But both are aluminum magnesium alloys.

Addressing Specific Needs with 5083

Thermal properties of 5083 aluminum are moderate. Special attention must be given when selecting service temperature. It is not a heat treatable alloy. And it is not recommended to use above ℃.

Technical Challenges and Innovations

Overcoming Challenges in Machining

5083 has good machinability and has no special machining issues. But to overcome the normal machining challenges, following practice must be done:

- Rigid tools and toolholder must be applied.

- Tools edges must be grounded to reduce builup

- sharp cutting edges

- chips direction must be away from workpiece to prevent tool damage.

Advanced Fabrication Techniques

Friction stir processing is an advanced methos used for 5083h116 and 5083h32. It alters the metal properties by intense localized plastic deformation. A non-consumable tool is inserted in the workpiece that introduces deformation. It revolves in stir motion and pushes laterally through the workpiece.

Conclusion

5083 aluminum has high corrosion resistance in harsh environments. This alloy has moderate thermal properties and is not heat treatable. Strength, fracture toughness and stress corrosion cracking resistance is high in 5083h116 and 5083h32. It is mostly used in marine applications.

Want to know how Tuofa can help you create value in your aluminum 5083 CNC machining project?

Contact Tuofa. As a CNC machining factory established in China in 2006, we have particularly rich experience in manufacturing small batches of high-quality 5083 parts. We believe that we are the choice of the world's top 500 companies.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

305 Stainless Steel: Properties, Applications, and Manufacturing Insights

305 Stainless Steel: Properties, Applications, and Manufacturing Insights