What is Stainless Steel? Properties, Types, and Applications

Apr 05,2024

Apr 05,2024

In this article, you will get in-depth knowledge of the properties, types, and applications of stainless steel. Stainless steel designated as a sus material by the Japanese is an alloy of steel specially designed for corrosion resistance. Although stainless steel resistance to corrosion is the most desired characteristic but along with corrosion resistance it has good heat resistance, excellent strength, hygiene properties and durability. Do you know that sus material production according to provided data at the International stainless-steel forum has reached up to 52 million metric tons globally in 2020? This vast use of stainless steel is due to superior SUS stainless steel characteristics making it desirable in a vast range of applications.

What is Stainless Steel?

Iron alloy containing 10.5% chromium and 0.2-2.11% nickel is known as stainless steel which makes oxide passivation layer when exposed to air. This oxide layer protects internal material form further oxidation. This passivation layer is the main reason stainless steels have high corrosion resistance.

Stainless Steel History

Who invented stainless steel?

English metallurgist, Harry Brearley invented stainless steel. In 1913 in England, Sheffield produced the first batch of stainless steel with 0.24% carbon and 12.8% chromium content.

What is stainless steel made of

Stainless steel is an alloy of iron and chromium mainly which is almost 10.5% chromium content with some amount of nickel and additional elements like molybdenum, titanium, niobium, and magnesium.

What element is steel?

|

Steel Grade |

Carbon (C) |

Chromium (Cr) |

Nickel (Ni) |

Manganese (Mn) |

Molybdenum (Mo) |

Vanadium (V) |

Phosphorus (P) |

Sulfur (S) |

|

ASTM A36 (Carbon Steel) |

0.25% - 0.29% |

- |

- |

0.60% - 0.90% |

- |

- |

0.04% (max) |

0.05% (max) |

|

AISI D2 (Tool Steel) |

1.40% - 1.60% |

11.00% - 13.00% |

- |

- |

0.70% - 1.20% |

0.70% (max) |

- |

- |

|

AISI 304 (Stainless Steel) |

0.08% (max) |

18.00% - 20.00% |

8.00% - 10.50% |

2.00% (max) |

- |

- |

- |

- |

|

AISI 316 (Stainless Steel) |

0.08% (max) |

16.00% - 18.00% |

10.00% - 14.00% |

2.00% (max) |

2.00% - 3.00% |

- |

- |

- |

|

AISI M2 (High-Speed Steel) |

0.78% - 0.88% |

3.75% - 4.50% |

- |

- |

4.50% - 5.50% |

1.75% - 2.20% |

- |

Table showing different grades of steel with elemental composition.

Why is it called stainless steel?

The shines and corrosion resistance properties of Resistance stainless steel dictates its name “stainless’. The oxide layer formed on the surface of stainless-steel acts as a protective barrier preventing further oxidation of internal steel making steel “stainless”. Japanese also called resistance stainless steel as SUS material.

YouTube video showing what is stainless steel and how it is made. https://www.youtube.com/watch?v=JAfSVE-NFNQ&pp=ygURc3RhaW4gbGVzcyBzdGVlbCA%3D

What is stainless steel classified as

Steel alloy is the main class of stainless steel. Stainless steel is also known as corrosion resistant alloy because its show excellent corrosion resistance property due to high chromium content.

Stainless steel symbol

"SS" Is the symbol used to represent stainless steel. Each grade is specified by its unique designation like 304 stainless steel is designated as 304 stainless steels.

![]()

Figure showing logo used for stainless steel equipment.

Is Stainless Steel a Solution?

Stainless steel is not considered a solution because the solution has a homogeneous mixture while stainless steel has a solid solution in which different elements are distributed uniformly throughout the crystalline structure which is considered as alloy.

Understanding the Properties of Stainless Steel

|

Property |

Description |

|

Corrosion Resistance |

Stainless steel produces a passive oxide layer which provides corrosion resistance to stainless steel. |

|

High-Temperature Resistance |

Can maintain its mechanical properties at elevated temperatures. |

|

Strength and Durability |

|

|

Hygienic Properties |

|

|

Aesthetic Appeal |

|

|

Ease of Fabrication |

Malleable and ductile |

|

Recyclability |

Easily remelted and reused making it sustainable. |

Table describing the different properties of stainless steel.

Composition and Basic Properties

Stainless steel is alloy of iron and chromium with 10.5% chromium content and some content of nickel which is 0.2-2.11%. It may contain other elements like nickel, molybdenum, titanium, niobium, and manganese.

Some stainless-steel properties are given below.

- Corrosion Resistance

- High-Temperature Resistance

- Strength and Durability

- Hygienic Properties

- Aesthetic Appeal

- Ease of Fabrication

- Recyclability

- Show Magnetic properties

- Good creep strength.

1. Chromium Content and Corrosion Resistance

Stainless steel is best known for its corrosion resistance which is due to the presence of high amount of chromium content compared to other steel alloys. Chromium forms a passivation layer above the surface of stainless steel which protects the underlying steel from harsh environments.

2. Nickel, Molybdenum, and Other Alloying Elements

|

Alloying Element |

Effects |

|

Carbon (C) |

|

|

Chromium (Cr) |

|

|

Nickel (Ni) |

|

|

Manganese (Mn) |

|

|

Molybdenum (Mo) |

Improves corrosion resistance, especially in acidic environments. |

|

Vanadium (V) |

|

|

Silicon (Si) |

|

|

Copper (Cu) |

|

|

Aluminum (Al) |

|

|

Titanium (Ti) |

|

|

Nitrogen (N) |

Refines grain structure and increases hardness. |

|

Sulfur (S) |

Enhances machinability but surprisingly also reduces toughness and ductility if added excessively. |

|

Phosphorus (P) |

|

Table showing the effect of different alloying elements in stainless steel making.

YouTube video showing stainless steel grade testing liquid. https://www.youtube.com/watch?v=76xO32sp8w8&pp=ygUYdGVzdGluZyBvZiBzdGFpbmxlcyBzdGVl

Mechanical Properties

Hardness, Ductility, Formability, and tensile strength

|

Property |

Hardness (HRC) |

Ductility and Formability |

Tensile Strength (MPa) |

|

Stainless Steel |

40-55 |

High |

520-860 |

The table showing the Normal trend in stainless steel hardness, Ductility, Formability, and tensile strength can be seen above.

YouTube video showing tensile testing of stainless steel. https://www.youtube.com/watch?v=67fSwIjYJ-E&pp=ygUYdGVzdGluZyBvZiBzdGFpbmxlcyBzdGVl

How strong is stainless steel?

SUS material strength varies based on its grade, composition, and heat treatments. Tensile strengths of up to 200 ksi (1378 MPa) or more are typically seen in resistant stainless steel. Not all stainless steel has this strength common stainless steel fasteners have a tensile strength of approximately 75,000 lb/in^2. Common stainless-steel fasteners are SAE grade 2 steel which is weaker than high-tech application stainless steel of grade 5.

Physical Properties

|

Grade |

Density (g/cm³) |

Thermal Conductivity (W/m·K) |

Magnetic Properties |

Electrical Conductivity (%IACS) |

Melting Temperature (°C) |

|

304 |

7.93 |

16.2 |

Non-magnetic |

2.5 |

1400-1450 |

|

316 |

7.98 |

16.3 |

Non-magnetic |

2.5 |

1375-1400 |

|

430 |

7.7 |

23 |

Magnetic |

1.1 |

1425-1510 |

|

201 |

7.81 |

16.2 |

Non-magnetic |

2.5 |

1400-1450 |

8 Benefits of Stainless Steel

- Corrosion Resistance

- Heat and Fire Resistance

- Hygiene

- Impact Resistance and Strength

- Aesthetic Appeal

- Sustainability

- High creep strength

- 8.High magnetic properties (ferritic stainless steel)

Special Characteristics of Stainless Steel

1. Alloy Strength and Resistance: presence of high chromium content compared to other steel provides stainless steel high corrosion property. Other additional elements may provide stainless steel properties include high creep strength, heat and fire resistance, hygiene, and impact resistance.

2. Chromium's Role: Chromium content provides excellent corrosion resistance by formation of oxide layer on the surface that act as protection layer to inner material.

3.Components of Stainless Steel CNC Machining: CNC machining is done to produce complex, high-quality, precise finish stainless steel components for high-tech applications.

4. Weldability: weldability is a key consideration in complex component fabrication. Choosing appropriate welding techniques and skilled welders is the key consideration in welding.

5. Standard Finishes: appropriate surface treatments like grinding, polishing, and brushing are essential for an excellent appealing finish.

6. Environmental Sustainability: stainless steel can be reused because it can be remelted that is why also a sustainable material.

Stainless Steel 6 Types

1. Martensitic Stainless Steel

High strength, magnetic properties and hardness is the martensitic stainless-steel characteristics.The martensite stainless steel is produced by heat treatment including high-temperature heating of stainless steel and then rapid cooling. This heat treatment converts stainless steel microstructure into martensite. Martensite is a hard crystalline structure. This martensitic stainless steel is used in applications where strength is also the main required property with corrosion resistance.

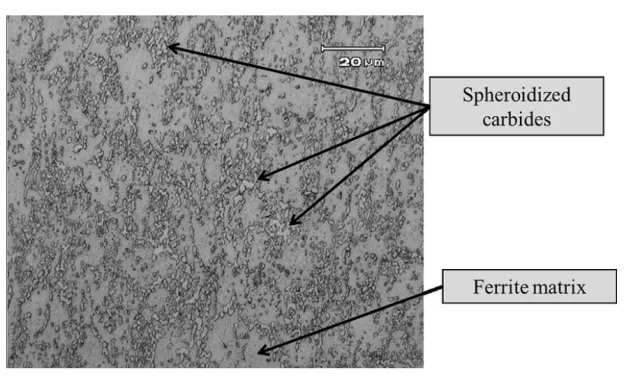

Figure showing martensitic stainless steel microstructure.

1. Cutlery

2. Industrial Equipment

3. Automotive Components

4. Aerospace

5. Surgical Instruments

Figure showing martensitic stainless-steel knife.

2. Ferritic Stainless Steel

|

Feature |

Description. |

|

Corrosion Resistance |

In mild corrosive environments provides good corrosion resistance. |

|

Magnetic Properties |

Good magnetic properties |

|

Heat Resistance |

Moderate heat resistance |

|

Formability |

Easily fabricated and formed. |

|

Cost |

Expensive compared to austenitic stainless steel |

Figure showing ferritic stainless steel kitchen equipment.

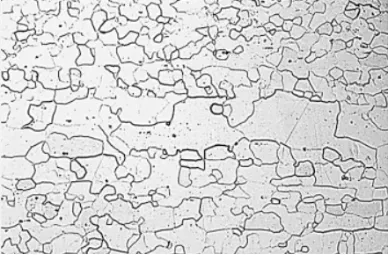

Figure showing typical microstructure of ferritic stainless steel.

400 Series

|

Feature |

Description |

|

Chromium Content |

11% to 27% chromium |

|

Corrosion Resistance |

good resistance to corrosion in moderate environments |

|

Magnetic Properties |

Goof magmatic properties |

|

Strength and Hardness |

|

|

Heat Resistance |

moderate heat resistance |

|

Applications |

industrial equipment, automotive, construction, appliances, cutlery, and aerospace components. |

Table showing features of 400 series of stainless steel.

Examining the properties and uses of this chromium-rich, corrosion-resistant steel

|

Stainless Steel Grades |

Properties |

Applications |

|

304 (UNS S30400) 316 (UNS S31600) 321 (UNS S32100) 347 (UNS S34700) 410 (UNS S41000) 430 (UNS S43000) |

High Chromium Content Excellent Corrosion Resistance Strength and Toughness Heat Resistance |

Marine applications Kitchen Appliances Construction Automotive industry Medical devices Industrial equipment |

Table showing properties and applications of chromium-rich corrosion-resistant steel.

Marine applications

Kitchen Appliances Construction Automotive industry Medical devices Industrial equipment Table showing properties and applications of chromium-rich corrosion-resistant steel.

3. Austenitic Stainless Steel

Austenitic stainless steel has composition of around 18% chromium content and 8% nickel content with additional elements like nitrogen and magnesium.

Properties of Austenitic stainless steel are listed below.

1. Corrosion Resistance

2. Non-magnetic

3. High Ductility and Toughness

Ductility: ranging from 40% to 60%.

Toughness: range from 50 J/cm² to 150 J/cm².

4. Excellent Formability

5. High-Temperature Resistance Ranging from -200°C to 900°C depending upon the specific grade, composition, and heat treatment.

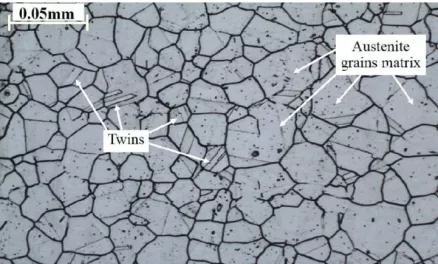

Figure showing microstructure showing austenitic stainless steel.

APPLICATIONS

1. Food Processing: pipes, tanks, and processing machinery.

2. Chemical Processing: vessels, reactors, and piping systems.

3. Medical Devices: surgical instruments and medical devices.

4. Architectural and Structural: handrails, building facades, and decorative elements.

5. Automotive: fuel tanks, automotive exhaust systems, and structural components

Figure showing process vessel of austenitic stainless steel.

200 Series and 300 Series

|

Stainless Steel Series |

Chromium (Cr) Content (%) |

Nickel (Ni) Content (%) |

Other Alloying Elements (%) |

|

200 Series |

around 16-18% |

below 4% |

Varies |

|

300 Series |

around 18-20% |

Higher than 8-10% |

Varies |

Table showing typical composition of 300 and 400 series of stainless steel.

Features Applications 300 and 400 Series of Stainless Steel

|

Stainless Steel Series |

Features |

Applications |

|

300 Series |

Excellent corrosion resistance. High strength. Non-magnetic properties. |

Aerospace Automotive Food processing Chemical processing |

|

400 Series |

Good corrosion resistance High strength Magnetic properties(martensitic) |

Cutlery Industrial equipment Automotive components Aerospace |

4. Duplex Stainless Steel

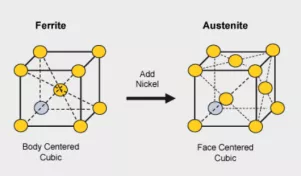

Austenitic plus ferritic structure is found in the duplex stainless steel that’s why have combined properties of both. Duplex stainless steel show good corrosion resistance against crevice and duplex stainless steel and has high strength.Duplex stainless steel atomic structure provides combined features of both austenitic stainless steel atomic structure of face-centered cubic (FCC) crystal structure which is a stable and ductile structure combined with ferritic stainless steel atomic structure which is body-centered cubic (BCC) crystal structure providing strength and toughness to duplex stainless steel [20].

Figure showing the microstructure of Duplex stainless steel.

Application of duplex stainless steel.

- Chemical Processing

- Oil and Gas

- Marine Pulp and Paper

- Structural Engineering

Figure showing duplex stainless steel tube heat exchangers and steel shell side shell.

YouTube video on different types of stainless steel. https://www.youtube.com/watch?v=iPnl6vhDgXA&pp=ygUtZmVycml0aWMgbWFydGVuc2l0aWMgYXVzdGVuaXRpYyBzdGFpbmxlcyBzdGVl

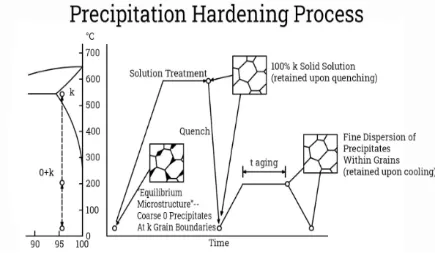

5. Precipitation Hardening Stainless Steel

A specialized stainless-steel alloy known as Precipitation hardening stainless steel is manufactured by heat treatment processes which enhance its strength. This can be done in the following steps.

- Heating the material so that all precipitates dissolve.

- A supersaturated solid solution is formed by rapid cooling.

- Finely dispersed precipitates are formed by aging.

These precipitation-hardening stainless-steel offer 850 MPa tensile strength approximately to almost 1,700 MPa.

Figure showing precipitation hardening process.

YouTube video Precipitation Hardening Stainless Steels guide. https://www.youtube.com/watch?v=lalTnoYKY4k&pp=ygUkcGVydGljaXBhdGlvbiBoYXJkZW5uZyBzdGFpbmxlcyBzdGVl

6. Heat-Resistant Stainless Steel

Certain austenitic and ferritic grades are included in this heat-resistant stainless steel. Heat-resistant stainless steel can retain temperature up to 550° C which is the key property of this steel [25].

Advanced Topics in Stainless Steel

Crystal Structures in stained Steel

Ferrite: ferritic stainless steel atomic structure is body-centered cubic with high magnetic properties. This ferritic stainless steel is used in the fabrication of automotive exhaust systems, washing machines, and countertops.

Austenite: Austenitic stainless steel atomic structure face-centered cubic structure and has non-magnetic properties. Austenitic stainless steel are easier to shape compared to ferritic stainless steel which mean they are less brittle and are easy to weld. Austenitic stainless steel has two major types which are type 304 and 316.

Austenitic stainless steel is used in making kitchen equipment, cutlery, and cookware.

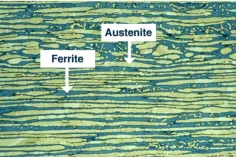

Figure showing conversion of ferritic stainless steel atomic structure to austenitic stainless steel atomic structure.

Martensite: Martensitic stainless steels have a body-centered structure with an axis elongated to form a tetragonal structure.

Understanding Pitting Corrosion

Localized form of corrosion also known as pitting corrosion cause metal surface corrosion by forming holes and pits .This type of corrosion happens when the passivation layer on stainless steel is compromised due to a harsh environment containing halide ions like chloride, extreme PH levels, or environmental pollutants that can break the oxide layer on stainless steel.

The pitting corrosion initiates with non-metallic inclusion or small surface inclusion. The electrochemical reactions in these pits do not alloy self-healing of the passivation layer and lead to pit growth.

Figure showing pitting corrosion in stainless steel.

Beyond Stainless Steel: Copper Alloys

Stainless steel provides good corrosion resistance and mechanical strength compared to copper alloys which provide good formability, conductivity, and aesthetic appeal.

|

Property |

Stainless Steel |

Copper Alloy |

|

Corrosion Resistance |

Excellent corrosion resistance |

Moderate corrosion resistance |

|

Mechanical Properties |

Tensile strength: 500-2000 MPa Yield strength: 200-1800 MPa. Elongation: 40-60%. Hardness (HV): 150-300. |

Tensile strength: 200-600 MPa. Yield strength: 50-400 MPa. Elongation: 10-50%. Hardness (HV): 50-150. |

|

Electrical Conductivity |

low conductivity compared to copper alloys. 1.0 to 1.45 MS/m |

High electrical conductivity 58 to 100% IACS |

|

Thermal Conductivity |

Moderate to high thermal conductivity 14 to 20 W/(m·K) |

High thermal conductivity 90 to 400 W/(m·K) |

|

Cost |

higher cost compared to copper alloys |

lower cost than stainless steel |

|

Density |

Density: 7.75 to 8.05 g/cm³ |

Density: 8.5 to 9.0 g/cm³ |

|

Melting Point |

Melting point: 1400 to 1500°C |

Melting point: 1083°C |

|

Aesthetic Appeal |

sleek appearance, good for contemporary designs |

Traditional aesthetic appearance, used in high-valued decorative applications |

Figure showing a comparison between properties of stainless steel and copper alloy.

Figure showing copper alloy and stainless-steel cookware.

Inox Steel vs Stainless Steel

Both stainless steel and inox steel are the same corrosion-resistant alloy named differently. Inox steel is derived from the French and is mainly used in Europe [31].

Type 304 and type 316 stainless steels: Uniform corrosion takes place

Type 316 has superior corrosion resistance compared to Type 304 due presence of higher molybdenum content which is why it is used in harsh environments like seawater and chemical processors.

Conclusion

Stainless steel is an alloy of iron that provides corrosion resistance and is oxidable, has a chromium content of at least 10.5% and nickel content of at least 0.2-2.11%. Stainless steel is named “stainless” because of its shiny stainless surface finish. Stainless steel is best known for its corrosion resistance, creep strength, high temperature resistance and aesthetic appeal.Stainless steel is mainly known for corrosion resistance that’s why most applications of stainless steel are in harsh environments.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Surgical Steel vs Titanium: Deep into the Properties, Piercings, and Suitability

Surgical Steel vs Titanium: Deep into the Properties, Piercings, and Suitability