Density of Stainless Steel: Essential Knowledge for Engineers

May 16,2024

May 16,2024

Stainless steel is a commonly used construction material globally. It has at least 10.5% chromium combined with other metals which have significant on its structure and material properties. Steel is known for its strength, corrosion resistance and most importantly it is a readily available and affordable alloy. One important feature is its density. This is highly influenced by the type of adding metal and its amount in steel. This article will highlight the main points of density and its effect on steel grade.

Understanding Density

Every material has its own distinct density. This is due to its mass, size, and its atomic arrangement. In a simple way for non-engineers, it is how heavy a material is. Heavy material is denser. And if a material is lighter in size or mass like cotton, then it is less dense. Mass is the amount of a substance in a material. For steels, Computation of density is an important feature in grade selection of steel for any specific application. Chemical composition of stainless steel can affect the density of steel.

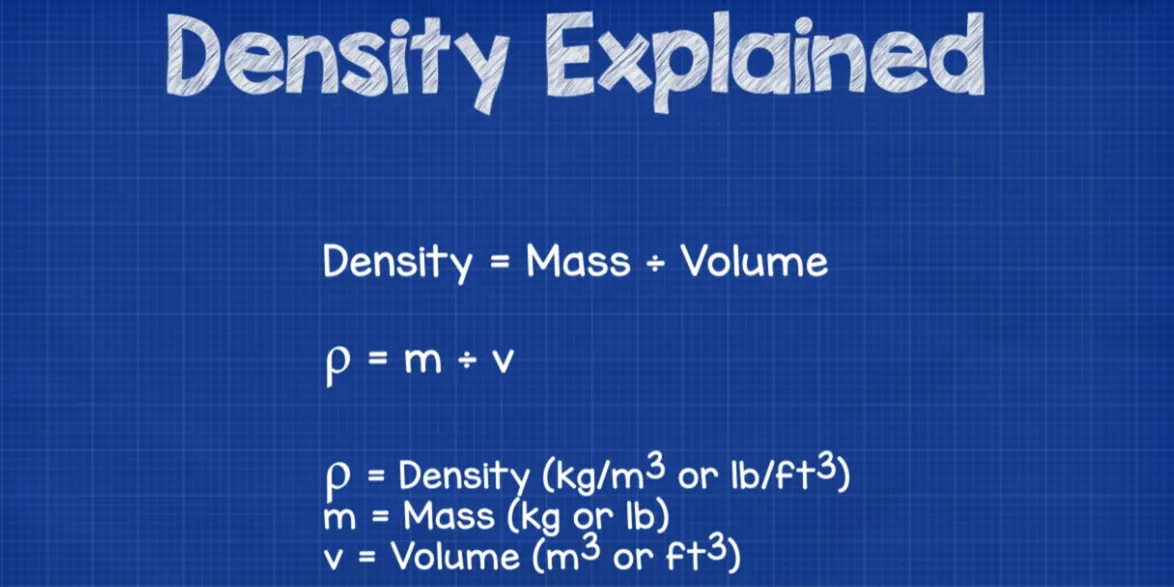

Definition of Density

It defines as the mass per unit volume of an object. To denote the density in unit, g/cm³ or kg/m³ is used.

Why does Density Matter?

Density remains the same without making any difference on material’s amount. It helps in determining whether the material will float like buoyancy or will sink in the water.

Importance of Density in Material Selection

Density must be known to design the product within a defined weight limit. It is identified by measuring volume and mass like buoyancy. In general, if a matter has low density, more material is required to perform a task, in case of fixed mass.

Equipment used to investigate the density of stainless steel.

In laboratory. Equipment used to measure density of steel are:

- Balance: to precisely measure the mass of specimen.

- Graduated cylinder: to determine volume.

- Thermometer: to control the temperature.

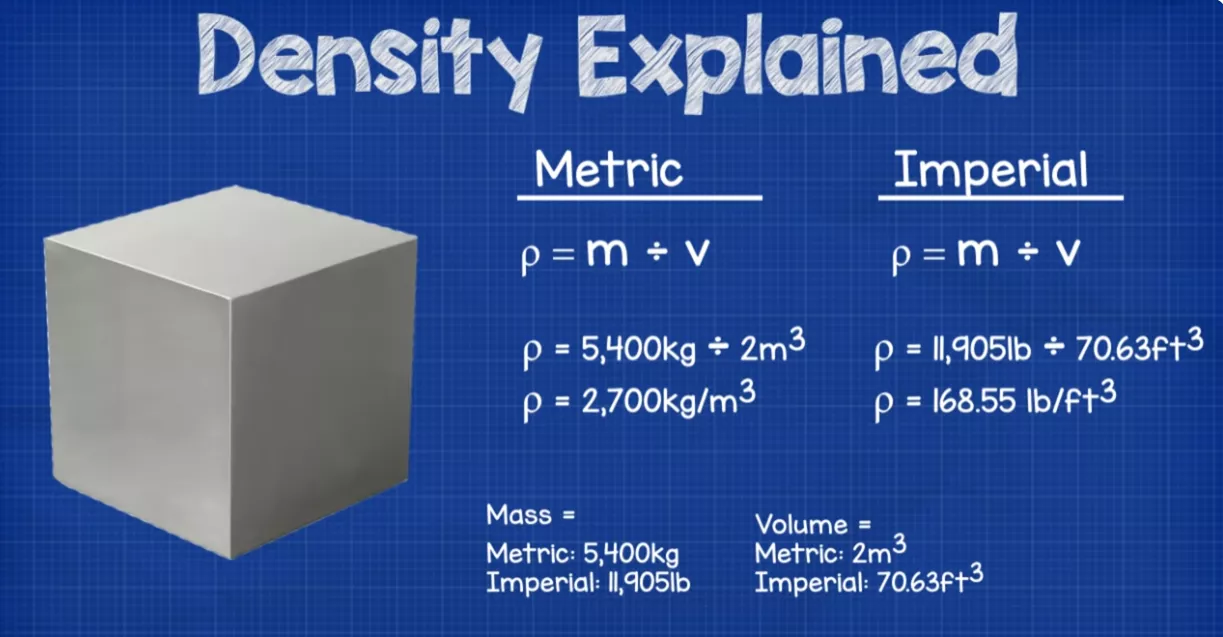

What are the Rules for Calculating Density?

To calculate the density, following formula must be used:

d= M/V

M= mass and V= volume. To precisely know the density, units must be used g/cm³ or kg/m³.

Density Values of Stainless Steel

Steel is a dense material. it is a reliable material for construction. Plain stainless steel has density around 7.85 g/cm³ or 7850kg/m³. Density of stainless steel varies depending on the alloying composition and grade.

General Density Range

Stainless steel has normally range of 7.5-8 g/cm³ density depending on the alloying elements.

Density by Type

- Austenitic Stainless Steels

Austenitic grades have normal density around 7.9 g/cm³

- Ferritic Stainless Steels

Ferritic grades have normal density of 7.7 g/cm³

- Martensitic Stainless Steels

Martensite grades have normal density of 7.8 g/cm³

- Duplex Stainless Steels

Duplex grades have normal density of 7.80g/cm³

Density of Common Stainless-Steel Grades

|

Steel grades |

Density |

||

|

g/cm³ |

kg/cm³ |

lb/in3 |

|

|

1018 |

7.87 |

7870 |

0.284 |

|

1030 |

7.85 |

7850 |

0.284 |

|

201 |

7.93 |

7930 |

0.286 |

|

301 |

7.93 |

7930 |

0.286 |

|

303 |

7.93 |

7930 |

0.286 |

|

304 |

7.93 |

7930 |

0.286 |

|

304L |

7.93 |

7930 |

0.286 |

|

316 |

7.98 |

7980 |

0.288 |

|

316L |

7.98 |

7980 |

0.288 |

|

321 |

7.93 |

7930 |

0.286 |

|

410 |

7.75 |

7750 |

0.280 |

|

410 |

7.75 |

7750 |

0.280 |

|

416 |

7.75 |

7750 |

0.280 |

|

420 |

7.73 |

7730 |

0.280 |

|

430 |

7.70 |

7700 |

0.278 |

|

440 |

7.74 |

7740 |

0.280 |

|

440c |

7.62 |

7620 |

0.275 |

|

446 |

7.7 |

7700 |

0.271 |

|

630 |

7.8 |

7800 |

0.280 |

|

2205 |

7.80 |

7800 |

0.282 |

Factors Affecting the Density of Stainless Steel

There are many factors that can affect the density of stainless steel severely. These are manufacturing process, temperature and pressure, materials properties, like buoyancy heat treatment and most importantly composition.

Composition Impact

If alloying element is heavier, it will increase the density of steel. Heavier metals like nickel and molybdenum increase the density. Metals like aluminum and titanium has less density and does not increase much of the density,

Manufacturing Processes

Increase in porosity and grain size during manufacturing can severely affect the density. High porosity creates less dense structure. Packing density is affected by the change in grain size. Highly packed structure has high density.

Application of Density in Stainless Steel Uses

It is essential to consider the effect of density features on the materials properties, like buoyancy corrosion resistance of steel to ensure to meet the requirements of material for specific application.

Material Selection in Engineering

Density is one of the important material properties during material selection. Stainless steel has variation in thickness. If the material density is known, it helps in selecting the best fit thickness of a material. for example, 304 has higher density than 316. Similarly, it has higher corrosion resistance and temperature resistance.

Weight Considerations in Construction

During construction weight considerations are vital. It indicates the efficiency of heat energy and building stability. It is helpful in preserving energy and land during construction.

Density Comparison with Other Metals

Density depends on the mass and volume. It is different for each material.

Stainless Steel vs. Aluminum

Aluminum has 2.81 g/cm³. stainless steel has 8 g/cm³. The strength to weight ratio of Al is ~99. Steel has less strength to weight ratio ~63.

Stainless Steel vs. Carbon Steel

Stainless steel has normally density of 8 g/cm³. It is heavier than carbon steel. average carbon steel has 7.85 g/cm³.

How to Use your Knowledge of Density While Selecting Materials

Density is used to determine the purity of a substance. It is to characterize and estimate the composition of combination of metals. This shows how much matter can occupy volume or its buoyancy at a definite range of temperature and pressure. If a material’s density is known, the substance can be identified.

How Tuofa China Can Help?

Important material properties in material selection are the material cost, material manufacturing, environmental impacts, and its chemical and physical properties. As we have discussed, density is one of the most important physical properties. TUOFA helps you in finding right material based on the material properties requirements. Tuofa CNC machining offers a range of materials with the right selection of manufacturing processes like sheet metal, CNC machining, 3D printing and many more. For more information, please visit: https://www.tuofa-cncmachining.com/

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

5083 Aluminum: Properties, Applications, and Machining Techniques

5083 Aluminum: Properties, Applications, and Machining Techniques