3Cr13 Steel: The Complete Guide

Jul 24,2024

Jul 24,2024

3Cr13 martensitic stainless steel has intrinsic metallurgical properties. These properties decide the category of the 3Cr13 item. One has to understand the edge retention and corrosion behavior of a knife. Edge retention decides the life and maintenance over the life span. Corrosion behavior tells about the medium of cutting.

Martensitic Stainless Steel applies to the cutting tool. It may decide the fate of your expensive cutting machine. Cutting operation ceases due to little knowledge about this material. Thus metallurgical understanding is the priority. 3Cr13 steel pressure low-strength pipe may fail. If application parameters are wrong. Application parameters always come from material properties.

What is 3Cr13 Steel?

This type of Stainless Steel has excess carbon in it. It has a high carbon and a strength of three hundred series. The easiest method is introducing carbon in low carbon Stainless Steel. Major alloying elements in this Martensitic Stainless Steel are Carbon, Chromium, and Nickle. Carbon imparts tensile strength & resistance to deformation. This property forms edge retention in knives. Chromium is famous for imparting oxide stability. Around 13 % chromium makes it corrosion-resistant. But this factor sacrifices the strength of the material. It has corrosion resistance and strength in it. Nickle is present in a very small amount of percentage. But it is enough to form tough properties.

Minor alloying elements do the same function. They remove the impurities from molten material. Sulfur in combination with manganese increases the machinability. Manganese sulfide can improve ductility. Finally, heat treatment improves the strength at termination. It inherits the corrosion resistance from chromium. Figure. No.1 shows the 3Cr13 knife.

Figure. No.1. 3Cr13 Knife.

Cr13 Steel Series: 6cr13, 4cr13 and 3Cr13

|

Steel Type |

Carbon Content |

Hardness |

Toughness |

Sharpening Ease |

Common Applications |

|

6Cr13 |

0.6% |

Highest |

Lower |

More difficult |

High hardness tools, blades requiring sharp edge retention |

|

4Cr13 |

0.4% |

Medium |

Medium |

Medium |

Multi-purpose tools, balance of hardness and toughness |

|

3Cr13 |

0.3% |

Lower |

Higher |

Easier |

Budget-friendly tools, emphasis on easy maintenance |

Pros and Cons of 3Cr13 Blade Steel

|

Pros |

Cons |

|

Affordable |

Poor edge retention |

|

Easy to sharpen |

Low hardness |

|

Good corrosion resistance |

Limited performance |

|

Tough |

What is 3Cr13 Stainless Steel Equivalent to?

3Cr13 (also known as 30Cr13) is a budget-friendly stainless steel commonly used in various applications due to its affordability and decent performance. Here's a table outlining its equivalents across different international standards:

|

Country/Region |

Standard |

Equivalent Grade |

|

China |

GB/T 1220; GB/T 3280 |

3Cr13 (30Cr13) |

|

USA |

AISI SAE; ASTM A276/A276M |

420 |

|

European Union |

EN 10088-2 |

X30Cr13 (1.4028) |

|

Japan |

JIS G 4303 |

SUS420J2 |

|

ISO |

ISO 15510 |

X30Cr13 |

Chinese Machining Services

Precision Engineering for Innovators

Send drawings to info@tuofa-cncmachining.com

Faster and Cheaper

3Cr13 Steel: Composition, Mechanical Properties and Heat Treatment

It has the best properties for field application. Hardness and corrosion resistance decide the exact product. A strength increase can decrease corrosion resistance. Wear resistance is proportional to the hardness of the material.

Chemical and mechanical parameters decide the material selection. Both parameters tell about material behavior. Chemical composition changes the hardness and strength of the material.

Hardness & Strength

It has approximately 55 HRC Hardness on the material surface. The material's Ultimate Tensile strength is more than 735 MPa. Material yields deformation at the stress of 540 MPa. These properties are best for structural materials with moderate corrosion resistance. In austenitic stainless steel, strength cannot go beyond 210 MPa. Even plain carbon steel cannot have yield strength beyond 250 MPa. This material has high strength of 540 MPa. Hardness increases surface retention and stability. And corrosion resistance comes from stable oxides at the surface. Hardness and strength come from high carbon content. In austenitic stainless steel, the carbon percentage is less than unity. Thus it cannot form martensitic phase reinforcement.

Corrosion Resistance

It is useful in applications of moderate corrosion environments. Even it resists atmospheric and aqueous corrosion. It resists corrosion in hardened tempered conditions. The strength and ductility advantage is great. Because every application requires strength. Although corrosion is also important for life stability. But strength with moderate corrosion resistance makes it great. In atmospheric and aqueous conditions it works well. It can resist dilute nitric acid attacks. Because chromium is not less than 12 percent in it. This quantity is enough to make a chromium oxide layer. And dilute nitric acid cannot break this layer.

Wear Resistance

Martensitic Stainless Steel has good wear resistance. It can shear and cut non-metallic items. Wear resistance comes from strength and hardness. High strength resists the surface crack formation process. Thus it has good fatigue properties. Because fatigue starts from the surface crack. Cyclic stress increases this crack formation. And it fails before the expected life span. Materials need maintenance for maintaining good wear resistance. But high wear resistance makes long life. High hardness maintains its surface profile. High force cannot deform the material. Corrosion resistance makes it stable for a time.

3Cr13 Steel Chemical Composition

Chemical composition is like Martensitic Stainless Steel. The carbon percentage lies in the middle of it. The high carbon percentage of this series is 1.20 percent. And the low carbon percentage is 0.15 percent. 3Cr13 lies between them. Chromium percentage also lies in the middle. Thus it has the best properties of the Martensitic Stainless Steel series. Carbon gives the greatest strength in it. So high-temperature sensitization does not occur. It has an application temperature of about 400 centigrade.

|

Chemical Composition (%) of 3Cr13 |

|

|

C |

0.26-0.35 |

|

Si |

1.0 maximum |

|

Mn |

1.0 maximum |

|

P |

0.040 maximum |

|

S |

0.030 maximum |

|

Ni |

0.60 maximum |

|

Cr |

12-14 |

Table. No.1.Chemical composition of 3Cr13.

3Cr13 Steel Mechanical Properties

Strength comes from the martensitic phase of 3Cr13. Carbon helps in the formation of this phase in it. Thus quenching and tempering results in high-strength material. Ductility comes from chromium percentage. Chromium helps in ferritic phase formation in the material. The ferritic phase makes good elongation and impacts energy in it. Strength gives edge retention to cutting items. Edge retention makes 3Cr13 knives stable for long life. And chromium prevents rusting of the surface. Chromium creates a balance between corrosion and ductility. 3Cr13 steel, a common medium-carbon stainless steel, is fairly machinable. China Tuofa’s innovative process is stainless steel machining.

|

Mechanical Properties of 3Cr13 |

|

|

Yield Strength, MPa |

540 minimum |

|

Tensile Strength, MPa |

735 minimum |

|

Percentage Elongation |

12 minimum |

|

Reduction in Area, % |

40 % |

|

Impact Energy, Joules |

24 joules |

Table. No.2.Mechanical Properties of 3Cr13.

Heat treatment

Martensitic phase allows quenching and tempering of material. Hardening gives strength to 3Cr13 material. Low tempering temperatures can increase strength. But low tempering temperatures can damage corrosion properties. Because chromium is sensitive to carbide formation. Thus tempering temperature of 600 centigrade is suitable. Annealing can improve ductility many times. But it does not bear stress in the application. Annealing can decrease the shearing force of cutting items. Thus it is useless in this condition.

|

Heat Treatment of 3Cr13 |

|

|

Unified numerical Code |

S42030 |

|

New Designation |

30Cr13 |

|

Old Designation |

3Cr13 |

|

Annealing Temperature |

800 to 900 Centigrade with furnace cooling |

|

Quenching Temperature |

920 to 980 Centigrade with oil quenching |

|

Tempering Temperature |

600-750 Centigrade |

Table. No.3.Heat Treatment of 3Cr13.

Is 3Cr13 good for Knives?

Good knife material is stable and strong. Stable material does not corrode with time. It does not lose its surface sharp edge. It should resist the fatigue phenomenon. Strong knife material has strength and ductility in it. Because knife material should cut items with flexibility. It can bend itself after striking the base shelf. These properties are the requirement of good knife material.

3Cr13 Martensitic Stainless Steel has these properties. It can resist the corrosive substances of kitchen items. It does not develop surface cracks. Thus it works with fatigue cycles. It yields at stress of 540 MPa. This can cut food items. 24 Joules impact energy makes it perfect for flexibility. It can elongate up to twelve percent before fracture. Thus it is good knife material.

3Cr13 for Different Types of Knives

Knives have classification due to application mechanism. It differs in shape for different purposes. Outdoor knife requires less space during transportation. The indoor knife needs a fixed shape.

Elk Ridge Knife: This knife requires cutting operation in at outside environment. It should have resistance to the humid and smoky atmosphere. This knife can perform hunting operations. Thus it needs material that can bear stresses more than normal conditions. It can bear collision with a hard surface. 3Cr13 Martensitic Stainless Steel can bear outdoor humid and smoky atmospheres. Thus it is suitable for elk ridge knife material.

Butterfly Knife: This knife material requires stability for a thin sheet. It requires corrosion resistance in a closed environment. This Stainless Steel can provide strength for thin material. It inhibits oxide formation in a closed environment.

Hunting Knife: A hunting knife requires strength for bone cutting. It requires sharp cutting with a thick metal sheet. It can provide extra strength with a high moment of inertia.

Folding and Pocket Knife: It needs foldability in a packed environment. 3Cr13 Martensitic Stainless Steel has good impact resistance for this job. It can maintain edge during folding operations.

Kitchen Knife: The kitchen knife needs edge retention and stability. 3Cr13 Martensitic stainless Steel has edge retention. It does not contaminate the kitchen food items. Thus it is suitable for kitchen knives.

Try Tuofa Now!

Custom solutions for complex designs: send drawings to info@tuofa-cncmachining.com

Real human quotes are more accurate than software quotes

3Cr13 VS 440c Stainless Steel

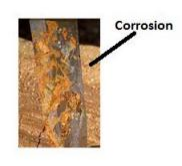

The carbon percentage is three times in 440c stainless steel. Thus it has more strength than 0.3 percent carbon stainless steel. But it loses corrosion strength in the environment. 440c cannot bear high corrosive environment. Figure. No.2 shows the corrosion of the 440c knife. 440c can form the bearing body. Because it needs strength with moderate corrosion resistance. 440c is brittle due to less ductility. Thus it cannot offer good flexibility in cutting operations. High cutting force can damage the 440c blade. A comparison of properties is presented in Table. No.4.

Figure. No.2 Corrosion in 440c Knife.

|

Property |

440c |

3Cr13 |

|

Carbon |

0.95 - 1.20 |

0.26-0.35 |

|

Chromium |

16 - 18 |

12-14 |

|

Tensile Strength MPa |

>1500 MPa |

> 735 MPa |

|

Elongation |

14 % |

12 % |

Table No.4. 3Cr13 Vs 440c Stainless Steel.

Applications of 3Cr13 Steel

- Cutlery and kitchen knives: 3Cr13's corrosion resistance and stability make it suitable for food processing, where it can withstand stresses and repeated cutting without contaminating food.

- Pipes and fittings: 3Cr13's strength and corrosion resistance make it ideal for pipes and fittings carrying liquids or gases, even in demanding environments where maintenance is difficult.

- Cutting tools: 3Cr13's stability and strength, coupled with its corrosion resistance, make it a good choice for cutting tools that need to remain clean and free of loose particles.

Maintenance and Care Tips for 3Cr13 Stainless Steel

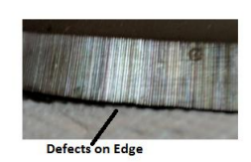

3Cr13 can resist a corrosive atmosphere. But it does not support acidic media. If it undergoes an acidic environment for a long time. Then it can lose a sharp surface. Figure. No.3 shows edge defects in it. It may suffer from blistering. It needs maintenance in this case. Surface finishing is the best option for this problem. 3Cr13 does not need maintenance in an ordinary environment.

Figure. No.3. Edge Defects of Knife.

Conclusion

3Cr13 is the optimum material for cutting items. It can resist the corrosion attack and stress cycle. It needs less maintenance for continuous application. Ordinary carbon steel cannot provide strength and corrosion resistance at once. But 3Cr13 can offer both properties at the same time. It does not need expensive processes. Ordinary product has a long life. Thus it is a good option for knives and cutting tools.

FAQs

3Cr13MoV vs. 3Cr13 Steel

3Cr13MoV is a modified version of 3Cr13 with added molybdenum and vanadium. These additions improve hardness and edge retention slightly but also increase the cost.

|

Feature |

3Cr13MoV |

3Cr13 |

|

Composition |

Carbon (0.3%), Chromium (13%), Molybdenum, Vanadium |

Carbon (0.3%), Chromium (13%) |

|

Hardness |

Slightly higher |

Lower |

|

Edge retention |

Slightly better |

Poor |

|

Corrosion resistance |

Similar |

Similar |

|

Cost |

Slightly higher |

Lower |

3Cr13 Stainless Steel vs. 420 Stainless Steel

3Cr13 and 420 are considered equivalent steels, with very similar properties and performance. The choice between them often comes down to availability and brand preference.

|

Feature |

3Cr13 |

420 |

|

Composition |

Carbon (0.3%), Chromium (13%) |

Carbon (0.15-0.40%), Chromium (12-14%) |

|

Hardness |

Similar |

Similar |

|

Edge retention |

Similar |

Similar |

|

Corrosion resistance |

Similar |

Similar |

|

Cost |

Similar |

Similar |

14C28N vs. 3Cr13 Steel

14C28N is a high-performance steel specifically designed for knives. It significantly outperforms 3Cr13 in terms of hardness, edge retention, and corrosion resistance, but it is also more expensive.

|

Feature |

14C28N |

3Cr13 |

|

Composition |

Carbon (1.1%), Chromium (14%), Nitrogen (0.11%) |

Carbon (0.3%), Chromium (13%) |

|

Hardness |

Much higher |

Lower |

|

Edge retention |

Excellent |

Poor |

|

Corrosion resistance |

Excellent |

Good |

|

Cost |

Higher |

Lower |

3Cr13 Vs D2

D2 tool steel has high carbon and strength. It has applications in cutting items. But it cannot bear rusting. Because it has high carbon in it. The high-strength application requires D2 Steel. It can perform in a low-corrosive environment. Thus corrosion resistant cutting requires 3Cr13. A comparison of properties is presented in Table. No.6.

|

Property |

D2 |

3Cr13 |

|

Carbon % |

1.40-1.60 |

0.26-0.35 |

|

Chromium % |

11 - 13 |

12-14 |

|

Tensile Strength MPa |

> 1500 MPa |

> 735 MPa |

|

Elongation % |

16 % |

12 % |

Table No.6. 3Cr13 Vs D2 Steel.

Is 3Cr13 Steel good for Sword?

3Cr13 Martensitic Stainless Steel is the best option for the sword. It offers resistance to corrosion in outdoor environments. High-carbon steel swords cannot resist rusting. Because high carbon corrodes steel. The sword needs corrosion resistance in an outdoor environment. Thus 3Cr13 is the best option.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Lug Bolts Vs Lug Nuts: What is the Differences Between

Lug Bolts Vs Lug Nuts: What is the Differences Between