Grades of Titanium | Properties and Uses to Easy Guide

Jan 25,2024

Jan 25,2024

Titanium metal is known for their exceptional strength to weight ratio with the symbol Ti. Grades of titanium have different properties and are used in different applications. Titanium material grades from 1 to 4 are very good corrosion resistors that’s why used in chemical processes applications. Titanium use in aerospace industry is grade 5 which combined low weight and strength. Medical grade titanium is 2 has excellent biocompatibility. Different types of titanium are used for different serving industries, aviation and health care applications. ASTM B265 is used for quality and uniformity of list of titanium alloys having sheets and plates shapes. While ASTM B348 is used for bars and billets types of titanium quality Esurance.

Titanium Material Composition

Titanium metal has robust material composition it has 22 proton and electron. Titanium metal is light weight with 47.87 weight and has a crystalline structure. There are different available list of titanium alloys including elements like vanadium, nickel, aluminum for different variety of applications.

Titanium in Raw form.

Is Titanium Flexible?

Titanium has best comparison between strength and flexibility making it moderately flexible. Titanium material grade Ti-6Al-4V has high flexibility comparison to other making it suitable for application where flexibility is required.

Is Titanium an Alloy?

Yes, there are list of titanium alloys available depending on properties of different titanium grades they are used in specific applications.

Is Titanium Malleable?

Yes, titanium is malleable but its malleability depends upon the alloy composition and technique used to process it.

How Titanium is Made

Titanium metal is processed by reducing titanium tetrachloride with in to sponge like structure of titanium from magnesium. This process is named as Kroll process. Similar to Kroll process the titanium metal can also be processed by Hunter process in which titanium tetrachloride is reduced with sodium.

Figure: Titanium metal.

Heat Resistance

Titanium metal and titanium material grades are best known for heat resistance. They can maintain their structural integrity at high temperature. Titanium metal has high melting point of 3034 degree.

Density

Titanium metal has half the density of steel. Titanium metal low weight and high strength ability make it suitable for aerospace applications. Pure titanium has density of 4.506 g/cm3.

Ultimate Tensile Strength

Titanium How Strong

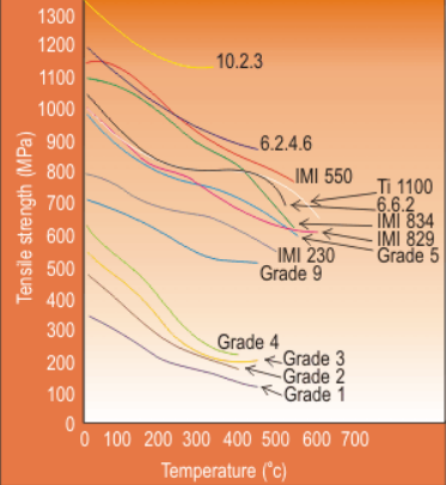

Different titanium grades have different tensile strength. Titanium grade comparison with pure having 240-550 M pa (grade 1 to 4) the titanium grade Ti-6Al-4V has max strength of 900 M pa or even more.

Figure: Tensile stress of different titanium graph at elevated temperature

Titanium Categories

There are two types of titanium in general.

Titanium Grades Explained

CP Titanium – Commercially Pure Titanium

It includes titanium material grades from 1-4. These titanium grades comparison to other has fewer alloying elements. These titanium grades have excellent resistances’ corrosion and has strength and ductility of varies range.

|

Categorization |

Grades of Titanium |

|

Alpha-alloy |

|

Titanium - Based Alloys

These titanium grades comparison to other has high mechanical property and toughness are mainly used in medical and aerospace application. They have alloying elements like aluminum, nickel and vanadium.

|

Categorization |

Grades of Titanium |

|

Near Alpha-alloy |

|

|

Alpha-Beta Alloy |

|

|

Beta Alloy |

|

Table shows major classification of titanium alloys category

CP Titanium

Grade 1 Titanium

Grade 1 is the purest type of titanium with 99.5%. It possesses good formability, corrosion resistance and weldability. This titanium material grade is used in application like chemical possessors, marine components and medical implants. ASTM B265 and ASTM B348 ensures the uniformity and quality of manufacturing. This grade of titanium is available in different shapes like bars, tubes plates depending upon the application. More information about grade 1 titanium.

YouTube video of Kroll process

Grade 2 Titanium

Second grade of titanium is 99 percent of titanium. This Titanium grade comparison to grade 1 is slightly stronger. Have high corrosion resistance, formability, weldability properties. This titanium is also known as medical grade titanium and also used in Marin application. ASTM B265 and ASTM B348 ensures the uniformity and quality of manufacturing. This grade of titanium is available in different shapes like bars, tubes plates depending upon the application

Grade 3 Titanium

Grade 3 titanium metal has 98 percent of titanium and has more corrosion resistance compare to grade 1 and grade 2. This grade is also used in aerospace application and Marin application. For quality Esurance ASTM B265 and ASTM B348 are used. This grade of titanium is available in different shapes like bars, tubes plates depending upon the application

Grade 4 Titanium

4th trade of titanium also contains 0.5 palladium making it highly corrosion resistive. This grade of titanium is highly recommended in chemical processors, distillation plants and marine component due to property requirement of high corrosion resistance. For uniformity and quality Esurance ASTM B265 and ASTM B348 are used.

Grade 7 Titanium

Grade 7 titanium metal contains 0.12 to 0.25 percent of palladium, 0.3 percent of iron, 0.25 percent of oxygen and some other elements. Grade 7 of titanium shows excellent corrosion resistance, weldability and forming properties. This titanium grades comparison to other have very high corrosion protection that’s why used in chemical reactors and destination applications. For quality Esurance ASTM B265 and ASTM B348 are used. This titanium metal grade is available in different shapes like tubes, plates, sheets bars and other.

Grade 11 Titanium

Titanium material grade 11 also known as CP Ti-0.15Pd has 0.2-0.4 percent palladium. It has good ductility, impact toughness and very high crevice corrosion resistance due to high content of palladium. ASTM B265 and ASTM B348 ensures the uniformity and quality of manufacturing. This type is used in heat exchangers, pimps, ducts, and storage chemical processors. This titanium metal grade is available in different shapes like tubes, plates, sheets bars and other.

Common Titanium Based Alloys

Ti-6Al-4V Grade 5

This type of titanium is high strength titanium belongs to alpha-beta titanium material grade. It consists of 4 percentage of aluminum and 4 percent of vanadium. It has low density, strength and high corrosion property. This type of titanium is used in aircraft components, space craft structures due reduced weight property contributes to the fuel efficiency in aerospace applications. It is also used in medical implants due to low reactivity to human body, Marin applications and sports equipment manufacturing. Common standard for bars and billets of this type of titanium grade is ASTM B348 while for wrought form of this grade for surgical implant application ASTM F136 standard is used.

Ti-5Al-2.5Sn - Grade 6

This grade of titanium 5 percent aluminum 2.5 percent tin. This type of titanium has good strength, weldability, and corrosion resistance due to presence of tin. These diverse applications make it suitable for different applications like chemical processing, marine engineering and aerospace application. For quality insurance ASTM B265 and ASTM B348 is used. It is present in the form of bars, sheets, plates, billets and tubes.

Ti-3Al-2.5V - Grade 9

Grade 9 type of titanium alloy consist of 2.5 percent of vanadium and 3 percent of aluminum this belongs to alpha-beta alloy category. This titanium material grade has combined properties having good balance of weldability, strength and corrosion resistance. This type of titanium metal is used in chemical processes, aerospace application, sports equipment and biomedical devices. ASTM standard B265 is used for plate, sheets and strip shapes. While ASTM B348 is used for billets and bars.

Ti-0.3-Mo-0.8Ni - Grade 12

As from different list of titanium alloys this type has 0.8 percent nickel and 0.3 percent of molybdenum. It contains combined characteristics of molybdenum and nickel. Molybdenum provides corrosion resistance and increased strength while nickel enhance the toughness but also improve corrosion resistance. They are used in different applications depending on the desired properties. Quality Esurance and properties consistency can be standardized by ASTM B265 and B348. It is present in the form of tubes, sheet, bar and plates.

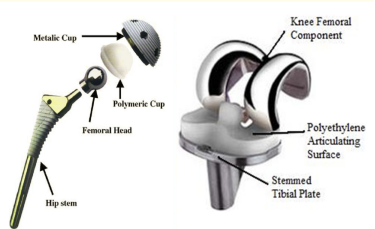

Titanium in biomedical implants

Ti-10V-2Fe-3Al

This titanium grade comparison to other have 10 percent of vanadium 2% iron and 3 % aluminum. This type of titanium belongs to beta category have high corrosion resistance, heat resistant and strength. This Titanium in aerospace industry is used in aircraft landing gear. This grade is also known as medical grade titanium used in surgical instruments and orthopedic implants. Also due to corrosion resistance property they are used in chemical processing equipment. For standard quality ensures ASTM B265 and ASTM B348 is used. They are available in the form of bars and billets for fasteners and connectors manufacturing. Also available in the plates, tubes and sheet form for aerospace and chemical industry.

Ti-5Al-5V-5Mo-3Cr

This titanium grade comparison to other have very high strength, heat resistant and corossion resistance. It consists of 5 percent aluminum, 5 percent vanadium and 5 percent molybdenum and 3 percent chromium. It also falls in alpha beta category of alloys. This type of titanium in aerospace industry is used for manufacturing engine components and structural elements. Also used in military applications because can survive harsh environment. Due to high corossion resistance can be used in chemical processes equipment and Marin industry.

Figure showing titanium screws and other components.

Titanium Alpha Alloys

Defining

This Titanium material grade is known as alpha alloy because it consists of alpha phase titanium. This alloy mainly has tin and aluminum as major alloying element. Alpha alloys have weldability, formability and high corrosion resistance to oxidizing environment. Has microstructure of hexagonal close packing alpha phase.

Used in manufacturing of aerospace Components, chemical Processing and biomedical Implants.

Standards

ASTM B265: quality Esurance of sheets and plate.

ASTM B348: used for quality Esurance of bars and billets.

Forms Available

This type of titanium is available in the form of bars, billets, plate, sheets and tubes.

Titanium Beta Alloys

Beta titanium alloys are a beta phase body centered cubic crystal structure. These alloys have good corossion resistance, high strength to weight ratio and good formability. These types of titanium are also used in aerospace industry, automotive industry and biomedical implant. Different standard is used for beta titanium alloys some of them are ASTM B265, ASTM B348, ASTM B861, ASTM B862 and ASTM 136. They are available in different forms like casted, forged, wires, bars, billets, sheets, plates, tubes and pipes.

|

Alloy name |

UNS Number |

Condition |

Yield strength |

Tensile strength |

Elongation |

Reduction of Area |

NACE MRO 175 |

|

Grade 2 |

R50400 |

Anneal |

40 |

50 |

20 |

88-100Rb |

100Rb Max |

|

Grade 7 |

R52400 |

Anneal |

40 |

50 |

20 |

88-100Rb |

no |

|

Grade 12 |

R53400 |

Anneal |

50 |

70 |

18 |

88-100Rb |

92Rb Max |

|

Grade 9 |

R56320 |

Anneal |

70 |

90 |

15 |

24-28Rc |

NO |

|

Grade 5 |

R56400 |

Anneal |

120 |

130 |

10 |

28-35Rc |

NO |

|

Grade 28 |

R56323 |

Anneal |

70 |

90 |

15 |

24-32Rc |

32Rb Max |

|

Grade 29 |

R56404 |

Anneal |

110 |

120 |

10 |

28-35Rc |

35Rb Max |

|

6AL-6V-2Sn |

R56620 |

Anneal |

135-160 |

147-170 |

8-12 |

28-36Rc |

NO |

|

6AL-6V-4Zr-6Mo |

R56260 |

Solution treat +age |

130-165 |

145-175 |

6-20 |

35-45Rc |

45Rb Max |

|

Grade 19 (Beta-C) |

R58640 |

Solution treat +age |

115-180 |

120-190 |

5-20 |

32-45Rc |

42Rb Max |

Table showing properties of different titanium alloys.

Heat Treatment

Titanium heat treatment is done to change the micro structure to improve the Mechanical properties of titanium and different types of titanium alloys. Strength, hardness and ductility can be modified by specific heat treatment. There are different heat treatments which can be some of them are listed below.

- Annealing

- Aging

- Beta Annealing

- Stress Relief Annealing

- Duplex Annealing

How to Choose the Right Grade

Depending upon the alloys grade every grade has different properties that make it special for particular application. So, the right grade can be chosen by comparing the properties of all available grades. The one which has best properties for that specific application would be Selected.

Why Choose Tuofa Custom Titanium Parts

China Tuofa's extensive range of titanium materials, suitable for various industries, offers the durability and corrosion resistance you need. You will appreciate our advanced CNC machining capabilities. Because:

Precision in crafting complex parts is critical for your applications, and our technology ensures this accuracy.

Moreover, we value our commitment to quality. In terms of material review, we comply with international standards such as ASTM B265 and ASTM B348. In the absence of additional requirements, we will strictly complete your specified requirements by ISO 2768 CNC machining standards. The pursuit of perfection is our only goal for machining services

Now send part drawings to info@tuofa-cncmachining.com, let our engineers work with you, and great ideas will come out.

FAQs

Grade 2 Titanium vs Grade 5

Grade 2 titanium is commercially pure titanium with excellent corrosion resistance and weldability, making it suitable for chemical processes. Grade 5 titanium (Ti-6Al-4V) is an alloy of aluminum and vanadium that has increased strength and is widely used in aerospace, medical facilities, and high-performance applications. This alloy has increased strength but reduced hardness compared to Class 2 alloys.

The Toughest Titanium Alloy

Grade 5 titanium, also known as Ti-6Al-4V, is hailed as one of the strongest and most extensively used titanium alloys. Comprised of 6% aluminum (Al) and 4% vanadium (V), this alloy combination boasts robustness, low pressure, and excellent resistance against corrosion. It finds wide application in the aerospace, medical, and industrial sectors, where a delicate balance between strength and weight is crucial.

ASTM F136 Titanium versus G23

ASTM F136 Titanium and G23 Titanium are alloys employed in diverse industries. F136 is a surgical implant that adheres to rigorous ASTM standards for biocompatibility. Meanwhile, G23, utilized in body jewelry, possesses a similar composition but lacks official regulations. Adherence to specific application guidelines is imperative to ensure the safety and quality of their usage.

Distinct Grades of Titanium Tubing

Titanium tubing is available in an array of grades, each tailored to a specific application. The most prevalent grades for titanium tubes encompass grade 2 (purely industrial), grade 5 (Ti-6Al-4V, for aerospace and medical purposes), grade 7 (Ti-0.15Pd, resistant to corrosion), and grade 9 (Ti-3Al-2.5V, high-powered). The choice of grade hinges upon the desired performance for the intended use.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

416 Stainless Steel Material Properties | 400 Series Stainless

416 Stainless Steel Material Properties | 400 Series Stainless