The Beginner’s Guide to 2205 Duplex Stainless Steel

Jan 15,2024

Jan 15,2024

Here is the beginner's guide to 2205 duplex stainless steel where you can explore the world of 2205 duplex stainless steel. This stainless steel is all about having a material that is incredibly strong and resistant to corrosion. Our goal is to make you able to understand the type of material for your specific application. You need to know about the unique and balanced set of properties this stainless-steel holds. Through this, you will learn about its capabilities and the reasons behind its wide use in everyday applications. In this article, we will investigate the basic concepts, properties, pros, and cons of 2205 duplex stainless steel.

What is 2205 Duplex Stainless Steel

2205 Duplex Stainless Steel is well known for its strength, durability, and corrosion resistance. The word 'Duplex' stands for the dual phase of alloy 2205, as its microstructure shows two phases, one is ferritic which is chromium and molybdenum phase, and the other one is austenitic which is chromium and nickel phase [2]. The reason behind its exceptional response to corrosion, especially pitting and crevice corrosion, is the presence of alloying elements such as chromium and molybdenum. 2205 Stainless Steel performs well under harsh environment and is widely employed in high-end industries including oil & gas, and marine construction. It is to be noted that duplex 2205 composition shows not that much of alloying content to be called as super duplex 2205 since, super duplex is another type of duplex stainless steels having greater alloying content.

Terminology and Identifiers of 2205 stainless steel

2205 Duplex Stainless Steel also known as RA 2205 can be defined by terms and identifiers that indicate its composition and qualities. Its composition is indicated by the "2205" in its name; normally, it is composed of approximately 22 percent chromium, 5-6% nickel, 3% molybdenum, and roughly 2.5% nitrogen. For 2205 duplex stainless steel, following designations are being used:

- Under the Unified Numbering System, the designation for duplex 2205 is UNS S32205.

- Under ASTM standards, the designation for duplex SS 2205 is A240 or A240M for duplex 2205 pipe.

- Under European Norm, the designation for alloy 2205 is EN 1.4462.

Is 2205 stainless steel Magnetic?

Since 2205 duplex stainless steel consists of dual phase microstructure which is ferritic and austenitic. The presence of ferritic phase is responsible for its magnetic properties as austenitic are generally non-magnetic. Hence, duplex SS 2205 is magnetic. However, these magnetic properties can be modified depending on heat treatment processes. For example, when annealing is done in case of alloy 2205, the ferritic phase is up to 50% . More the ferritic phase, more will be the magnetic property.

Different Forms of duplex 2205 steel

UNS S32205 is generally available in following forms:

- Sheets

- Plates

- Wire

- Bars

- Rods

- Pipes and Tubes

- Fittings, etc.

The use of these available forms depends on your specific application. For example, sheets and plates type 2205 alloy has its applications in construction and manufacturing industries. Similarly, bars and rods have their applications in oil and gas industries. Moreover, fittings such as elbows and tees are used in industries for connecting pipes, etc.

Chinese Machining Services

Send drawings to info@tuofa-cncmachining.com

Faster and Cheaper

The Resistance Profile of Alloy 2205 Stainless

2205 duplex stainless steel has an exceptional resistance profile compared to other stainless steels. It performs well under every environment whether it is harsh or corrosive, which makes its extensive use in a number of applications.

Heat Resistance

2205 duplex stainless steel offers good resistance to oxidation at higher temperatures. This property is known as scaling resistance. That makes it useful for some high temperature applications.

2205 alloy also performs well under creep environment till certain temperature range because of its excellent strength and it has a good coefficient of thermal expansion.

Generally, 2205 duplex stainless steels are used below 300°C, because if they are being used above this temperature it leads to embrittlement of this stainless steel.

Corrosion Resistance

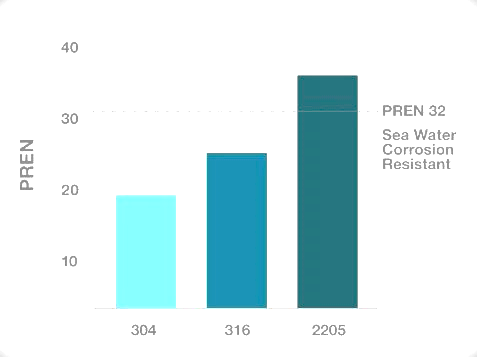

Usually, it is being considered that SS 316L is the best material for corrosive environment. However even this material can corrode over time. The one material that’s held up under the most intense condition is 2205 duplex stainless steel also known as UNS S31803/S32205. Each material has its own level of corrosion resistance which the steel industry describes as a rating system called the Pitting Resistance Equivalency Number. In order to be fully corrosion resistance under marine environment, the material should have at least 32 rating on PREN scale. Our duplex 2205 has a rating of around 35 which is higher than the requirement. It is also called duplex because of its excellent corrosion properties along with its strength that’s why it is being popular material for many applications.

Graph showing PREN rating for different materials.

The reason behind its corrosion resistance is the presence of alloying elements such as molybdenum, nitrogen, and chromium. The presence of molybdenum is the main reason behind the resistance to saline environment and resistance towards pitting and crevice corrosion that are being considered as dangerous types of corrosion. Similarly, the presence of chromium protects this material from atmospheric corrosion by forming a protective oxide layer which is accompanied by the presence of nitrogen making the protective layer more stable under harsh conditions.

Also, the presence of dual phase imparts a uniformity across the whole material which helps in avoiding stress concentration zones and for that reason duplex SS 2205 has good resistance to stress corrosion cracking.

Following video shows the corrosion resistance properties of 2205 duplex stainless steel,

Duplex 2205 Composition

2205 duplex is an alloy steel due to the presence of certain alloying elements like chromium, manganese, silicon, phosphorous, molybdenum and sulfur. It is often heat-treated to obtain desired properties.

Following table contains the duplex 2205 composition:

|

Elements |

Content |

|

Carbon |

Up to 0.03 % |

|

Molybdenum |

2.5- 3.5 % |

|

Manganese |

Up to 2.0 % |

|

Silicon |

Up to 1.0 % |

|

Phosphorous |

Up to 0.03 % |

|

Chromium |

Up to 23 % |

|

Nickel |

4.5- 6.5 % |

|

Nitrogen |

0.14- 0.20 % |

|

Sulfur |

Up to 0.02 % |

Physical Properties of 2205 Stainless Steel

The following table shows the values of physical properties of duplex SS 2205:

|

Properties |

Value |

|

Density |

7.80 (g/cm3) |

|

Melting Point |

1390- 1450°C |

|

Thermal Conductivity |

19 (W/m.K) |

|

Specific Heat Capacity |

450 (J/ Kg.K) |

|

Electrical Resistivity |

7.5- 8.5 (µΩ·m) |

|

Coefficient of Thermal Expansion |

13- 14 (µm/m/°C) for 0- 100°C |

|

Elastic Modulus |

200 (GPa) |

2205 Stainless Steel Mechanical Properties Chart

The following table shows the values of mechanical properties of duplex SS 2205:

|

Properties |

Value |

|

Tensile Strength |

620 (MPa) |

|

Elongation |

25 % |

|

Yield Strength YS |

450- 550 (MPa) |

|

Brinell’s hardness value |

290 |

|

Rockwell’s hardness value |

31 |

Manufacturing Process of 2205 Stainless Steel

Heat treatment

To improve the properties of 2205 duplex stainless steel, annealing can be done which is then followed by rapid cooling. The temperature range for annealing process of alloy 2205 is around 1020 to 1080°C. This would result in optimizing its microstructure in order to improve its strength and other properties. However, this material has less ductility compared to austenitic stainless steels due to the presence of ferritic phase but has higher strength. One important thing to note is that heat treatment is difficult for duplex ss 2205 but can be work hardened.

Welding

Comparatively, 2205 duplex stainless steel shows better weldability than other stainless steel. The welding can be performed by almost all the general welding techniques including SMAW, GTAW, GMAW and MIG, etc. However, it is important to understand that temperature is recommended to be below 300°C, as above this temperature embrittlement starts to occur in 2205 alloy. Also make sure to follow some general rule when welding duplex stainless steel which includes, using such filler material containing nitrogen and nickel as an alloying element and using large root gaps.

Machining

Compared with ordinary stainless steel or other materials, CNC machining of 2205 alloy may require finer parameter adjustment and a higher technical level.

Because of the below mentioned reasons:

- Due to its strong tensile strength and high yield point, duplex is generally difficult to machine. However, a higher ferrite percentage (over 60%) enhances machinability.

- Strong chips from machine can result in chip crushing and high cutting forces.

- Cutting produces a lot of heat, which can cause plastic deformation and severe crater wear.

For this purpose, cutting speeds should be kept low to avoid tool breakage and efficient machining.

Following table shows the recommended values of certain machining operations:

|

Operations |

Values |

|

Turning |

350- 450 SFM |100-140 m/min |

|

Milling |

200- 300 SFM | 60- 85 m/min |

|

Drilling |

100- 125 SFM | 30- 40 m/min |

|

Parting |

125- 180 SFM | 40- 60 m/min |

The following video shows milling operation on 2205 duplex stainless steel,

Standard Finish

Obtaining a good surface finish is among the final touches in the process. There are different designations for stainless steels however, the few most common and related finishes for duplex SS 2205 are:

No. 1: Hot-rolled, annealed, and descaled. This finish is often used in industrial applications where heat and corrosion resistance are required.

No. 2B: Cold-rolled, annealed, and pickled. Most popular duplex SS 2205 smooth and reflective finish.

Bright Annealed: This finish produces a bright, reflecting surface by annealing in a controlled environment. Mostly used in applications where aesthetics is needed.

2205 stainless steel casting

What is 2205 Stainless Steel Used For

2205 duplex stainless steel has applications in the following industries:

- Chemical processing

- Oil and Gas Industry (Equipment)

- Marine Components manufacturing

- Pulp and Paper Industry (piping system and heat exchangers)

- Construction (Building components)

- Aerospace Industry (components and fasteners)

- Automotive Industry (Exhaust systems)

Try Tuofa Now!

Send drawings to info@tuofa-cncmachining.com

Real human quotes are more accurate than software quotes

Pros and Cons of SS 2205 Material

Advantages

- 2205 duplex stainless steel offers much greater strength compared to other austenitic stainless steel.

- Due to its dual phase microstructure, it offers both the strength of one material and resistive properties of the other material.

- It offers good impact resistance and good toughness.

- It performs good under cyclic loading.

- It has lower thermal expansion and avoids expansion and contraction under harsh environments.

- Since it is being used for high end applications, it is cost effective compared to other materials.

Limitations

- Due to the presence of ferritic phase, it has less ductility compared to austenitic stainless steels.

- Because of its greater strength and hardness values, its machinability is relatively difficult.

- Since the machining requires specific tools and welding requires specific filler material, it might make the machining and welding of this material comparatively expensive in some cases.

- Embrittlement occurs at temperatures greater than 300°C in a short period.

Conclusion

UNS S31803/S32205 has a balanced set of properties including resistance to corrosion and high strength. It has a dual phase microstructure consisting of both ferritic and austenitic phases, to be used for several applications. Duplex SS 2205 is an economical option for various applications. Its versatile nature can be determined by the number of characteristics it offers involving its resistance to stress corrosion cracking, remarkable toughness, and compatibility with a range of manufacturing processes. 2205 alloy is the most important industrial material, which is durable, sustainable, and efficient for many purposes.

China Tuofa Stainless Steel Machining Capabilities

Discover precision with China Tuofa - your destination for unparalleled stainless steel machining capabilities. At Tuofa, we blend cutting-edge technology with expert craftsmanship to transform stainless steel into intricate, high-quality components. Our commitment to excellence shines in every project, ensuring your visions are realized with utmost accuracy and efficiency. Whether it’s aerospace engineering or medical technology, we cater to diverse industries with tailored solutions.

Contact us today to start your project today, send drawings to info@tuof-cncmachining.com

FAQs

How to Weld 2205 Duplex Stainless Steel?

To weld UNS S31803/S32205, consider cleaning the workpiece, using a filler material containing nitrogen and nickel, and controlling heat generation to avoid high-temperature embrittlement.

2205 Stainless Steel Compared to SS 316?

Differences include 316's austenitic structure vs. 2205's dual-phase structure, 2205's superior corrosion resistance, and 316's better weldability. Duplex SS 2205 is more expensive due to more alloying elements.

2205 Stainless Steel Compared to SS 304?

SS 304 is austenitic, while SS 2205 has a dual-phase structure. Alloy 2205 has superior corrosion resistance and strength, but SS 304 has better weldability.

Equivalent of 2205 Stainless Steel?

UNS S31803 is equivalent to UNS S32205. The duplex stainless steel is mainly referred to as UNS S31803/S32205.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Grades of Titanium | Properties and Uses to Easy Guide

Grades of Titanium | Properties and Uses to Easy Guide