Xometry Materials vs Tuofa: A Comparative Analysis for CNC Machining Needs

Aug 09,2024

Aug 09,2024

In the realm of CNC machining, material isn't just a component; it's the foundation of success. The right material dictates a product's strength, longevity, and cost-efficiency. Join us as we explore the material pages and capabilities of Tuofa and Xometry, equipping you with the knowledge to make material choices that guarantee optimal results.

Material Selection Factors for CNC Machining

Before diving into the comparison, let's briefly review the key factors that influence material selection for CNC machining:

- Strength and Durability: The material's ability to withstand mechanical stress, wear, and tear is critical for many applications.

- Weight: In industries like aerospace and automotive, lightweight materials are often preferred to improve fuel efficiency and performance.

- Corrosion Resistance: For components exposed to harsh environments, materials resistant to corrosion and oxidation are essential.

- Machinability: The ease with which a material can be cut, shaped, and finished affects production time and cost.

- Cost: The material's price and availability can significantly impact the overall project budget.

Evaluation of Tuofa's Material Pages

Material Variety

Tuofa's material page presents a curated selection of commonly used materials for CNC machining, including metals, plastics, and composites. While the list is not exhaustive, it covers a wide range of applications, from general engineering to aerospace and medical devices. Compared to Xometry, Tuofa's material variety may appear somewhat limited, but it focuses on providing in-depth information on the materials it specializes in.

Material Information

Tuofa excels in providing detailed and informative material descriptions. Each material is accompanied by its key properties, specifications, and typical applications. The information is presented in a clear and concise manner, making it easy for users to understand the material's suitability for their specific needs. Additionally, Tuofa includes high-quality images of machined parts made from each material, showcasing their capabilities.

Search and Filter Options

Tuofa's material page lacks advanced search and filter options. Users can only browse the materials alphabetically or by category. This limitation might make it slightly time-consuming to find specific materials, especially if the user is unsure about the exact name or category.

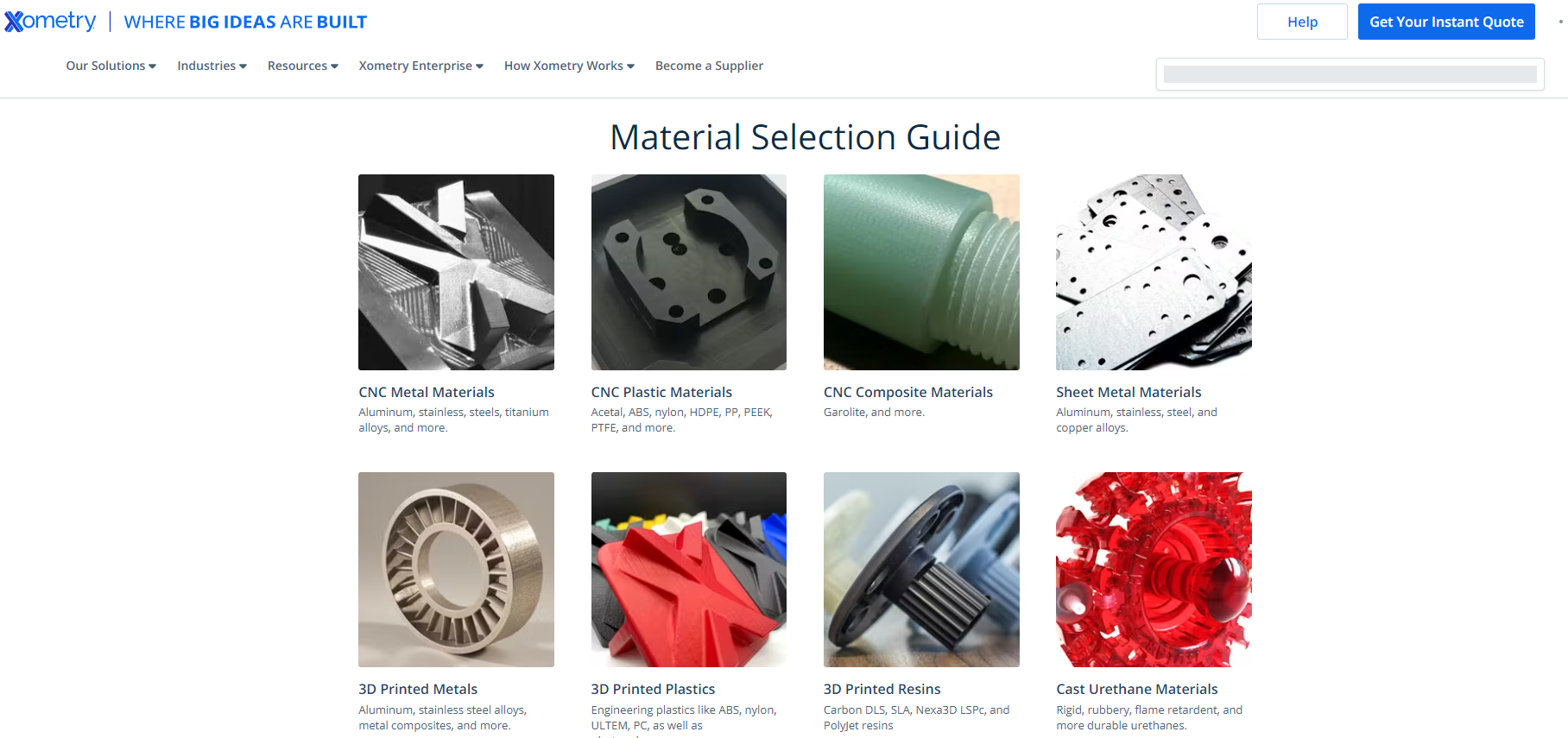

Evaluation of Xometry's Material Pages

Material Variety

Xometry boasts an extensive library of materials for CNC machining, encompassing a vast array of metals, plastics, composites, and even ceramics. The sheer number of options can be overwhelming for some users, but it ensures that Xometry can cater to diverse and specialized applications. Compared to Tuofa, Xometry's material variety is significantly broader, providing users with more choices.

Material Information

Xometry offers comprehensive material information, including properties, specifications, and applications. However, the presentation of this information can be somewhat dense and technical, potentially making it challenging for users without a strong engineering background to fully grasp the nuances of each material. Xometry also provides material data sheets for download, which can be helpful for in-depth analysis.

Search and Filter Options

Xometry's material page features robust search and filter options. Users can search for materials by name, category, or specific properties. The filter options allow users to narrow down their choices based on various criteria, such as material type, machinability, strength, and cost. These features make it convenient for users to quickly find materials that meet their exact requirements.

Comparison of CNC Machining Capabilities

Machine Types

Both Tuofa and Xometry possess a wide range of CNC machines, including 3-, 4-, and 5-axis milling machines, turning centers, and Swiss-type lathes. This enables them to handle a variety of machining operations, from simple 2D shapes to complex 3D geometries. However, without specific information on the exact machine models and capabilities of each company, it is challenging to make a direct comparison.

Minimum Order Quantities (MOQs)

Tuofa's minimum order quantity is typically one piece, making it suitable for prototyping and low-volume production runs. Xometry, on the other hand, focuses on high-volume production and may have higher MOQs depending on the specific project.

Additional Services

Both Tuofa and Xometry offer additional services that complement their CNC machining capabilities. Tuofa provides design assistance, prototyping, and various finishing options. Xometry offers instant quoting, design for manufacturability (DFM) analysis, and expedited production options.

Conclusion

In conclusion, both Tuofa and Xometry present valuable resources for users seeking information on CNC machining materials and capabilities. Tuofa's material page excels in providing in-depth information and showcasing its expertise in specific materials, while Xometry's extensive material library and advanced search and filter options cater to a wider range of applications.

When choosing between the two, users should consider their specific needs and priorities. If you require detailed material information and prefer a curated selection of materials, Tuofa might be a better choice. If you need a vast array of material options and advanced search capabilities, Xometry might be more suitable.

It's important to note that this evaluation focused primarily on the website content and did not include a practical assessment of each company's machining capabilities or customer service. It is recommended to request quotes and samples from both providers to make a fully informed decision.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Xometry vs Tuofa: Aluminum CNC Machining Showdown

Xometry vs Tuofa: Aluminum CNC Machining Showdown