Xometry vs Tuofa: Aluminum CNC Machining Showdown

Aug 09,2024

Aug 09,2024

Aluminum's high strength-to-weight ratio, excellent thermal conductivity, and ease of machining make it a preferred choice for diverse applications. However, achieving optimal results requires a CNC machining partner with the right expertise and technology. This article presents a comparative analysis of Tuofa and Xometry's aluminum CNC machining capabilities, focusing on key factors that influence part quality and production efficiency.

Key Factors in Choosing an Aluminum CNC Machining Partner

Before we embark on our comparative journey, let's outline the key factors that discerning customers consider when selecting an aluminum CNC machining provider:

- Machining Prowess: The types of CNC machines at their disposal, the tolerances they can achieve, and the surface finishes they offer are critical in determining the complexity and quality of parts they can produce.

- Alloy Adaptability: The range of aluminum alloys a provider works with is crucial to ensure your project's specific material requirements are met.

- Experience & Expertise: The provider's track record in aluminum CNC machining and industry-specific knowledge can significantly impact the success of your project.

- Timely Delivery & Production Scale: Lead times and the ability to handle varying order volumes are crucial, especially for time-sensitive projects.

- Quality Assurance: Stringent quality control measures guarantee that the final parts meet or exceed your specifications and expectations.

- Customer-Centric Support: Responsive and helpful customer service, including design assistance and consultation, can make a world of difference in your overall experience.

Tuofa: Precision in Aluminum CNC Machining

Machining Prowess

Tuofa boasts an impressive arsenal of CNC machines, including 3-axis, 4-axis, and 5-axis milling machines, CNC turning centers, and Swiss-type lathes. This diverse machine inventory empowers them to tackle a wide spectrum of aluminum CNC machining service, from simple 2D shapes to intricate 3D geometries. Their commitment to precision is evident in their ability to achieve tight tolerances and superior surface finishes, ensuring your parts meet the highest standards.

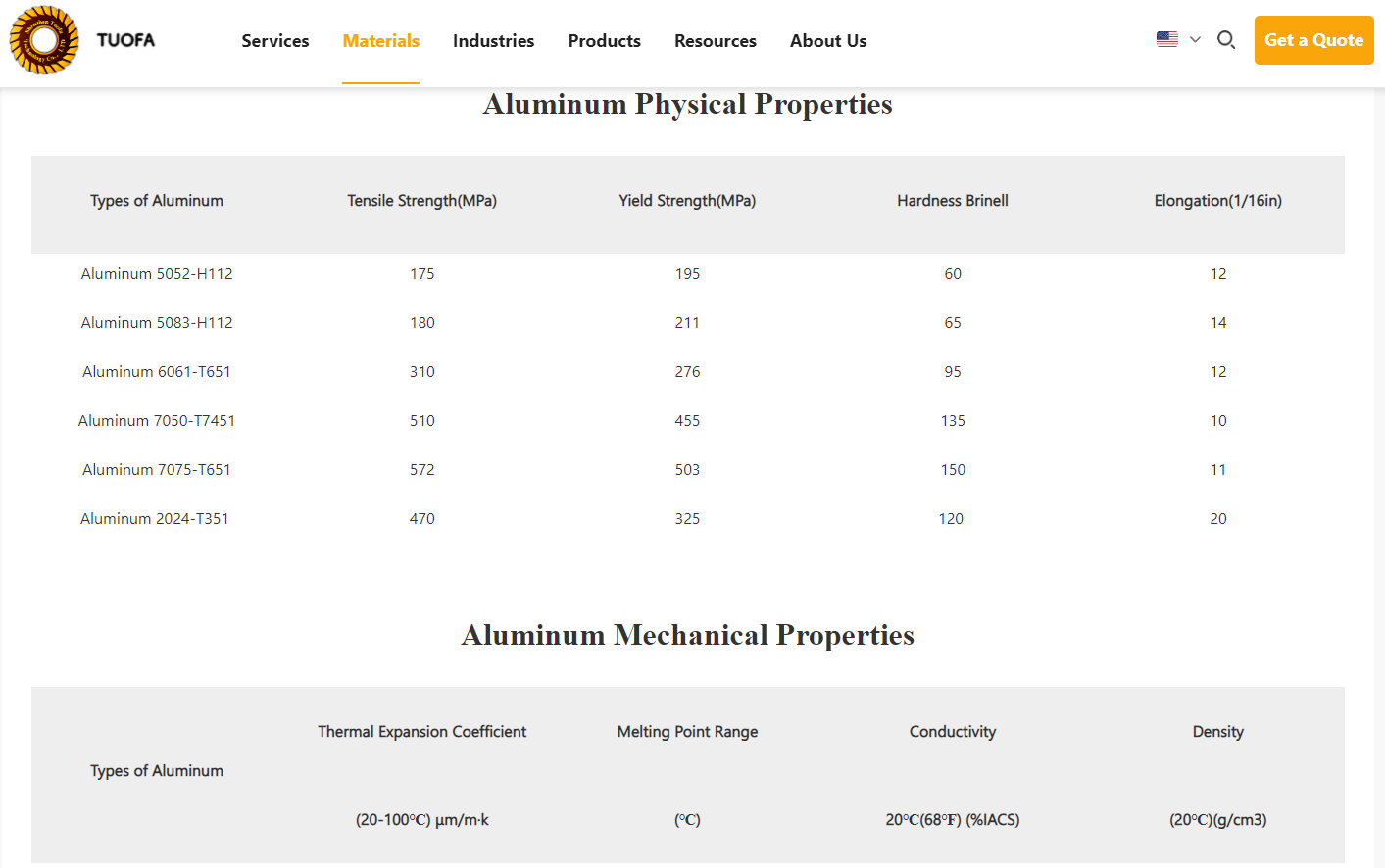

Alloy Adaptability

Tuofa demonstrates flexibility by working with various aluminum alloys, including popular series like 6061, 7075, and 2024, as well as other common grades. Moreover, they are open to working with customer-supplied materials, accommodating unique alloy requirements for specialized applications.

Experience & Expertise

With over a decade of experience in CNC machining, Tuofa has honed its skills and established itself as a trusted provider. Their website showcases their expertise across diverse industries, including automotive, aerospace, medical, and electronics. While they may not list specific certifications, their focus on quality and customer satisfaction shines through testimonials and case studies.

Timely Delivery & Production Scale

Tuofa understands the importance of timely delivery and strives to provide competitive lead times. Their typical turnaround times range from a few days to several weeks, depending on the project's complexity and order volume. They are equipped to handle both small-batch and large-volume production runs, offering the scalability to meet your evolving needs.

Quality Assurance

Tuofa's dedication to quality is unwavering. They implement stringent quality control measures throughout the production process, utilizing advanced inspection equipment and adhering to international quality standards. While they may not explicitly offer warranties, their customer-centric approach and focus on satisfaction speak volumes about their commitment to delivering high-quality parts.

Customer-Centric Support

Tuofa prioritizes clear communication and accessibility. Their website features a prominent "Get a Quote" button and provides multiple contact channels, including email, phone, and an online inquiry form. They go the extra mile by offering design assistance and consultation services, ensuring your designs are optimized for manufacturability and efficiency.

Xometry: Aluminum Machining on a Networked Scale

Machining Capabilities through Partnerships

Xometry harnesses the power of a vast network of manufacturing partners, granting them access to an extensive array of CNC machines and capabilities. Their website proudly highlights their ability to machine various aluminum alloys with tight tolerances and exceptional surface finishes. They also offer specialized processes like anodizing and powder coating, expanding the possibilities for your aluminum parts.

Extensive Alloy Selection

Xometry's platform boasts an impressive selection of aluminum alloys, encompassing both standard and specialty grades. Their user-friendly online interface allows you to effortlessly filter and select the ideal alloy for your project, ensuring compatibility and optimal performance.

Collective Expertise

Xometry's platform serves as a bridge, connecting you with a network of vetted manufacturing partners, each possessing unique expertise and experience in aluminum CNC machining. While individual partner qualifications may vary, the platform provides access to a vast pool of talent and capabilities, ensuring the perfect match for your project.

Instant Quotes & Scalable Production

Xometry's instant quoting system revolutionizes the quotation process, providing real-time pricing and lead time estimates. For those urgent projects, they offer expedited production options. Their network of partners enables them to handle both low-volume and high-volume orders, providing the scalability you need.

Quality Commitment

Xometry places a premium on quality assurance. They partner exclusively with ISO 9001:2015 certified manufacturers and implement rigorous inspection processes. Their quality guarantee provides an added layer of confidence, ensuring your parts meet the highest standards.

Digital-First Support

Xometry's platform is designed for user-friendliness and offers 24/7 online support. They also provide valuable design for manufacturability (DFM) feedback, helping you optimize your designs and avoid potential production pitfalls.

Head-to-Head: Tuofa vs Xometry

| Feature | Tuofa | Xometry |

|---|---|---|

| Machining Capabilities | Wide range of in-house CNC machines, tight tolerances, superior surface finishes | Access to diverse CNC machines and capabilities through a network of partners |

| Aluminum Alloys Offered | Various common aluminum alloys, flexibility to work with customer-supplied materials | Extensive selection of aluminum alloys, including specialty grades |

| Expertise and Experience | Over a decade of experience, focus on quality and customer satisfaction | Access to a network of vetted manufacturing partners with varying expertise |

| Lead Times and Production Capacity | Competitive lead times, ability to handle both small-batch and large-volume orders | Instant quoting, expedited production options, scalability through partner network |

| Quality Control | Stringent quality control measures, focus on customer satisfaction | ISO 9001:2015 certified partners, quality guarantee |

| Customer Service and Support | Multiple contact channels, design assistance, and consultation | 24/7 online support, DFM feedback |

Making the Right Choice

Both Tuofa and Xometry present compelling options for your aluminum CNC machining needs. Tuofa shines with its in-depth material expertise, personalized service, and focus on delivering high-quality parts. Xometry's strengths lie in its vast material selection, instant quoting, and ability to handle diverse project scales through its network of partners.

If you value expert guidance, meticulous attention to detail, and a strong emphasis on quality, Tuofa CNC Machining is an excellent choice. Their commitment to customer satisfaction and ability to handle both small and large orders make them a reliable partner for your aluminum machining projects.

Contact Tuofa today to discuss your aluminum CNC machining needs and experience the difference that precision and expertise can make!

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

3000 Series Aluminum Alloys: Comprehensive Guide

3000 Series Aluminum Alloys: Comprehensive Guide