What is CNC Milling? Types, Process and Operation

Dec 10,2024

Dec 10,2024

CNC milling is a cutting method which is a feature of Computer Numerical Controlled (CNC) Machine. It has been in use for the last two centuries. During the time of industrialization, it was the most used and advanced machining technique. Now it has become a very critical cutting. This article is all about CNC milling that will increase your knowledge and expertise. So, let’s start with its brief introduction:

What is CNC Milling?

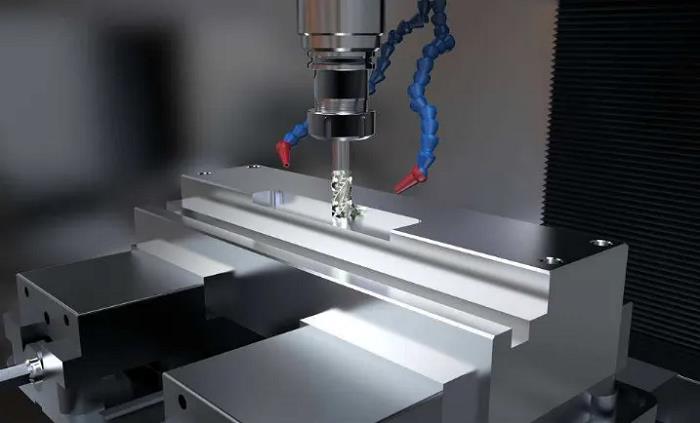

CNC milling is a machining technique for manufacturing complex parts in different industries. The cutting or removal of the excessive material results in desired shapes. Multiple rotaries cutting tools are used for the cutting process and they are controlled by a CNC program i.e. CAM (Computer-aided Manufacturing) software

Desktop CNC Milling Meaning

It means compact CNC milling machine, which is mainly used in small businesses, and educational institutes, to make prototypes and complex parts etc.

Is CNC Milling Easy?

Once you learn the CNC program, then it is easy to operate because of its automation features.

What is a CNC Milling Machine Used for

CNC Milling Machine is used in manufacturing industries to make complex parts such as airframe parts, landing gear, transmission cases, orthopaedic implants, heat sinks, missile guidance systems customized jewellery etc. All these parts require tight tolerance and precision which precision CNC milling provides.

How Does CNC Milling Work?

This section will address comprehensively the working of a CNC Milling process.

The Role of Computer Numeric Control (CNC)

The important features such as automation during the work are due to this Computer Numeric Control component. This component works using CNC programs such as CAM software. All the data like spindle speed, cutting rate, changing of the tools etc. is fed into this system.

CNC Milling Process

The Milling Process starts with the preparation of the 3D design by using CAD software. The machine cannot read a 3D design which is why it is converted into a readable format using CAM software. Let us provide you with a step-by-step guide on how a CNC machine works.

Step-by-Step Guide: How CNC Milling Works

- The first step you will do is to design a 3D image of the required part then converting into a readable format through CAM software.

- Select appropriate cutting tools

- Fix the workpiece firmly in the workpiece holder

- Feed the spindle speed, cutting rate, axis etc. in the software

- Turn on the machine and you can start the process.

During processing, you should use a coolant as well because cutting off material generates heat within the sample which can damage your workpiece.

CNC Milling Software

CNC Milling Software is used to convert the given 3D designs of the workpiece into readable instructions for the machine. Then through programming, the speed of tools, tool path optimization etc. is stored in the software which then controls the tools according to the instructions automatically during work.

Types of CNC Milling Machines

The main differentiative aspect of CNC machines is the number of axes. The following types are common:

Vertical Milling Machines

You will see by using a vertical milling machine, the rate of precision is high. The main reason for high precision is the ease of machining the workpiece because the direction of the spindle is perpendicular to the workpiece.

Horizontal Milling Machines

If your workpiece is longer or heavier then this version of the milling machine is very useful. Although it is a bit older version it is best for machining longer or heavier parts. You will not see a major difference in the working procedure. You can see the horizontal milling machine in the following image.

5-Axis CNC Milling Machines

This machine is made for the manufacturing of complex designed parts with high precision. The parts such as aircraft parts which have very high safety standards are produced through this version of the machine. The cutting tools can machine the parts in the 5-axis so the production rate is high as well.

Universal and Turret Milling Machines

- Universal milling machine the moving cutting tool makes a complex design of the stationary workpiece.

- The workpiece is prepared through a stationary cutting tool.

Key Components of a CNC Milling Machine

The following components are the key components of a CNC milling machine:

CNC Control Panel

This part has keys on it as you can see in the image. These keys control the machine for instance, that red button is used to stop the machine in an emergency.

Spindle

The spindle contains those cutting tools which cut the material from the workpiece.

Tool Holders and Automatic Tool Changers (ATC)

Tool holders as the name itself tells, they hold different types of cutting tools.

These are two different components of a CNC milling machine with different functions. Tool holders hold the cutting tools and automatic tool changer (ATC) helps in changing the cutting tools automatically.

Workholding Systems

These systems are involved in holding the workpiece firmly and maintaining accuracy.

CNC Milling Machine Operation

Here, you will read about some important milling operations:

Face Milling

This process is used for the machining of flat workpieces, pockets etc. You will get a fine surface finish and tight tolerance. Its working is the same as of vertical CNC milling.

Plain Milling

The overall procedure of working is the same as of face milling. The only difference is the movement of the cutting tool which is parallel to the workpiece. To get the best results, your workpieces should be flat surfaces.

Angular Milling

In this operation, the spindle is perpendicular to the workpiece, but a cutting tool is placed at an angle to the workpiece. If you intend to make complex shapes, angled surfaces, grooves etc. you need to perform an angular milling operation.

Form Milling

It comes up with one limitation that is it is not a good choice for low-level production. It is a specialized type of CNC milling process which is used to make advanced and contoured shapes on the workpieces by using rotating tools.

End Milling

It is a versatile milling process used to machine slots, shoulders, die cavities etc. The one main limitation is, that end mills are very expensive.

Benefits of CNC Milling

Some of the key advantages are given below:

- It is a cost-effective manufacturing method because there is no need to hire many people to operate the CNC milling machine.

- CNC milling is a reliable tool for preparing complex parts without any risks of errors due to the automation feature. Precision CNC milling and customized tool path optimization are the important features to make critical parts i.e. turbine blades

- Since you will not physically remain in contact with the workpiece machining, that is why they are very low chance that you will suffer any injury.

- A CNC milling machine can operate 24/7 continuously because of the CNC program. Automatic Tool Changing (ATC) is another feature behind this advantage.

- Daily cleaning and inspection are enough to keep the CNC milling machine working. It does not need maintenance a lot.

- 5-Axis CNC milling machine is the most advanced version of milling machines and is used for intricate complex parts.

Materials of CNC Milling Machining

A CNC machine has the freedom to work with any material, it can machine composites, metals, plastics etc. with excellent accuracy.

Metals CNC Milling

The metals which are tough and machinable such as Aluminium, low carbon steel, stainless steel, Copper, titanium etc. are very easy to machine on a CNC machine. Because during work, the CNC machine puts force on the workpieces due to which hard and brittle metals like high carbon steel, and martensitic steel can fracture, that’s why only tough and ductile materials should be chosen for better results.

Plastics CNC Milling

For CNC milling operations, those plastics are suitable and have suitable strength for machining. Plastics like polyvinyl chloride, Polyether ether Ketone etc. are thermosetting plastics and have suitable strength for machining and are commonly used in industries to make bearings and piston parts.

CNC Milling vs CNC Turning

The primary difference between milling and turning is the shape of the workpiece. Further differences are given in the table:

Key Differences Between Milling and Turning

|

CNC Milling |

CNC Turning |

|

The running cutting tool removes material over the stationary workpiece. |

The workpiece is brought to the stationary cutting tool. The cutting tool cuts the material by rotating. |

|

Plain milling, face milling etc. are different types of CNC milling. |

Knurling, taper turning, drilling etc. are CNC turning operations. |

|

It is a versatile operation because of the freedom of materials. Any material like composites, wood etc. can be machined through CNC milling. |

It is very difficult to machine composite materials on CNC turning. |

Which Process is Better for Specific Applications?

Customized parts, gears and helical shapes, flat surfaces, pockets and edges, slots and keyways etc. are commonly prepared through CNC milling operation.

For cylindrical components, tapered surfaces, grooved parts, flanged parts etc. must be machined by turning operation.

Applications of Custom CNC Milling Services

You know that the CNC milling machine is very versatile and works automatically, that’s why it is used in many important industries where the precision of the products is the primary preference.

Aerospace Industry

We know that there are very high standards of safety in the aerospace industry because a huge investment of money and humans are directly involved. For the maximum protection of lives and money, very high precision and tight tolerance are required. To meet aerospace standards, parts such as landing gears, bulkheads, aircraft frames etc. are manufactured through a CNC milling machine.

Automotive Industry

The Automotive industry is also related to the safety of lives, that’s why it requires very carefully machined components. The parts which are prepared through CNC milling are body panels, frame members, engine blocks etc.

Medical and Healthcare Applications

The reliability of the things used in the medical or health sector is very important. That’s why forceps and retractors used in surgery, orthopaedics etc. are manufactured through the CNC milling process.

Consumer Goods Manufacturing

Now it’s common to use a CNC milling machine in the electronics industry, jewellery etc. due to the advancements i.e. 5 axes CNC milling machine.

How Much Does CNC Milling Cost?

The range of 20$-60$ is the price but ultimately it depends on the complexity of the design and the material of course.

Factors Affecting CNC Milling Costs

If you are going to buy CNC milling-prepared parts, you should know these factors which affect the costs.

Material and Part Complexity

If you have brittle material, then the milling price will be high because brittle materials are very difficult to machine. Brittle materials break catastrophically so the operators must work very carefully keeping the integrity of the structure.

The same is the case with the complexity of design, the higher care, time and energy result in higher costs.

Production Volume and Lead Time

if you choose any machine and it yields a higher volume in shorter times than other versions, your machine is perfect. To make this relation better, a CNC machine will be a good option.

How to Estimate CNC Milling Costs

As we discussed earlier, the complexity of the design and the material of the workpiece are the main factors behind the prices. So, you should have sufficient knowledge of these factors before making a budget etc.

Choose Tuofa's Custom CNC Machining Services

If you are affiliated with a critical industry let’s say it is aerospace and you need the best machinists to prepare the best-precision parts, you can come to Toufa Custom CNC Machining Services. We have the most advanced machines and skilled operators to manufacture the parts at the best prices.

Frequently Asked Questions (FAQs)

Is CNC Milling Suitable for Low-Volume Production?

Yes, it is suitable for low-volume production because of the variety of versions and prices of milling machines.

How Accurate is CNC Milling?

It is controlled by a CNC program which makes it a very reliable and accurate tool for producing tight tolerance parts i.e. engine blocks, turbine blades etc.

What Are the Limitations of CNC Milling?

One of the limitations of CNC milling is that, you will need large amounts of investment to buy these advanced machines.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Custom CNC Machining Industrial Pneumatic Tools Parts

Custom CNC Machining Industrial Pneumatic Tools Parts