What are Uses of Aluminium? Everything You Should Know

Jul 16,2024

Jul 16,2024

Aluminium is a silvery-white, soft, non-magnetic, and ductile metal. Aluminum CNC Machining is crucial in producing precise components. Cutting aluminium parts is essential in many manufacturing processes. It is widely used in various industries due to its unique properties. Its versatility is notable. Combined with its lightweight and strength, aluminium becomes an essential material. It plays a crucial role in modern manufacturing. In this article, we'll explore the key properties of aluminium. We will also discuss its common uses. Additionally, we will examine why it is the preferred material for many applications.

Brief Overview of Aluminium

Aluminium (Al) is the third most abundant element in the Earth's crust, constituting about 8% by weight. It was first isolated in the 19th century and has since become one of the most important metals in the industry. Aluminium's ability to form alloys with other metals enhances its properties. This makes it suitable for a wide range of applications.

Aluminum Composition

Aluminum, symbol Al and atomic number 13, is known for its lightweight, strength, and versatility. Its composition and alloying elements significantly enhance its properties for various applications.

|

Series |

Primary Alloying Elements |

Composition |

|

1000 |

Pure Aluminum |

99% or higher Al |

|

2000 |

Copper |

2-10% Cu |

|

3000 |

Manganese |

Up to 1.5% Mn |

|

4000 |

Silicon |

4-12% Si |

|

5000 |

Magnesium |

0.2-6% Mg |

|

6000 |

Magnesium and Silicon |

0.4-1.5% Mg, 0.4-1.2% Si |

|

7000 |

Zinc |

1-8% Zn, often combined with Mg and Cu |

|

8000 |

Miscellaneous Elements |

Varies widely |

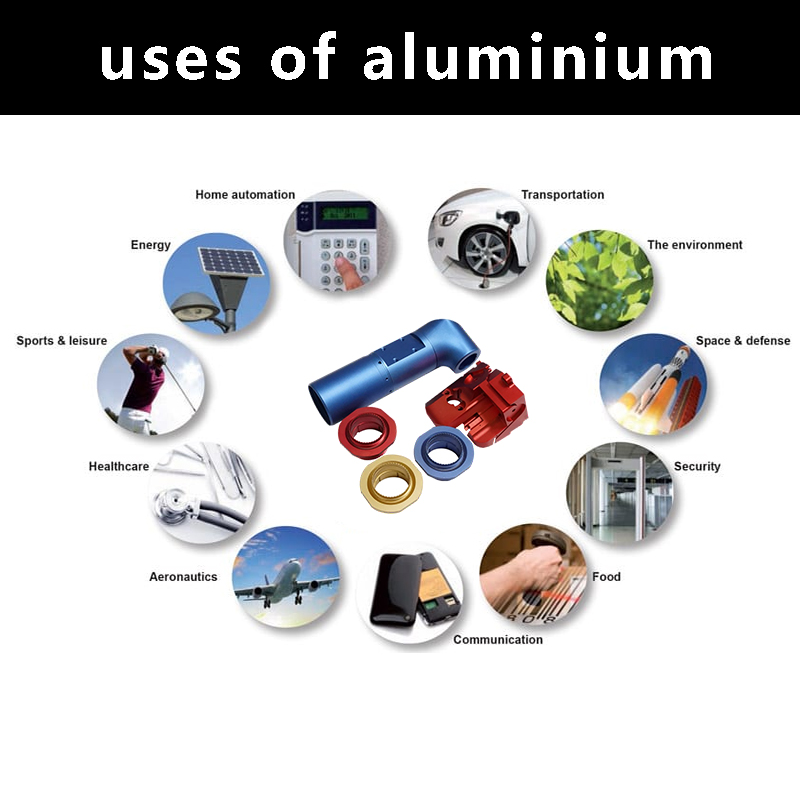

Importance in Various Industries

Aluminium's significance in industries such as aerospace cannot be overstated. Its importance in the automotive industry is also crucial. In construction, aluminium plays a vital role. Similarly, its impact on electronics is immense. Its unique combination of properties is remarkable. This allows for innovative applications. These applications contribute to technological advancements and economic growth.

Why Aluminium is a Preferred Material

Aluminium is preferred over other materials for several reasons. It is lightweight and has a high strength-to-weight ratio. It also offers corrosion resistance and excellent thermal and electrical conductivity. Additionally, aluminium is highly recyclable. These characteristics make it indispensable in sectors demanding high performance and sustainability.https://www.tuofa-cncmachining.com/

Key Properties of Aluminium

Aluminium, with its unique set of properties, is a highly versatile and widely used metal. Below is a detailed table outlining the key properties of aluminium and their benefits in various applications.

|

Property |

Description |

|

Lightweight |

About one-third the weight of steel, reduces overall weight, enhances fuel efficiency and performance. |

|

Corrosion Resistance |

Forms a protective oxide coating, highly resistant to corrosion, suitable for harsh environments. |

|

Electrical Conductivity |

Excellent conductor of electricity, used in electrical transmission lines and other applications. |

|

Thermal Conductivity |

High thermal conductivity, efficiently dissipates heat, used in heat exchangers and cooling systems. |

|

Ductility |

Highly ductile, easily formed into various shapes and sizes through rolling, extruding, and drawing. |

|

Recyclability |

100% recyclable without losing properties, recycling requires only 5% of the energy needed for new aluminium. |

|

Non-Magnetic |

Suitable for electronic devices and applications where magnetic interference is a concern. |

|

Reflectivity |

High reflectivity, ideal for applications requiring reflective surfaces such as light fixtures. |

What is Aluminium Best Used For?

Aluminium's versatility makes it suitable for a broad range of applications. From aerospace to consumer electronics, aluminium's properties enable efficient solutions. They also allow for innovative applications. These benefits span across various industries. Its recyclability further underscores its importance in sustainable development.

Aerospace Industry

Aluminium's high strength-to-weight ratio makes it indispensable in the aerospace industry. Its resistance to corrosion is also crucial. Aluminium is used in aircraft structures, engines, and components. These applications ensure performance and safety.

Automotive Industry

In the automotive sector, aluminium is used to manufacture lightweight and efficient vehicles. Aluminium is used in engine components, body panels, and wheels. This reduces weight. As a result, it enhances fuel efficiency and performance.

Construction Industry

Aluminium is extensively used in construction for its durability, strength, and aesthetic appeal. Aluminium is used in windows, doors, facades, and roofing materials. These applications contribute to modern architectural designs.

Electrical Industry

Aluminium has excellent electrical conductivity. This makes it ideal for power transmission lines. It is also suitable for electrical wiring and components. It is also used in electronics for heat sinks and casings.

Packaging Industry

Aluminium is a popular material in the packaging industry. It is used for food packaging. It is also used for beverages and pharmaceuticals. It is lightweight and recyclable. Its barrier properties make it an excellent choice. These qualities contribute to sustainable packaging solutions.

Electronics Industry

In electronics, aluminium is used for casings. It is also used for heat sinks. Additionally, aluminium is found in components of devices. These devices include smartphones, laptops, and tablets. Its properties ensure efficient thermal management and durability.

Marine Industry

Aluminium's resistance to corrosion makes it suitable for marine applications. This includes shipbuilding. It is also used in offshore structures. It ensures the longevity and performance of vessels in harsh marine environments.

Advanced Uses of Aluminium

Advanced uses of aluminum include aerospace, automotive, and construction. It is also used in electronics, packaging, and marine applications. Additionally, aluminum is important in energy, consumer goods, railway, and medical equipment. Its lightweight nature is valuable in these fields. Its high strength is also important. Additionally, its corrosion resistance adds to its value.

Solar Panels

Aluminium is used in solar panel frames and mounting systems. This is due to its strength, lightweight nature, and corrosion resistance. It helps in the efficient installation and long-term durability of solar energy systems.

Wind Turbines

In wind turbines, aluminium is used for components such as blades and nacelles. Its lightweight nature contributes to the efficiency of wind energy systems. Additionally, its strength enhances their reliability.

Battery Technology

Aluminium is being explored in advanced battery technologies for energy storage solutions. Aluminium has the potential to improve battery performance. It can also help reduce costs. These qualities make it a key material in renewable energy storage.

Medical Devices

Aluminium is used in medical devices for its lightweight, strength, and biocompatibility. It is found in surgical instruments, medical equipment, and mobility aids.

Prosthetics

Aluminium is used in prosthetics to provide lightweight and durable solutions for patients. Its properties ensure comfort and functionality in prosthetic devices.

Packaging for Pharmaceuticals

Aluminium is used in pharmaceutical packaging. It protects medications from light, moisture, and contamination. Its barrier properties ensure the safety and efficacy of pharmaceutical products.

Frequently Asked Questions

Common problems with aluminum cover many aspects. Here are two common problems.

Which Side of Aluminium Foil to Use?

When using aluminium foil, the difference between the shiny and dull sides is minimal. The shiny side reflects heat better, while the dull side absorbs it. For cooking, either side can be used interchangeably. However, some prefer the shiny side. They believe it offers better heat reflection.

Can I Use Aluminium Foil Instead of Baking Paper?

Aluminium foil can be used instead of baking paper for certain applications. However, baking paper is non-stick and heat-resistant, making it more suitable for baking. Aluminium foil is better for grilling and broiling. However, it may require oil to prevent sticking.

Conclusion

The uses of aluminium span across various industries due to its exceptional properties. Tuofa Factory in China is a key player in aluminum manufacturing. It is integral in aerospace, automotive, and construction. Aluminum is also crucial in electronics and packaging. This is due to its lightweight nature, strength, and corrosion resistance. Aluminium's recyclability also makes it a sustainable choice. Click here to get a free quote.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Advantages and Disadvantages of Aluminium: Is It Right for Your Project?

Advantages and Disadvantages of Aluminium: Is It Right for Your Project?