Advantages and Disadvantages of Aluminium: Is It Right for Your Project?

Jul 16,2024

Jul 16,2024

Aluminium is a versatile material used in a wide range of industries due to its unique properties. Understanding the advantages and disadvantages of aluminium is crucial for professionals in the manufacturing and mechanical design sectors. This knowledge helps them make informed decisions. https://www.tuofa-cncmachining.com/

Properties of Aluminium

Aluminum properties include being lightweight and corrosion-resistant. It has high conductivity and is malleable and ductile. Aluminum is non-magnetic and has high reflectivity. It is also recyclable and has a low density. Cutting aluminium parts is a good thermal conductor, non-toxic, and durable.

Lightweight

Aluminium is renowned for its low density, contributing to its lightweight nature. This property is particularly beneficial in the transportation and aerospace industries. Reducing weight is crucial for enhancing fuel efficiency and performance. The lightweight nature of aluminum makes it an ideal choice for automotive components. It is also perfect for aircraft structures and even bicycle frames.

Corrosion Resistance

One of aluminium's standout features is its natural corrosion resistance. The formation of a protective oxide layer on its surface prevents further oxidation. This ensures durability in harsh environments. This property significantly reduces maintenance costs. It also extends the lifespan of products exposed to corrosive elements, such as marine environments and outdoor applications.

High Strength-to-Weight Ratio

Aluminium boasts a high strength-to-weight ratio. This makes it a preferred material for structural components. When compared to other metals like steel, aluminium offers comparable strength while being much lighter. This makes it an excellent choice for applications in bridges and high-rise buildings. It is also ideal for various structural elements where weight reduction without compromising strength is essential.

Electrical and Thermal Conductivity

Aluminium is an excellent conductor of electricity and heat. Its efficient electrical conductivity makes it suitable for electrical applications, including power transmission lines and electronic components. Additionally, its thermal conductivity makes it ideal for use in heat exchangers. Aluminium is also used in car radiators and HVAC systems. In these applications, efficient heat transfer is critical.

Malleability and Ductility

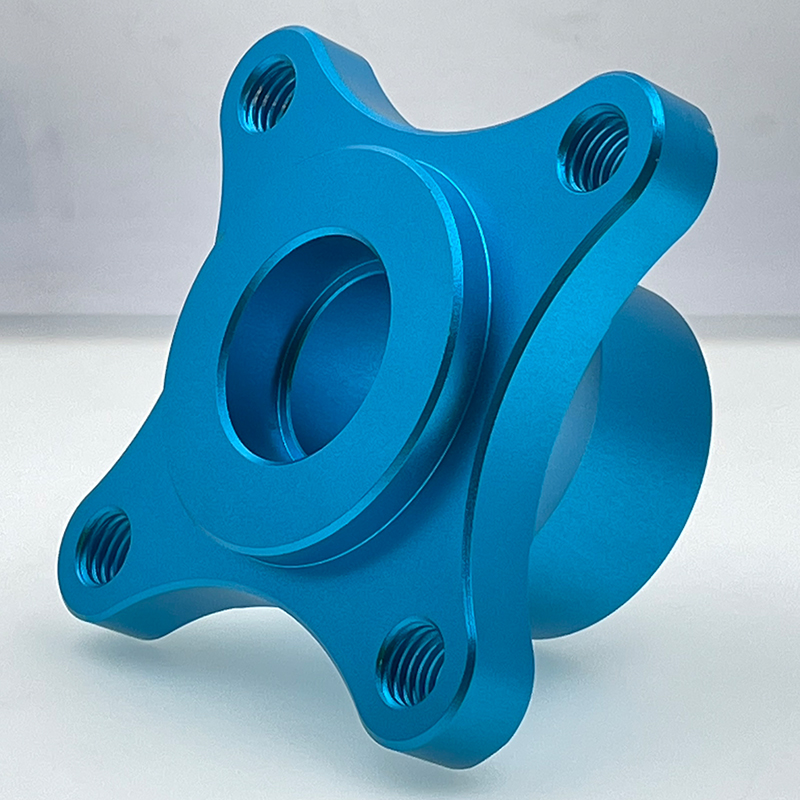

The malleability and ductility of aluminum allow it to be easily formed and machined into various shapes and designs. This flexibility in manufacturing processes facilitates the creation of intricate and complex components. It makes aluminum a popular choice in industries requiring custom parts and prototypes.

Recyclability

Aluminum is highly recyclable. A significant portion of produced aluminum comes from recycled sources. The recycling process of aluminum consumes only a fraction of the energy required to produce new aluminum. This results in substantial energy savings and reduced environmental impact. This sustainability aspect makes aluminium an eco-friendly choice for various applications.

Non-Magnetic and Reflective Properties

Aluminum's non-magnetic nature makes it suitable for use in electronic devices. It is also ideal for applications requiring electromagnetic shielding. Additionally, its reflective properties are beneficial for creating reflective surfaces and decorative elements. These characteristics make aluminium a versatile material in electronics, lighting, and design.

Cost-Effectiveness and Versatility

Aluminium is cost-effective and versatile, finding applications across a wide range of industries. From packaging materials to aerospace components, aluminum's affordability and adaptability make it an attractive option. It is ideal for manufacturers and designers seeking a balance between cost and performance.

Durability and Non-Toxicity

Aluminium is durable and non-toxic, making it safe for use in food and beverage packaging. Its resistance to corrosion and non-reactive nature ensure the integrity and safety of packaged goods. Aluminum is also widely used in the medical and pharmaceutical industries. In these industries, hygiene and safety are paramount.

Aesthetic Appeal

Aluminum's attractive finish and adaptability to various designs make it popular in consumer products and architecture. Its sleek appearance and ability to be anodized or coated in different colors enhance its aesthetic appeal. This makes it a preferred material for modern and stylish designs.

Disadvantages of Aluminium

Disadvantages of aluminum include low strength and susceptibility to corrosion. It is prone to fatigue and has poor high-temperature performance. Aluminum is difficult to weld and has a high cost. It is also prone to easy deformation and surface scratches. Additionally, it has poor conductivity and low hardness.

Lower Tensile Strength

While aluminium has a high strength-to-weight ratio, its tensile strength is lower compared to steel. This limitation makes aluminium less suitable for heavy load-bearing applications. Maximum strength is required in these cases. Engineers and designers must consider this factor when selecting materials for structural components.

Cost Factors

Aluminium's initial costs can be higher compared to some other materials like steel. However, these costs are often offset by the material's long-term benefits. These benefits include reduced maintenance, energy savings, and recyclability. It's essential to weigh the upfront costs against the overall lifecycle benefits. This is important when evaluating aluminium for specific applications.

Fabrication and Joining Challenges

Welding and joining aluminium can be challenging due to its high thermal conductivity. It also tends to form brittle intermetallic compounds. Advances in aluminium processing, such as friction stir welding and adhesive bonding techniques, are helping to overcome these challenges. These advancements improve the reliability of aluminium joints.

Performance in Extreme Conditions

Aluminium's performance in extreme temperatures can be a limiting factor. In high-temperature environments, aluminium can lose strength. In extremely low temperatures, it can become brittle. These limitations must be considered when designing components. This is especially important for applications with significant temperature fluctuations.

Aluminium vs. Other Materials

Choosing the right material depends on the specific requirements of your application. Aluminium's lightweight, excellent corrosion resistance, and recyclability make it versatile. Steel's strength offers unique advantages. Copper's conductivity provides significant benefits. Plastics' design flexibility is another unique advantage.

Aluminium vs. Steel

When comparing aluminium and steel, weight, strength, and corrosion resistance are key factors. Aluminium is lighter and more corrosion-resistant. This makes it suitable for applications where weight and environmental exposure are concerns. Steel, on the other hand, offers higher tensile strength. It is often preferred for heavy-duty applications.

|

Property |

Aluminium |

Steel |

|

Density |

2.7 g/cm³ |

7.85 g/cm³ |

|

Tensile Strength |

70-700 MPa |

370-1860 MPa |

|

Corrosion Resistance |

Excellent |

Poor to moderate (requires coating) |

Aluminium vs. Copper

Aluminium and copper are both excellent conductors of electricity. However, aluminium is lighter and less expensive. Copper's higher conductivity makes it the preferred choice for electrical wiring. It is also preferred for certain electronic applications. Aluminium is used in power transmission lines and components. This is because weight and cost are critical factors.

|

Property |

Aluminium |

Copper |

|

Density |

2.7 g/cm³ |

8.96 g/cm³ |

|

Electrical Conductivity |

37.7 x 10⁶ S/m |

58 x 10⁶ S/m |

|

Cost (per kg) |

$2.40 |

$9.00 |

Aluminium vs. Plastics

Aluminium and plastics each have distinct advantages. Aluminium offers superior structural strength and is highly recyclable, making it environmentally friendly. Plastics, however, are lighter. They can be molded into complex shapes. This makes them suitable for specific applications where weight and design flexibility are priorities.

|

Property |

Aluminium |

Plastics |

|

Density |

2.7 g/cm³ |

0.9-2.2 g/cm³ |

|

Tensile Strength |

70-700 MPa |

20-100 MPa |

|

Recyclability |

Highly recyclable |

Varies; some types are recyclable |

|

Moldability |

Moderate |

Excellent |

Applications of Aluminium

Applications of aluminum include aerospace components and automotive parts. It is also used in packaging and construction materials. Other uses include electrical wiring and heat exchangers. Aluminum is found in kitchen utensils and consumer electronics. It is also used in marine equipment and sports equipment.

Automotive Industry

In the automotive industry, aluminium plays a crucial role in reducing vehicle weight. This leads to improved fuel efficiency and performance. Aluminium is used in car bodies, engine components, radiators, and wheels. It contributes to the overall sustainability and efficiency of modern vehicles.

Aerospace Industry

Aluminium's importance in the aerospace industry cannot be overstated. Its lightweight and high-strength properties make it ideal for aircraft construction. These properties enhance flight performance and fuel economy. Aluminium is used in fuselage panels, wings, and other critical aircraft components.

Construction Industry

In the construction industry, aluminium is used for structural elements in buildings and infrastructure projects. Its long lifespan is an attractive feature. The low maintenance requirements make it a preferred choice for architects and engineers. Aluminium's versatility also allows for creative and aesthetically pleasing architectural designs.

Electronics and Electrical Industry

Aluminium is widely used in the electronics and electrical industry due to its excellent conductivity and heat dissipation properties. It is found in consumer electronics. It is also used in power lines and components where efficient performance and reliability are essential.

Packaging Industry

The packaging industry benefits from aluminium's properties, particularly in food and beverage packaging. Aluminium is lightweight, durable, and non-toxic, ensuring the safety and preservation of packaged products. Its recyclability also contributes to the industry's sustainability efforts.

Benefits of Recycling Aluminium

Benefits of recycling aluminum include energy savings and reduced greenhouse emissions. It also helps in the conservation of natural resources and cost efficiency. Recycling aluminum decreases landfill waste and lowers production costs. Additionally, it contributes to the preservation of ecosystem health.

Energy Savings

Recycling aluminium saves up to 95% of the energy required to produce new aluminium from raw materials. This significant energy saving translates to reduced greenhouse gas emissions. It also results in a lower carbon footprint. These benefits contribute to environmental conservation.

Economic Benefits

Recycling aluminium offers economic benefits, including cost savings and economic incentives. The recycling process generates revenue and supports jobs in the recycling industry. It contributes to a circular economy and promotes sustainable growth.

Resource Conservation

Recycling aluminium helps conserve natural resources by reducing the need for mining and refining new aluminium. This preservation of raw materials minimizes environmental impact. It also supports sustainable resource management practices.

Conclusion

Aluminium offers numerous advantages, including lightweight properties, corrosion resistance, a high strength-to-weight ratio, and recyclability. These qualities make it a versatile material in various industries. However, it also has disadvantages. These include lower tensile strength and challenges in fabrication. By understanding these pros and cons, professionals can make informed decisions about Aluminum CNC Machining in their projects. Tuofa Manufacturer in China, It is committed to providing high-quality aluminium machining services. We leverage our expertise to meet the diverse needs of our clients. As the industry continues to evolve, the future of aluminium looks promising. Ongoing innovations are enhancing its applications and sustainability.Click here to get a free quote.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Black Anodized Aluminum: Your Ultimate Guide to a Superior Finish

Black Anodized Aluminum: Your Ultimate Guide to a Superior Finish