What Is Swiss Turning? A Complete Guide

Feb 08,2025

Feb 08,2025

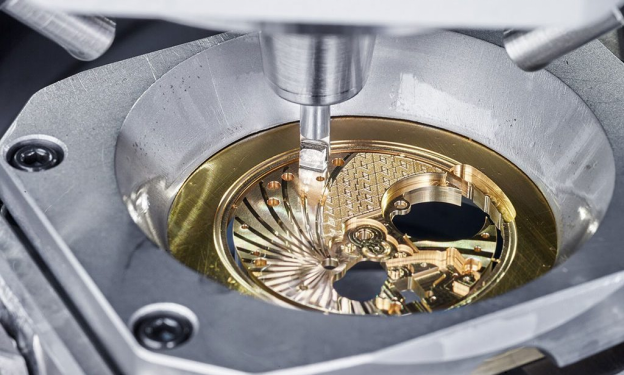

Swiss turning originated in Switzerland. Previously it was used for watchmaking industries. You know about the size of the components of a watch, which are very small. So, Swiss turning was originally designed for the machining of smaller components. Except for the watchmaking industry, smaller components are used in every industry like in aerospace, electronics etc. This is an interesting article which covers comprehensive information related to Swiss turning, its benefits, types etc. So, let's start.

What is a Swiss Lathe?

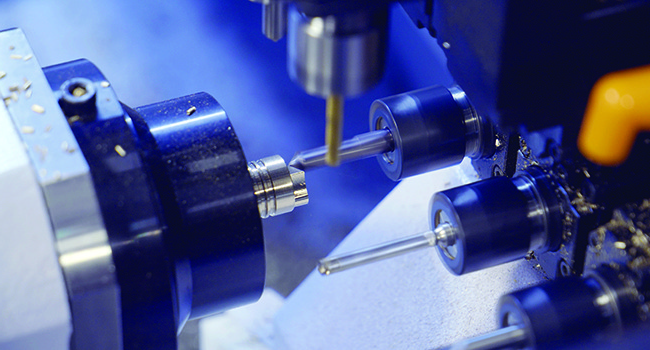

Swiss lathe has multiple names, you can call it a Swiss-type lathe or a Swiss screw machine. The Swiss-lathe machine is used to machine small, intricate parts. This machine is equipped with multiple tools, so multiple operations can be performed simultaneously. This machine is a part of the Computer Numerical Controlled (CNC), which is different from conventional lathe machines. It is used to produce small, precision intricate parts.

Understanding the Swiss Turning Process

The working process of the Swiss turning process is opposite to conventional lathe machines, but the concept is the same. In this machine, the workpiece is placed in a guide bushing and moves axially but the cutting tools remain stationary. In a single setup, you can perform multiple operations including milling and threading along with turning.

What is a Swiss Turning Capability?

A Swiss machine is capable of many important features such as tight tolerances, precision etc. These features are significant for a component's durability and resistance to failures. If the dimensions of a workpiece perfectly match the required design and its surface finish is excellent, then the outcome will be a reduction in costs and material waste.

The Role of Precision in Swiss CNC Machines

Precision is a way to the successful application of a component in any field. Highly precise parts prevent failures, human injuries and economic loss.

Why Swiss Machining Reduces Material Waste

The precision of any part or component is related to its stability during the machining process. If a workpiece vibrates during the cutting process, it results in dimensional errors and sometimes in cutting tool breakage. But in the case of Swiss CNC machines, you do not need to worry about precision issues. A component of the Swiss CNC machine, guide bushing, supports the stability of the workpiece closer to the cutting tools. This stability reduces material waste and tool deflection.

The History and Evolution of Swiss Lathes

Let's discuss the history of Swiss lathes in a little more detail:

Origins of Swiss Lathes in Watchmaking

In the 19th century, the watchmaking industries were common in Switzerland. The traditional Swiss machines are not so helpful in terms of the accuracy and durability of the components. To tackle the issue of dimensional accuracy, Swiss engineers designed a new Swiss lathe machine, equipped with guide bushing to support the stability of the workpiece during working.

From Manual to CNC Swiss Lathes

In the mid-20th century, CNC Swiss lathes were designed. Earlier Swiss lathes were manual, required more skilled operators and production was slower. Then the automation feature of the CNC Swiss lathe machine was introduced.

The Development of Swiss Type Machines

The development of the Swiss-type machines is related to the different industries and requirements. These machines are different due to features such as live-tooling, automatic bar feeders etc.

Benefits of Using Swiss-Type Lathes

Following are some important benefits of using Swiss Lathes:

Precision and Accuracy

The design of the machine includes guide bushing and sliding headstock. These parts of a Swiss machine make sure the part remains 100% stable during machining, enhancing precision and accuracy.

Reduced Cycle Time and Increased Efficiency

When the workpiece is stable, such as not vibrating, you will not need to machine it again and again, resulting in reduced cycle time and increased efficiency.

Superior Surface Finish and Tolerances

Superior surface finish and tolerances are important for the durability of a component. We can achieve superior surface-related properties through Swiss machining.

How Swiss CNC Machines Improve Productivity

You know that a Swiss CNC machine is equipped with multiple cutting tools, so it is easier to perform multiple operations such as drilling, milling etc. simultaneously. These simultaneous operations increase production rates and improve productivity.

Cost Benefits of Swiss Machining in Mass Production

If there is no need for post-turning operations, then obviously the production costs of components will be lower. In mass production, Swiss CNC turning makes sure that parts require minimum post-turning machining, that is it is cost-effective.

Swiss CNC Turning Limitations

Now, you should understand some limitations of a Swiss CNC turning:

High Initial Setup Costs of Swiss CNC Machines

Swiss CNC machines are fully advanced machines, equipped with many features. These features make them expensive equipment. Secondly, installation costs are higher.

Material Limitations in Swiss-Type Machining

Swiss-type machining is a versatile tool you can machine many materials including composites; polymers etc. still there is a limit to the choice of materials. Very hard and brittle materials like high-carbon steel are different to machines. These materials cause tool wear and a reduction in workpiece reliability.

What Materials Can Be Used in Swiss CNC Machining?

As we mentioned earlier, Swiss CNC machining applies to many materials, but the common materials include:

- In Metals: Al, Brass, Stainless steel, Ti, Cu

- Plastics: Delrin, Peek, Nylon

- Composites: Carbon fibre and fibreglass

Complexities of Swiss CNC Machine Operations

It is a complex machine in terms of operation and maintenance because this machine is fully advanced and works through CNC programming. This machine requires highly skilled operators.

Swiss Turning vs. Conventional Turning

Previously we just mentioned convention turning, now you will learn the difference in a little more depth.

What Is the Difference Between a Swiss Lathe and a Regular Lathe?

The major difference is the design of the machines and their functionality.

- Swiss Lathe

- Consists of a guide bushing which supports a workpiece close to the cutting tool

- This stability in the design makes the machining of small, intricate components easier and flawless

- Reduced tool deflection and dimensional errors

- Used in watchmaking, electronics industry commonly

- Conventional Lathe

- Chuck holds the workpiece, rotates along with moving the cutting tool

- Stability is difficult in the case of long, thin parts

- Manual and easy to use

- Used in threading, facing etc.

How Swiss CNC Machining Offers Higher Precision

A Swiss CNC machine is equipped with a lot of advanced features which include a bushing guide, high-resolution encoders and control systems. It offers higher precision because of:

- The bushing guide provides exceptional stability for the workpiece

- Multiple-axis capabilities allow for intricate cuts and tight tolerances

Benefits of Swiss Turning vs. Conventional Turning

|

Swiss Turning |

Conventional Turning |

|

i. Can achieve as tight tolerance as 0.0001" |

i. Suitable for medium to large components |

|

ii. Superior surface finish |

ii. Post-turning operations are required for a good surface finish |

|

iii. The automation feature reduces supervision and cycles |

iii. Manual tool changing, so more supervision is required |

|

iv. Higher initial costs |

iv. Lower initial costs so easily accessible |

|

v. Reduced material waste |

v. More material waste due to tool clearance |

The Role of the Guide Bushing in Swiss Lathes

It is an important part of the Swiss CNC machine which supports the workpiece close to the cutting tools. This stability of the workpiece reduces workpiece vibration and tool deflection. This tool ensures high precision of smaller components for watches, electronics etc.

How Swiss CNC Machines Work

This section will help you understand how a Swiss CNC machine works:

The Swiss CNC Turning Process

The turning process is very simple. Just load a bar stock into the machine's spindle. As the workpiece moves through the machine, guide bushing supports it closer to the cutting tools. There are multiple tools in a Swiss machine, these tools include milling, drilling tools etc. so it is easy to perform multiple operations simultaneously. This simultaneous machining reduces the number of cycles and material waste.

Key Components of a Swiss CNC Machine

The following table includes the key components of a Swiss CNC machine:

|

Components |

Functionality |

|

Guide Bushing |

Supports the workpiece closer to the cutting tools |

|

Spindle |

Rotates the bar stock |

|

Cutting Tools |

Used to remove excessive material |

|

Automatic Bar Feeder |

Used for continuous operations |

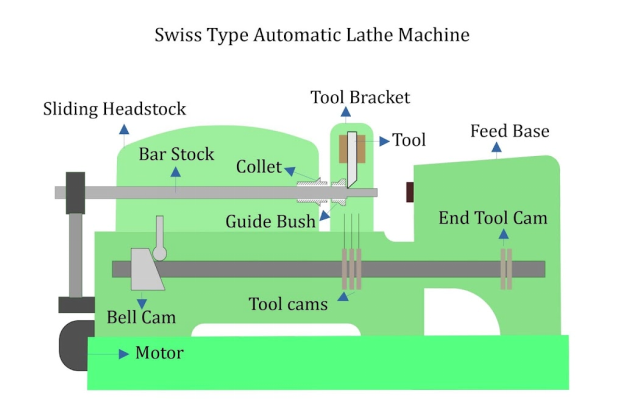

Swiss Lathe Diagram and Key Components

In the above diagram, there are many parts in the machine which make sure the smooth machining of the Swiss CNC machine for precision and tight tolerances of the parts. In all parts, guide bushing, feed base, bar stock and spindle are most important.

Swiss CNC Machine Capabilities

A Swiss CNC machine is capable of many good applications such as it can machine small parts with the highest precision of 0.0001". It can perform multiple operations simultaneously, reducing the number of cycles and maintaining good quality control as well. Due to its capabilities, it is used in critical industries such as aerospace, medical and electronics.

Applications of Swiss Precision Turning Parts

This section presents a detailed information chapter related to the applications of the Swiss CNC machine.

Swiss CNC Machining for Watchmaking: Machining a Swiss Screw

Originally, the Swiss machine, originated from Switzerland, for the watchmaking industry. Since the parts of a watch are very small, that is why it was difficult to machine them with traditional lathe machines.

Aerospace Components and Medical Devices

Aerospace and medical industries are critical industries in which safety standards are very high. To meet those standards, we need very tight tolerance and high precision. Such kind of reliable machining can be done using Swiss-type lathes. The parts from turbine blades to medical devices are machined by Swiss CNC lathes.

Automotive Industry and Small Precision Parts

The components such as fuel injectors and sensors are small, to make sure precision machining Swiss CNC machines are used.

Swiss Machining for Swiss Turned Components

Swiss machines are the best choice for Swiss-turned components. These components are used in various industries from aerospace to medical and electronics to telecommunications.

Swiss Turning for High-Precision Parts

Small and intricate high-precision parts are manufactured using Swiss turning. Higher precision parts include medical implants, fuel injectors, sensors etc.

Advanced Features of Swiss CNC Lathes

In the above section, we have discussed the applications of the Swiss CNC Lathes, the following advanced features are the reason behind their applications.

Multi-Axis Swiss CNC Lathes for Complex Geometry

If a Swiss lathe can produce complex, intricate shapes, it is due to the advanced capabilities of Swiss lathes.

How Swiss Turn Machines Double Productivity

As you know a Swiss machine is equipped with multiple tools and can perform multiple operations including drilling, milling etc. at a time, which is why the production rate is double in this machine.

The Versatility of Swiss Lathes in Producing Small Parts

A Swiss lathe can machine various materials like metals, plastics, composites etc. except ceramic materials with great precision and superior surface finish. That is why it is a versatile tool in producing small parts.

Comparing Swiss CNC Lathes to Other CNC Machines

The initial investment in buying and installing the Swiss lathes is higher but the overall costs are relatively lower than other CNC machines. It excels in greater surface finish and roughness, higher precision and cost-reduction.

Choosing the Right Swiss CNC Machine for Your Application

Let's figure out how to select the right Swiss CNC machine

Best Swiss CNC Machines for Precision Parts

If your parts need higher precision, choose a Swiss CNC machine. You should consider factors such as speed, material or design's versatility, and precision before the selection of a machine.

Swiss Lathe vs. CNC Swiss Turning: Which One Is Best?

It totally depends on the application of the workpiece. If the workpiece is small and requires higher precision, choose a Swiss lathe and if it is large and requires good precision, choose CNC Swiss turning.

Ready to Try Swiss Machining?

We hope this article was interesting for you and it has triggered a thought to try Swiss machining this time. Swiss machining is a reliable tool for your small parts, so you can use it without any doubt for your critical parts.

Working with Tuofa Swiss Machining Service

Toufa is a China-based company which stands with the best machining service. Our company uses fully advanced CNC machines, so the parts match the safety standards. We will deliver our services in the shortest cycles and at the lowest prices.

FAQs

Common Misconceptions About Swiss Machines

Most people think that the Swiss machines are only applicable to smaller components. But it is not like that because it is used to machine various sizes and geometries of the components.

Swiss Turning vs. Screw Machines

For simple geometries, you can use screw machines and for high-precision and complex geometries, you should prefer Swiss turning.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

CNC Machining Cost for Small Batch Aluminum Parts

CNC Machining Cost for Small Batch Aluminum Parts