9 Steps of CNC Turning Machining Parts

Apr 19,2022

Apr 19,2022

The Basic Process of Machining Parts on CNC Lathes

CNC machine tools can better solve complex, precise, small-batch, and changeable part processing problems. It is a flexible and high-efficiency automatic machine tool. Shenzhen Tuofa Metal Fabrication Inc. has 17 years of CNC machining experience and has undertaken various precision CNC parts machining around the world. The following is a brief introduction to the basic process of CNC lathe parts processing:

1. Reasonable selection of machine tools

The main factors considered when machining parts on CNC machine tools are the material and class of the work blank, the complexity of the contour shape of the part, the size, the machining accuracy, the number of parts, and the heat treatment requirements. When choosing a machine tool, it is necessary to ensure the technical requirements of the machined parts and improve the efficiency at the same time.

2.Technological analysis of CNC machining parts

The technical analysis of CNC machining involves a wide range of areas and usually requires that the dimensional data on the part drawings conform to the principle of programming convenience. The dimensioning method on the part drawing should be adapted to the characteristics of CNC machining.

In the drawing of CNC machining parts, the dimensions should be quoted on the same data, or the coordinate dimensions should be given directly, and the conditions of the geometric elements constituting the part outline should be sufficient. The structural manufacturability of the processing part should conform to the characteristics of CNC machining. This labeling method is not only convenient for programming but also facilitates the coordination between dimensions, which improves efficiency.

3.Selection of processing methods

The selection principle of the machining method is to ensure the machining accuracy and surface roughness of the machined surface. Since there are generally many processing methods to obtain the same level of precision and surface roughness, it is necessary to comprehensively consider the shape, size, and heat treatment requirements of the parts in the actual selection. In addition, productivity, economic requirements, as well as actual conditions such as production equipment, should also be considered.

4.The principle of determining the processing plan

The machining of relatively precise surfaces on parts is often achieved gradually through roughing, semi-finishing, and finishing. For these surfaces, it is not enough to select the corresponding final processing method only according to the quality requirements, but also to correctly determine the processing plan from the blank to the final shape.

When determining the processing plan, the processing method required to meet these requirements should be preliminarily determined according to the requirements for the accuracy and surface roughness of the main surface.

5.The division of process steps

The process of machining parts on CNC machine tools can be relatively concentrated, and most or all of the processes can be completed in one clamping as much as possible. First of all, according to the part drawing, consider whether the processed part can be processed on a CNC machine tool. If not, it should be decided which part is processed on the CNC machine tool and which part is processed on other machine tools. That is, dividing the processing procedures of the parts.

6.Parts installation and fixture selection

The installation of parts strives to unify the benchmarks of design, process, and programming calculation, and avoids the use of manual adjustment processing schemes. As efficient as possible, all surfaces to be machined are machined after one positioning and clamping.

Ensure that the coordinate direction of the fixture is relatively fixed with the coordinate direction of the machine tool, and that the components on the fixture should not hinder the machining of the surfaces of the parts by the machine tool. That is, the fixture should be opened for its positioning, and the clamping mechanism components should not affect the cutting tool during processing (such as collision, etc.).

7.Selection of tools and determination of the cutting amount

The choice of tool is one of the important factors in the CNC machining process. It not only affects the machining efficiency of the machine tool but also directly affects the machining quality. When programming, the selection of tools usually considers factors such as the processing capacity of the machine tool, the content of the process, and the material of the workpiece. The cutting amount includes the spindle speed (cutting speed), the amount of back cutting, and the amount of feed.

8.The choice of cutting oil

Cutting oil plays a role in protecting the tool and improving the machining efficiency throughout the machining process. When selecting cutting oil, it is usually necessary to decide which cutting oil to use according to the material of the workpiece, the type of equipment, the process method, the performance of the tool, and other factors. In addition to the above direct factors, other properties of the cutting oil are also required to meet the requirements, such as anti-oxidation properties, anti-rust properties, cooling properties, etc.

9.The determination of the processing route

In CNC machining, the trajectory of the tool position relative to the workpiece movement is called the machining route, which requires high positioning accuracy and the positioning process to be as fast as possible. In addition, the axial movement size of the tool should be determined, which is mainly determined by the hole depth of the machined part, but some auxiliary dimensions, such as the introduction distance and overrun of the tool, should also be considered.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

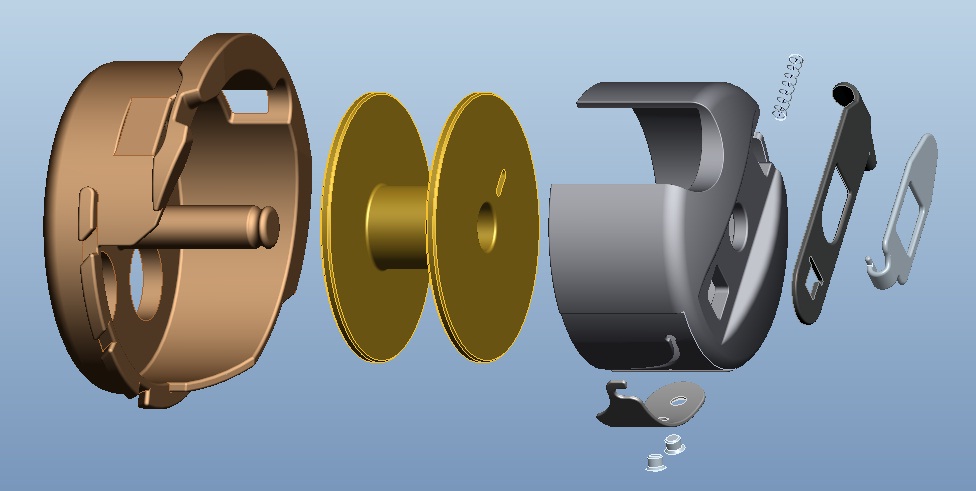

5 Key Points of Custom Mechanical Keyboard

5 Key Points of Custom Mechanical Keyboard