Authoritative Design Process of Plastic Parts - Worth Collecting!

Dec 01,2022

Dec 01,2022

The structural design principles of China Shenzhen Tuofa CNC Machining for product development:

a. The structural design should be reasonable: the assembly clearance is reasonable, and all plug-in structures should reserve clearance; ensure sufficient strength and rigidity (safety test), and properly design a reasonable safety factor.

b. The structural design of plastic parts should comprehensively consider the manufacture ability of the mold, and simplify the manufacture of the mold as much as possible.

c. The structure of plastic parts should consider its plasticity, that is, the production efficiency of parts injection molding should be high, and the scrap rate of injection molding should be reduced as much as possible.

d. Consider the convenience of assembly production (especially not to conflict with assembly).

e. The structure of plastic parts adopts standard and mature structure as far as possible, so-called modular design.

f. For those that can be used in general/common use, use existing parts as much as possible, and do not open new molds.

g. Taking into account the cost

Plastic Parts Design Steps

Plastic parts are structural designs based on industrial modeling. First, check whether there are similar products for reference, and then perform a detailed functional decomposition of the products and parts to determine the splitting, wall thickness, demoulding slope, and gap between parts. The main process issues such as transition treatment, connection treatment, and strength treatment of parts.

1. Similar reference

Before designing, you should first search for your company's excellent products, find out what problems and shortcomings have occurred in the original products, and refer to the existing mature structure to avoid problematic structural forms.

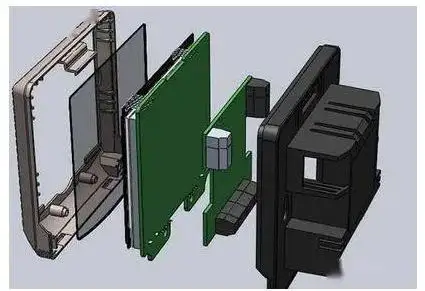

2. Determine the splitting of parts, the transition between parts, connection and gap treatment

Understand the modeling style from the modeling drawing and effect drawing, cooperate with the functional decomposition of the product, determine the number of parts to be divided (different surface states are either divided into different parts, or there must be over-processing between different surfaces), and determine the surface of the part The excessive processing between the parts determines the connection mode between the parts and the fit gap between the parts.

3. Determination of part strength and connection strength

According to the size of the product, determine the wall thickness of the main body of the part. The strength of the part itself is determined by the wall thickness of the plastic part, the structural form (the strength of the plastic part in the shape of a flat plate is the worst), the reinforcing rib and the reinforcing bone. While determining the individual strength of the parts, the connection strength between the parts must be determined. The methods of changing the connection strength include adding screw columns, adding stoppers, adding buckles, and adding reinforcement bones for lower support.

4. Determination of demoulding slope

The demoulding slope should be based on the material (PP, PE silica gel, rubber can be forcibly demolded), the surface state (the slope of the embossed surface should be larger than that of the smooth surface, and the slope of the etched surface should be 0.5 degrees larger than the model requirements as much as possible. , to ensure that the etched surface is not damaged, and to improve the yield of the product), whether it is transparent or not determines the demoulding slope that the part should have (the transparent slope should be large) and other factors are determined comprehensively.

The types of materials recommended by the company's different product lines

| Type | Part Classification | Recommended materials | Mark column | Attention |

| 1 | Wrench | Flame retardant ABS | Flame retardant ABS | Grains must be taken when adding color; Vacuum plating, poor electroplating performance. |

| 2 | Small panel class | Flame retardant ABS | HF-606 | Grains must be taken when adding color; Vacuum plating, poor electroplating performance. |

| 3 | Guide rail | PA66,glass fiber | PA66-RG25 | The surface of the parts looks rough, and the color is difficult to mix. This material is brittle and has poor toughness. Small structures such as the buckle on the structural parts are easy to break. Fillets should be added in the structural design to enhance the strength. |

| 4 | Lamp mirror and light guide column | PMMA, PA | PMMA560F | Transparent PC has good toughness, is not easy to crack, is expensive, and has poor light transmittance. PMMA is brittle, with good light transmittance and lower price. The liquidity of PC and PMMA is not good, so the design should take full account. |

| 5 | Lens,transparent window | Transparent PC | Dow 302-05 | |

| 6 | Dust screen | Flame retardant ABS | PPK15X13H/B |

The ambient temperature is too high: consider changing the material. |

| 7 | Signage | Electroplating materials | ABSPA-757 | Double material injection molding process is complex |

Surface treatment of plastic parts

| Type | name | Process | Effect | matter |

| 1 | Plastic original smooth surface | Mold cavity surface polishing | The plastic surface is smooth and bright | The higher the dimensional accuracy of the die surface, the higher the surface finish, and the more uniform the luster of the part |

| 2 | Plastic primary texture | On the basis of polishing the mold surface, paint the plastic surface with decorative lines | The plastic surface presents tiny texture, and the surface has different luster states |

The etched plate is divided into light grain, semi light grain and sub light grain; Generally, the coarse grain is not used in conjunction with fuel injection. The thinner the etched plate, the less resistant to scratching. The matt grain is easy to scratch. |

| 3 | Plastic surface oil spraying | Spray the plastic surface | It can obtain surfaces with different colors, different luster states and different wear resistance | The painting has bright and matt effects. The painting can obviously improve the appearance grade of the plastic part surface, but the cost also increases a lot |

| 4 | Plastic surface silk screen | Local printing on the surface of plastic parts | It can print words and patterns, and has different color states | Its effect mainly depends on the ink and color |

| 5 | Vacuum plating on plastic surface | Vacuum plating | It can have different colors, different gloss states, and can be made into semi transparent lamp mirrors or lamp plates | The luster depends on the original state of the plastic color depends on the vacuum plating itself; Vacuum plated products are not wear-resistant. Generally, UV spraying is required after vacuum plating to improve the wear-resistance. |

| 6 | Plastic surface electroplating | Plastic electroplating | It can have different colors and different luster, but it can not make translucent products | Glossiness depends on the original state of plastic; The color depends on the plating itself; Electroplated products have good wear resistance; Some plastic materials cannot be electroplated |

| 7 | Plastic surface IMD | The process can be understood as covering a printable film on the surface of the plastic | The abrasion resistance of the film itself can basically be achieved by printing, which can be achieved on the plastic surface | The film is generally covered on the surface, which can be covered with white film. Silk screen is printed on the film or behind the workpiece, and UV paint is sprayed for pad printing. This method has process design requirements for acute angle and convex concave. |

| 8 | Plastic surface IML | The film layer is relatively thick, which can be understood as a separate part and can be superimposed on the surface or inside of the plastic | The film itself is wear-resistant and can achieve three-dimensional effect by using the thickness of the film | The film is generally covered on the surface. This method has process design requirements for acute angles and convex concave. |

Technical Requirements for Plastic Parts

Wall thickness selection of plastic parts(mm)

| Plastic type | Minimum wall thickness | Wall thickness of small parts | Wall thickness of medium parts | Wall thickness of large parts |

| ABS | 0.75 | 1.25 | 1.6 | 3.2-5.4 |

| Fireproof ABS | 0.75 | 1.25 | 1.6 | 3.2-5.4 |

| PA66+glass fiber | 0.45 | 0.75 | 1.6 | 2.4-3.2 |

| PMMA | 0.8 | 1.5 | 2.2 | 4-6.5 |

| Transparent PC | 0.95 | 1.8 | 2.3 | 3-4.5 |

Plastic parts have requirements on the uniformity of wall thickness, and workpieces with uneven wall thickness will have shrinkage marks. It is required that the ratio of the reinforcement rib to the wall thickness of the main body should be less than 0.4, and the maximum ratio should not exceed 0.6.

Draft angle of plastic parts

In the construction of the three-dimensional drawing, it is necessary to draw the slope where it affects the appearance and assembly, and the reinforcement generally does not draw the slope.

The draft angle of a plastic part is determined by the material, the state of the surface decoration, and whether the part is transparent or not. Rigid plastics have a larger demoulding slope than soft plastics, and the higher the part, the deeper the hole and the smaller the slope. The public account "Mechanical Engineering Literature", a gas station for engineers!

| Serial No | Main aspects affecting demoulding angle | |

| 1 | Impact of plastic materials | PE and PP can be forced to demould, and the forced demoulding modulus generally does not exceed 5% of the maximum sectional area of the core. |

| 2 | Influence of decorative pattern | In general, the demoulding angle is 0.5 degree greater than that allowed by the etched plate |

| 3 | Effect of transparency prevention of workpieces | Transparent workpieces are generally 3 degrees |

| 4 | General value | 0.5~1.5 degrees under normal conditions |

Recommended draft angles for different materials

| Plastic type | Cavity inclination | Core inclination |

| ABS | 40 "~1.2 degrees | 35 '~1 degree |

| Fireproof ABS | 40 "~1.2 degrees | 35 '~1 degree |

| PA66+glass fiber | 25’~45” | 20”~40% |

| PMMA | 35 "~1 degree 30" | 30 "~1 degree |

| Transparent PC | 35 "~1 degree | 30”~50” |

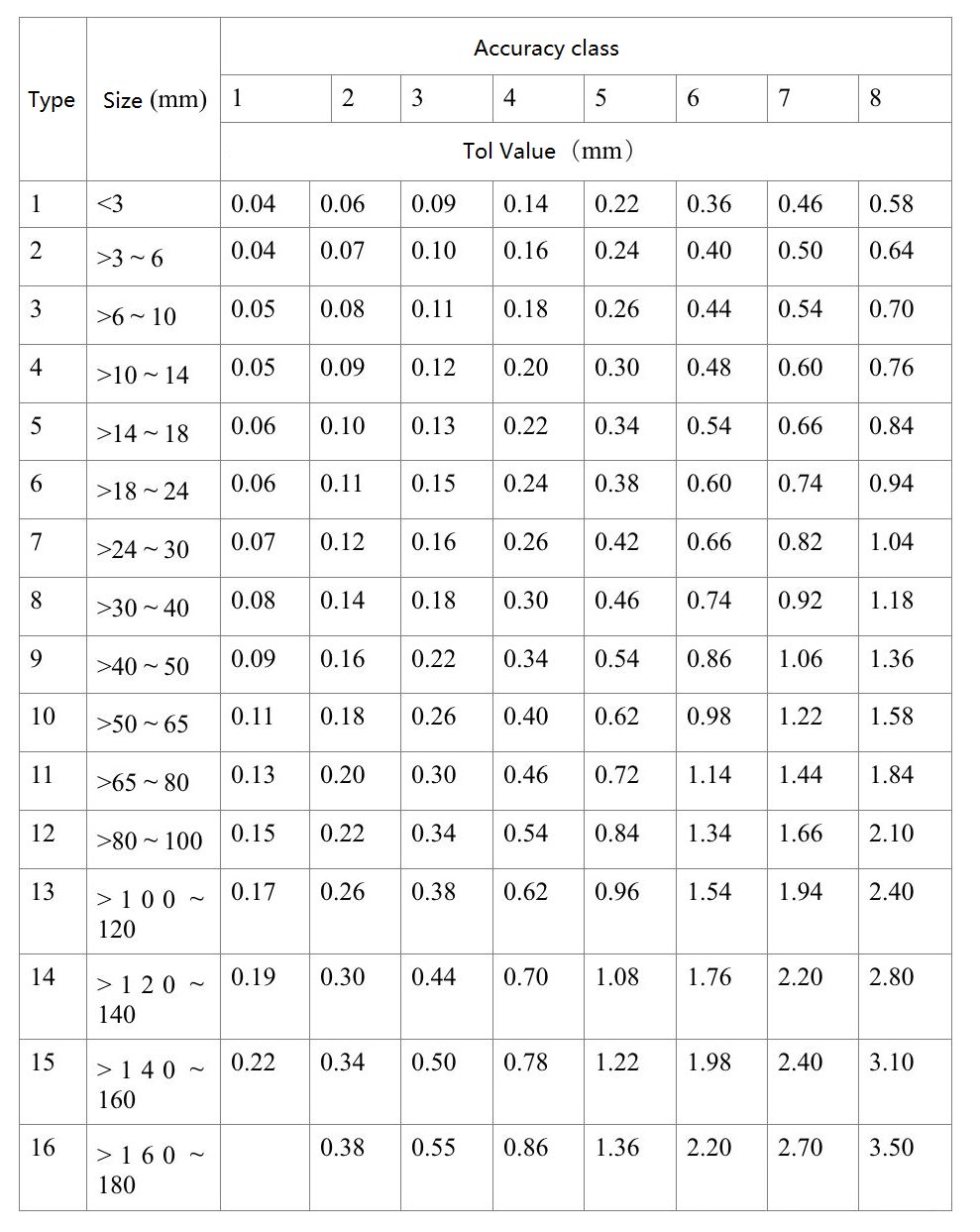

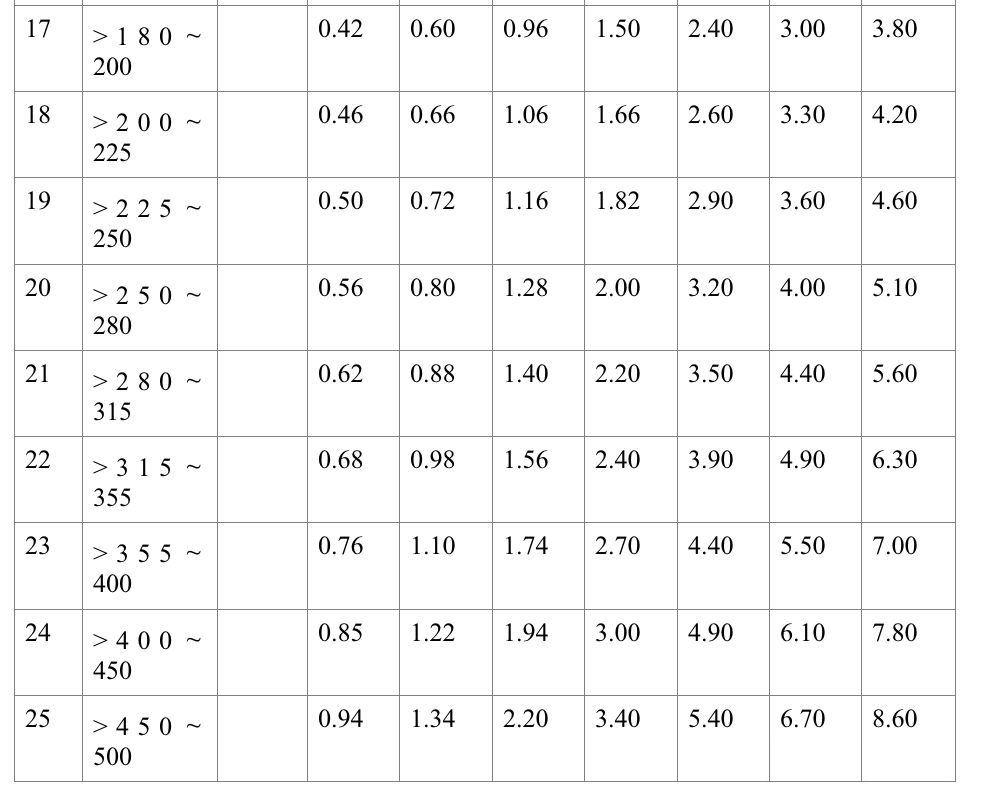

Values with Different Precision in Different Size Ranges

Dimensional accuracy of plastic parts

Generally, the precision of plastic parts is not high. In actual use, we mainly check the assembly size, and mark the overall size, assembly size, and other dimensions that need to be controlled on the plan.

In practice, we mainly consider the consistency of dimensions, for example, the sides of the upper and lower covers need to be aligned,

Economical precision for different materials used

| Plastic type | Recommended accuracy class | |||

| High-precision | General accuracy | Low precision | Undeclared tolerance | |

| ABS | 2 | 3 | 4 | 5 |

| Fireproof ABS | 2 | 3 | 4 | 5 |

| PA66+glass fiber | 3 | 4 | 5 | 6 |

| PMMA | 2 | 3 | 4 | 5 |

| Transparent PC | 2 | 3 | 4 | 5 |

| PC+ABS | 2 | 3 | 4 | 5 |

| Let's Start A New Project Today |

| Get a Free Quote |

Determinants of Surface Roughness

Surface roughness of plastic

1) The roughness of the etched surface cannot be marked. In places where the plastic surface finish is particularly high, circle this range and mark the surface state as a mirror surface.

2) The surface of plastic parts is generally smooth and bright, and the surface roughness is generally Ra2.5~0.2um..

3) The surface roughness of the plastic mainly depends on the surface roughness of the mold cavity, and the surface roughness of the mold is required to be one to two levels higher than the surface roughness of the plastic parts. The surface of the mold can reach Ra0.05 by ultrasonic and electrolytic polishing.

Fillet

The fillet value of injection molding is determined by the adjacent wall thickness, generally 0.5 to 1.5 times the wall thickness, but not less than 0.5mm.

The position of the parting surface should be carefully selected with rounded corners. There are rounded corners on the parting surface, and the rounded part needs to be on the other side of the mold. It is difficult to make, and there are subtle traces at the rounded corners. But rounded corners are required when cut-resistant hands are required.

Rib problem

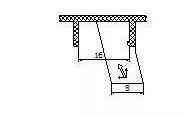

The injection molding process is similar to the casting process, and the unevenness of the wall thickness will cause shrinkage defects. Generally, the wall thickness of the rib is 0.4 times the thickness of the main body, and the maximum is not more than 0.6 times. The spacing between the ribs is greater than 4t, and the height of the ribs is lower than 3t, as shown in Figure 6-1. In the method of improving the strength of the part, the reinforcement is generally added without increasing the wall thickness, as shown in Figure.

The rib of the screw column should be at least 1.0mm lower than the end surface of the column, and the rib should be at least 1.0mm lower than the surface of the part, or the parting surface.

When multiple ribs intersect, attention should be paid to the uneven wall thickness caused by the intersection.

Rib Design for Plastic Parts

Bearing surface

Plastic is easy to deform, and should be classified as the positioning of blanks in terms of positioning. The positioning area should be small, such as plane supports, which should be changed to small bumps and convex rings.

Sloping roof and row position problem

The inclined top and the row position both move in the parting direction and perpendicular to the parting direction. There should be no rubber position to block the movement of the inclined roof and the row position in the direction perpendicular to the parting mold, and there must be enough space for movement, as shown in the figure below

The Processing Method of the Limit Process Problem of Plastic

1) Special treatment method for wall thickness

For particularly large workpieces, such as toy car shells, the method of multi-point glue injection can make the wall thickness relatively thinner. The local glue position of the column is thick, and the method as shown in the figure below is used to deal with it.

2) Treatment of small slope and vertical surface

The mold surface has high dimensional accuracy, high surface finish, low demoulding resistance and small demoulding slope. In order to achieve this purpose, the small slope of the workpiece is individually inlaid, and the insert is cut by wire and processed by grinding, as shown in the figure

To ensure that the side wall is vertical, a running position or a slanted roof is required. There are interface lines in the running position. In order to avoid obvious interfaces, the wiring is generally placed at the junction of the rounded corner and the large surface.

To ensure that the side wall is vertical, a running position or a slanted roof is required. There are interface lines in the running position. In order to avoid obvious interfaces, the wiring is generally placed at the junction of the rounded corner and the large surface, as shown in the figure

Problems That Often Need to be Solved in Plastic Parts

1) Transition processing issues:

The precision of plastic parts is generally not high, and there must be transitional treatment between adjacent parts and between different surfaces of the same part.

Small grooves are generally used to transition between different surfaces of the same part, and small grooves can be used between different parts to deal with high and low staggered surfaces, as shown in the figure

Surface over treatment

2) The clearance value of plastic parts:

Direct assembly between parts, generally 0.1mm if there is no movement between them;

The seam is generally 0.15mm;

The minimum gap between parts without contact is 0.3mm, generally 0.5mm.

3) The common forms and gaps of plastic parts are as shown in the figure

Common Forms and Clearance Methods of Seats of Plastic Parts

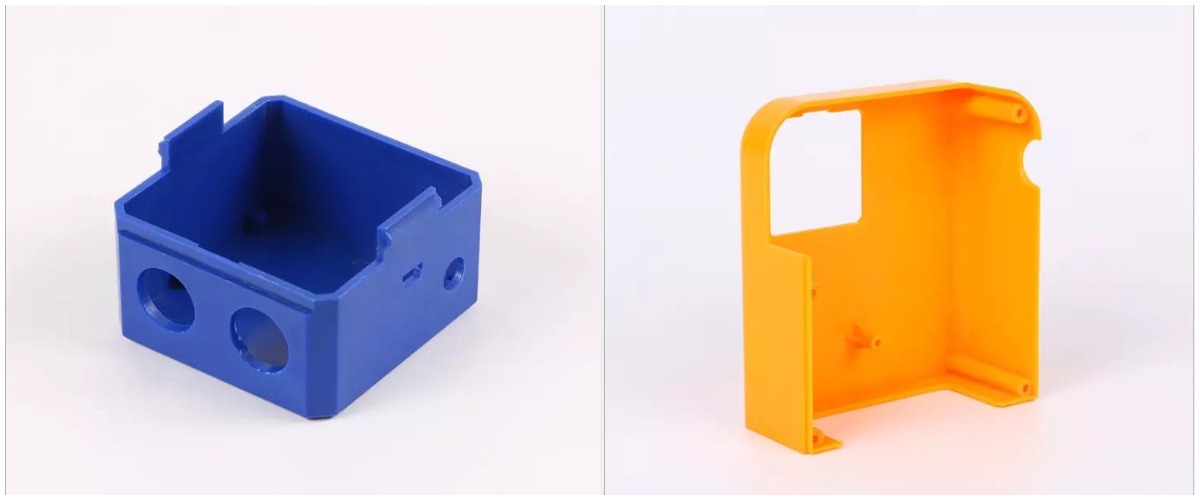

Plastic Parts are Entering the Field

1. Replace the sheet metal case cover with a plastic case cover;

2. Replace the electroformed sign with a double-color injection sign;

3. Tuofa is replacing the metal anti-static small panel with an anti-static plastic small panel;

4. Tuofa is replacing small metal shielding panels with plastic shielding panels;

|

Try Tuofa Now! Tuofa Engineer Support Team - Real human quotes are more accurate than software quotes |

Get a free quote |

Tuofa CNC Machining starts from the quality of plastic products. Plastic products are not only closely related to plastic product performance, molding process and mold design, but also depend on whether the structural design of injection products conforms to molding and mold manufacturing processes.

Only when the structural design of plastic products meets the process requirements can a reasonable mold structure be designed and the products can be molded smoothly, so as to achieve the purpose of improving labor productivity, ensuring product quality and reducing production costs.

Tuofa CNC Machining not only has first-class technology in the design of plastic parts, but also has outstanding performance in the design and manufacture of metal parts. If you want to know more, contact us and give you a surprise.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

How to Lock The Bolts From Loosening?

How to Lock The Bolts From Loosening?