Drilling vs Boring vs Reaming: What's the Difference?

Feb 20,2025

Feb 20,2025

Holes in a workpiece serve as a channel for wires, bolts or liquid to enhance functionality. It is an important part in production process and can be formed by various techniques. Commonly used methods are drilling, boring and reaming. These methods fundamentally have same purpose, but these are different in terms of working, advantages and applications. It is important to understand the basics of all these operations to choose ideal method for required applications. So, lets find that out in this article in detail.

What Is Drilling?

It is one of the common methods of hole-making in a workpiece. The cutting tool drill bit rotates at higher speed. This makes a hole inside the workpiece. It can be applied on metals, alloys, plastic, composites and wood.

Overview of Drilling

To drill a hole, the drill bit is pressed against the material's surface which starts rotating at higher speed. This rotation cuts the edges and grooves created in the workpiece. These groves generate holes along with releasing chips. It can be carried out manually, power drill or automated. Automated CNC drilling is used for precision and accuracy.

Types of Drilling

Drilling method has different types.

Twist Drilling

It is a very common technique in drilling. A twist drill bit is used with having rod-shaped shaft and spiral grooves along the length. It is a general-purpose drill. This method can be used in non-specialist projects.

Gun Drilling

This is used to form deep holes. A higher depth-to-diameter ratio is created which ranges from 1-40mm. The hole depth is beyond that can be made from conventional methods

Micro-Drilling

Micro-drilling creates very small holes. It is a precision technique done with very small drill bits. This method is mostly used to make medical devices. it is also suitable for aircrafts and electronic parts and for watches by CNC drilling

Advantages and Disadvantages of Drilling

Drilling has many advantages.

- It serves as primary procedure of hole-making unlike boring or reaming with a fast production rate

- It is an easy machining method and suitable for mass production.

- It is famous in almost all industries because of a cost-effective technique

However, drilling has some limitations:

- It creates surface quality issues in workpiece like cutting lines or scale and require an additional process for finishing.

- Tool life can be affected if continuously used for a longer time or wrong drill bit is selected.

What Is Boring?

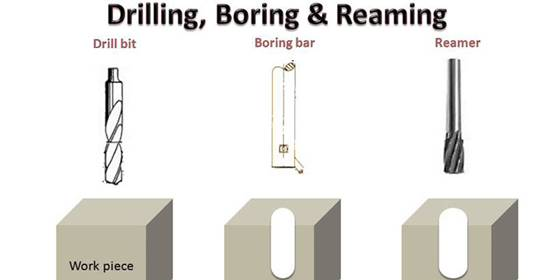

This is a hole enlargement process for pre-drilled holes. Boring bar is used as cutting tool which has a single point. Boring enhances the accuracy and surface finish and improves the defects in hole.

Boring Definition in Machining

In machining, boring process the existing holes. It is used to enhance the surface quality and accuracy of holes.

Boring vs Drilling

The key difference between boring and drilling is drilling is a hole-making process while boring is hole enlargement process. If hole needs a quality finish, refining and precision, boring is used

Boring Process

A boring bar removes the material from the inner surface of a hole and increases its diameter. It is normally carried out after drilling and is a slower process for providing accuracy. It is used where high tolerance is needed. Boring mills or lathe are used for the bore hole.

What Is Reaming?

It is a hole finishing process and utilized to enhance smoothness, precision and roundness of holes. It is a final process done by the reamer. A small amount of material is removed and refine the walls of holes. Reamming is specially utilized where high tight tolerance and dimensional accuracy is required.

Reaming Process Overview

Cutting tool is moved along the hole axis. To get accuracy, correct alignment with the axis is essential. Reamer starts rotating and removes thin layers of material from the wall. It increases the surface finish of inner walls. It can be carried out manually or by powered machines. Machnies are normally lathes, drilling or milling machine.

Boring vs Reaming

Both are cutting processes. But boring used single point cutting tool. And it basically enlarges existing holes. Reamer has a multi-pointed cutting tool. And it is used to improve surface finish and dimensional accuracy of holes.

What is the Difference Between Boring and Drilling, Reaming?

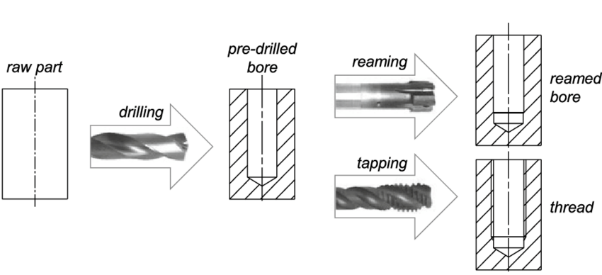

Drilling is the first step and used for hole-making. Boring is a hole enlargement process and used to sizing the pre-drilled holes. Reaming is a hole finishing process and improves accuracy of holes.

What is the main purpose of a boring operation as compared to drilling?

The primary purpose of boring is to sizing the pre-drilled holes. Drill is the first step of machining. Without drilling boring cannot be carried out. Boring is essential to get precision and to achieve dimensional accuracy of holes.

Machining Method Comparison

- Drilling: it is the fastest process among all. Therefore, the dimensional accuracy of hole is the poorest in drilling

- Boring: bore holes are slower than drilling and has better hole precision.

- Reaming: it is the slowest process and has a small blade cutting tool. It finely tuned the hole size and surface finish

Differences in Tools

- Drilling used drill bit as a cutting tool. It creates new holes.

- Boring uses boring bar which is single pointed cutting tool and resizes the existing holes

- Reaming uses reamer that is a multi-pointed tool and finely smoothens the surface of holes.

Speed and Precision

- Drilling has the fastest machining speed among all but gives the least precise results.

- Boring is slower than drilling but gives high precision and to refine the hole alignment

- Reaming is a hole finishing process and normally performed at the slowest speed and has the highest precise results.

Machining Material Type

- Drilling uses high speed steel to create holes. But if high wear resistance is needed. Carbide tools are used

- Boring used carbide-tipped holes to refine the hole size

- Reaming uses high-quality carbide tools to get higher accuracy.

Hole Size

- Drilling is the initial step. A large amount of material is removed as chips to create a big enough hole size

- Boring is for resizing the hole. A less material is removed to enlarge the hole size

- Reaming has the least material removal to finish the hole size.

Tables of Boring vs Drilling vs Reaming

|

Features |

Drilling |

Boring |

Reaming |

|

Purpose |

Create new holes |

Enlarge existing holes |

To surface finishes the hole |

|

Cutting tool |

Drill bit |

Boring bar |

Reamer |

|

Precision |

Less |

More |

Highest |

|

Machining speed |

Faster |

Slow |

Slower |

What Are the Similarities Between Drilling and Boring?

The similarities among all these machining processes are:

- All are hole precision machining techniques

- All are used for material removal process

- All can be done manually, or by CNC drilling or others

- All can work with almost every type of material like metal, alloy, plastic, wood, composite.

- They all require coolants and lubricant to avoid tool wear and to get optimum results.

Drilling and Boring Machine Capabilities

Versatility of Machines

Boring machines are more versatile than drilling. They can do hole refining with higher accuracy. Drilling has the key role of creating new holes.

Applications

Both are used in construction and manufacturing. The common uses are for engine blocks, pumps and gear components. Additionally, for drill holes in building materials, and making parts for aerospace, marine, and tooling.

What are the Advantages of Boring over Drilling?

- The primary benefit is the higher accuracy of holes

- It offers higher surface finishes

- It is best for applications where high dimensional tolerance and quality is needed

When to Use Drilling, Boring, or Reaming?

Drilling

It creates holes and has faster production time. It offers moderate tolerance

Boring

It is used to enlarge existing bore holes. It also smoothens and refines the hole alignment

Reaming

It refines the size and surface quality. It gives precise hole dimensions with smooth walls.

Drilling vs Boring vs Reaming: Summary

In the manufacturing industry, drilling is used to process new holes. A drill bit rotates on a stationary workpiece to create holes. Boring is utilized to enlarge that hole and for hole alignment. Boring bar is used in bore holes which have multiple edges. It removes small amounts of material than drilling. Reaming is a hole finishing process which finely smooths the hole to precise diameter and quality. All have many uses in manufacturing and construction industries.

FAQs

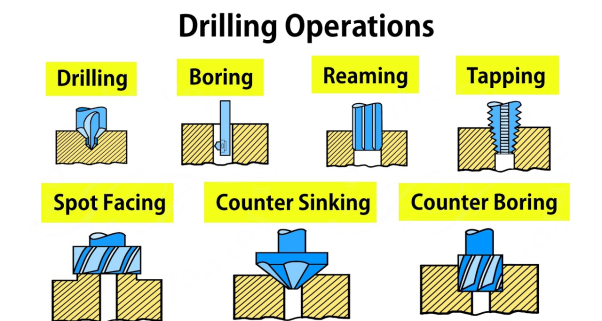

What is Counter Boring in Drilling?

It refers to enlarging the existing hole to a specified depth. It creates a round cavity with larger diameter at the top to place the head of screw of bolts. It essentially has flat bottom with wider top section of hole

Difference Between Drilling and Tapping

Drilling is a new hole making process by using drill bit. Tapping is a process of creating cutting thread inside an existing hole to fit a screw or bolt. Drilling is done first which is followed by tapping to create threads for fastener in holes

Boring vs Trenching

Boring is a hole enlargement process in a less disruptive way. While trenching is a traditional method to dig underground.

Boring vs Drilling Cost

Boring is costly than drilling because it is a precision machining process and requires specialized tools and skilled labor

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Tool Wear Patterns: Types and Solutions

Tool Wear Patterns: Types and Solutions