Understanding Copper And Why Dosen't Copper Rust

Jul 10,2024

Jul 10,2024

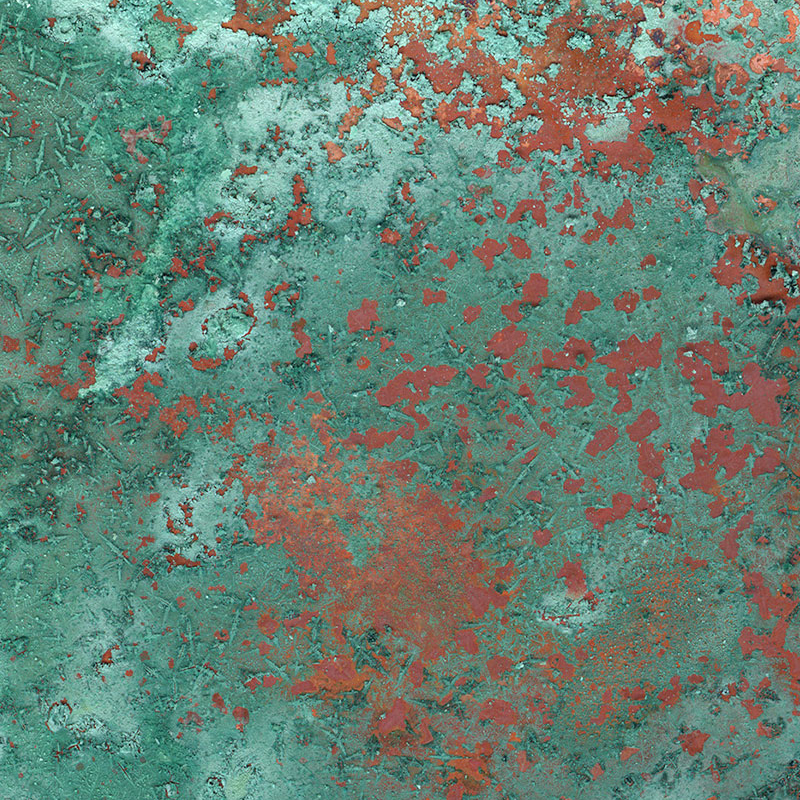

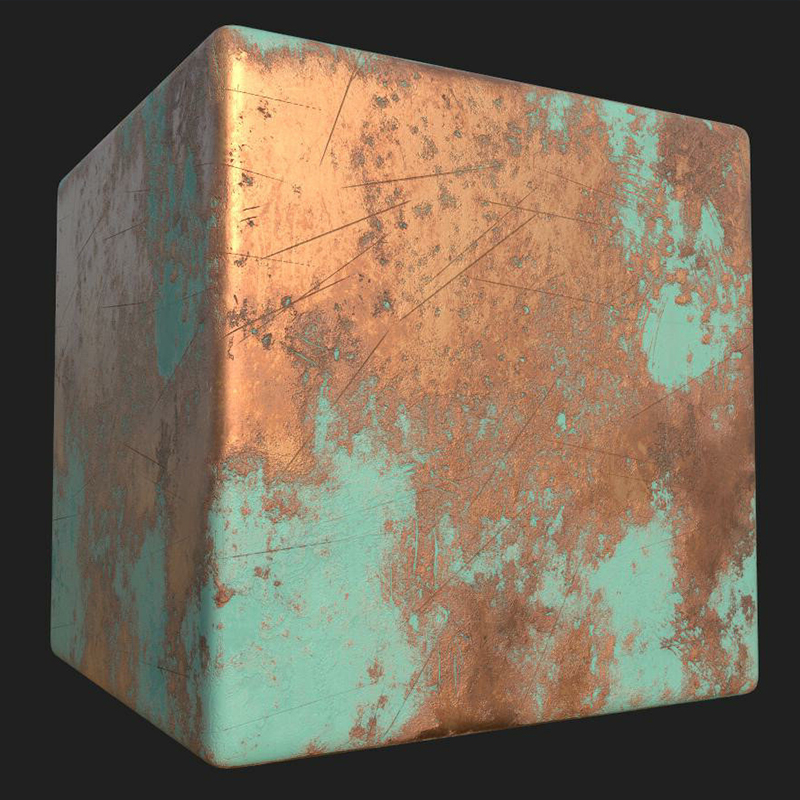

Copper is a useful metal that humans have used for thousands of years. It oxidizes but doesn’t rust. Instead, it forms a green layer called patina, which protects it from further damage. This oxidation process makes copper highly durable, allowing it to resist damage from the elements and maintain its strength over time.

The Chemical Nature of Copper

Copper, atomic number 29, is reddish-brown, highly conductive, malleable, and forms a protective patina when oxidized, preventing further corrosion. Copper CNC Machining.

Basic Chemical Structure of Copper

Copper is an element with an atomic number of 29. It has a distinctive reddish-brown color and is known for its excellent conductivity of electricity and heat. Copper's atomic structure consists of a single electron in its outermost shell, which allows it to easily participate in chemical reactions and form compounds.

|

Property |

Value |

|

Atomic Number |

29 |

|

Atomic Mass |

63.546 |

Conductivity and Malleability

Copper's high conductivity is due to the free movement of its outer electron, making it an ideal material for electrical wiring. Additionally, copper is highly malleable and ductile, allowing it to be drawn into thin wires or hammered into sheets without breaking.

Copper's Reaction with Oxygen

When exposed to air, copper undergoes a slow oxidation process. However, unlike iron, which forms rust, copper forms a protective layer on its surface known as patina. This patina is primarily composed of copper oxide, which acts as a barrier against further oxidation.

Rusting vs. Tarnishing

Rust is iron oxide that weakens iron and steel, while tarnish is copper sulfide or oxide forming a protective layer on copper, preventing further corrosion. https://www.tuofa-cncmachining.com/

What is Rust?

Rust is a form of iron oxide that occurs when iron reacts with oxygen and moisture. The chemical composition of rust includes hydrated iron oxide. Rust weakens the structural integrity of iron and steel, causing significant damage over time. Is Rust Magnetic?

Copper Tarnish Explained

Copper tarnish is a result of copper reacting with sulfur or oxygen over time, forming copper sulfide or copper oxide. This reaction leads to a darkening of the copper surface, which is often seen as a greenish or bluish patina in outdoor environments.

Chemical Reaction Leading to Tarnish

Copper reacts with sulfur compounds in the air to form copper sulfide.

Difference Between Rust and Tarnish

While rust weakens metals like iron by causing flaky, brittle structures, tarnish forms a protective layer on copper. This tarnish prevents further corrosion, making copper more durable compared to metals that rust.

Protective Layer of Copper

Patina on copper forms a protective layer of copper carbonate or sulfate, preventing further oxidation. It gives a greenish hue, influenced by air, moisture, and pollutants.

Patina Formation

The patina is a layer of copper carbonate or copper sulfate that forms on copper surfaces exposed to the elements. This layer not only gives copper its characteristic green color but also protects the underlying metal from further oxidation.

|

Patina |

Characteristics |

|

Copper Carbonate |

Green color, protective layer |

|

Copper Sulfate |

Blue-green color, protective layer |

How Patina Protects Copper

The patina acts as a barrier, preventing oxygen and moisture from reaching the copper underneath. This stops the oxidation process and preserves the metal's integrity.

Visual Characteristics of Patina

Patina is often seen as a desirable aesthetic feature, especially in architectural elements. Its greenish hue adds a vintage or rustic appearance to buildings and statues.

Influence of Air and Moisture

Air and moisture significantly affect the formation of patina on copper. In humid environments, patina forms more rapidly due to increased moisture levels. Pollutants such as sulfur dioxide (SO2) in the air can also accelerate tarnishing.

How Different Environments Affect Copper

In coastal areas, the presence of salt in the air can lead to the formation of copper chloride (CuCl2), which has a blue-green color. Industrial areas with high sulfur content in the air can cause rapid tarnishing due to the formation of copper sulfide.

Applications and Benefits of Copper

Copper is used in electrical wiring, plumbing, and electronics due to its high conductivity, corrosion resistance, and antimicrobial properties, offering durability and reliability.

Common Uses in Industry

Copper is widely used in various industries due to its excellent properties.

Electrical Wiring

Copper's superior conductivity makes it the preferred material for electrical wiring. It ensures efficient transmission of electricity with minimal energy loss.

Plumbing

Copper pipes are commonly used in plumbing due to their durability and resistance to corrosion. They are safe for drinking water and can withstand high temperatures.

Architectural Elements

Copper is used in roofing, gutters, and downspouts. Its patina provides a natural protective layer that enhances the lifespan of these architectural elements.

Longevity and Durability

Copper has a long lifespan due to its resistance to corrosion and wear. It can last for decades, making it a cost-effective material in the long run.

Resistance to Corrosion

Unlike iron and steel, copper does not rust. Its ability to form a protective patina ensures that it remains intact and functional even in harsh environments.

Maintenance and Care for Copper Items

Maintain copper by regular cleaning with vinegar and salt or lemon and baking soda, apply wax to prevent tarnish, store in dry places, inspect regularly, and avoid harsh chemicals.

Cleaning and Polishing

To maintain copper's appearance and functionality, regular cleaning and polishing are essential.

Methods to Clean Copper

Clean copper using a vinegar and salt solution or lemon juice and baking soda mixture. Both methods effectively remove tarnish, restoring copper’s shine naturally.

Preventing Tarnish

Prevent copper tarnish by applying a thin wax layer, storing items in dry places, using dehumidifiers, and avoiding exposure to moisture and pollutants.

Long-term Preservation

For long-term preservation of copper, inspect regularly, clean gently with soft cloths, avoid harsh chemicals, apply protective wax, and control humidity using dehumidifiers.

Conclusion

Copper is a remarkable metal with unique properties that make it invaluable in various industries. Tuofa CNC machining services in China utilize copper's ability to resist rust and form a protective patina, setting it apart from other metals and ensuring longevity and durability. By understanding the nature of copper and implementing proper maintenance techniques, you can maximize the benefits of this versatile material.Click here to get a free quote.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is Galvanizing: 6 Methods, Uses, Benefits

What is Galvanizing: 6 Methods, Uses, Benefits