What is Mechanical Testing | Material Testing Solutions Introduction

Sep 09,2023

Sep 09,2023

Mechanical Testing plays a crucial role in the field of material science. They help in the selection of appropriate materials, their characterization, and the validation of final products under various conditions. Mechanical testing can be performed by various methods.

This article will provide you with an overlook of the different types of mechanical testing. And also give information about their usage and application in product design and part manufacturing.

What is Mechanical Testing

Mechanical testing finds extensive application in the field of material science and engineering. With the help of mechanical Testing behavior of material under specific loads and conditions can be determined. In this process, materials are subjected to loads in a controlled manner. Then the responses of the material are observed. In these methods materials' ability to withstand loads under certain conditions in which it is finally going to be used are found. It helps scientists, researchers, and engineers make an informed decision while selecting material.

Mechanical Testing Examples

It includes various methods in order to find the reliability and strength of a material at various conditions. In mechanical testing for example; the tensile test is used to find the tensile strength of materials, Charpy test tells about its behavior upon impact loading and the hardness of the material can be found by hardness testers. These tests are quite important because they help engineers in making an informed decision about material selection and design.

Mechanical Testing Tools

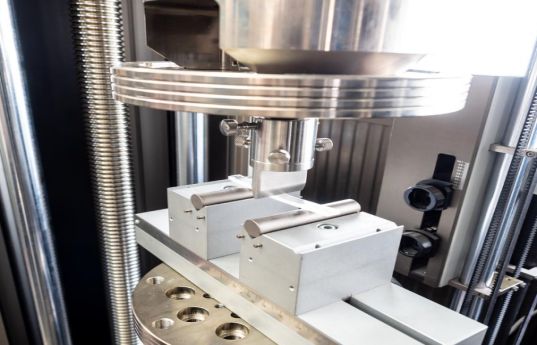

Mechanical testing of material can be done using various types of tools. The selection of tools can be made on the basis of the specific test. Universal testing machines (UTM), Fatigue Testing machines, Hardness testers, and Charpy impact testers are common tools used in mechanical tests. These tools enable researchers and engineers to apply controlled forces and analyze material responses.

Types of Mechanical Testing Methods

Various mechanical testing methods are available to find the mechanical behavior of materials that is found in various resins, plastics, and metal strength charts. Usually, geometry or shape of the material has nothing to do with their results. However, there are certain tests like tensile testing in which a change in the size of the specimen can greatly impact the properties of the material. Each method is unique in its approach and can be performed by using a specific machine and technique.

Mechanical Testing of Materials

Mechanical testing of materials is carried out in order to determine their physical and mechanical properties and also the reliability of the material in a specific application. It is important for you to do mechanical testing of materials because it provides information about the material’s ability to withstand load and environmental conditions in a proposed application.

Mechanical Behavior Testing and Manufacturing Properties of Materials

Mechanical properties of a material play a vital role in determining its behavior when stress is applied to it. It also accounts for their behavior during any part manufacturing or design process. Elastic modulus, ductility, hardness, and various measures of strength are such properties that are known as mechanical properties.

Mechanical Stress Test

In this process, the functionality of a material is determined when it is subjected to a sudden loading or sudden abrupt motion changes associated with service environments like product handling, shipping/transportation, aerospace, weapon firing, etc. These tests are discussed below:

Hardness Testing

The hardness of the material can be found by using the Hardness testing method. It is simply the resistance of the material to indentation or scratching. These tests are usually employed on material and there is no need to test the hardness of the final product. In this method, a small indenter is forced on the surface of the material to be tested. Then the depth of the indentation mark can be calculated by using any method. This depth measurement refers to the Hardness number. The higher the hardness numbers the smaller the penetration of the indenter mark.

Following are the various methods used for finding the hardness of materials

Brinell hardness Test

Brinell hardness test is the first accepted hardness testing method using an indenter. In this method, an indenter usually a steel ball is placed on the surface of the material, and then a load is applied on this ball for a small period of time. The indentation mark caused by the steel ball and load is then measured. Then by dividing the load by the indentation value give the Brinell Hardness Number (BHN). One of the great benefits of using the Brinell hardness test is that it does depend upon the surface roughness of the material. So, has to not worry about it.. This method is not suitable for welded joints and hard materials.

Vickers Hardness Test

The Vickers hardness test method is very similar to the Brinell hardness test. However, in the Vickers hardness test indenter in the form of a diamond pyramid is used. This method is best suitable for softer materials because it provides better accuracy. In the Vickers hardness test, the diamond indenter is placed on the material and then a specific load is applied to it to make an indentation mark. The Vickers hardness number can be calculated by dividing the force by the surface area of the indentation.

Rockwell Hardness Test

The Rockwell Hardness test has become standard for measuring the hardness test. This method is suitable for both soft and hard materials. In this method, according to a specific measured scale minor and then major load is applied on the material. Rockwell hardness number is then shown on the dial when the load is removed.

Knoop Hardness Test

The Knoop hardness test is almost similar to the Vickers hardness test. It also uses a pyramidal diamond indenter. This test is most suitable for thin and brittle materials which crack with other tests. The Knoop hardness test was mainly designed by the National Bureau of Statistics.

Shore Scleroscope Hardness Test

The Shore test is used to determine the hardness of materials by measuring the rebound height of a hammer which is dropped from a certain height onto the material.

Tensile Testing

Tensile testing is a material lab testing method that ensures material ability that it meets the minimum strength or ductility requirements. In this method, mechanical properties such as stress, strain, ultimate tensile strength, and yield point of the material are determined. In Tensile testing opposite loads are applied at the ends of the material and pulling it till it breaks. This testing is done by a tensile testing machine that is either hydraulic or electric. Usually, a Universal Testing Machine is used, which also gives the plot showing the strain-stress graph. Tensile test lab report (value and plot) helps in determining material’s strength and durability under specific loads.

Impact Testing

Impact testing helps in determining the toughness of the material. It enables the manufacturer to determine the amount of force required to break a material. This type of test is very important in assessing material behavior when subjected to accidents or collisions.

There are two types through which impact testing is done

IZOD Impact Strength Test

This is an ASTM standard impact testing. In this process, a raised pivoting arm is used to hit and break material. The energy was then calculated by using the height to which the pivot arm was raised.

Charpy Impact Test

This is also a material lab testing and is according to the ASTM standard test which involves the fracturing of material. In this test, a pendulum from a specific height is released.

Fracture Toughness

Fracture toughness measures a material's resistance to crack propagation. It enables the manufacturers to determine the amount of energy required to break material that contains an existing crack into two. Then by using data of values manufacturers can easily find the nature of the material i.e. brittle fracture and examine its grain size, case depth, etc.

Mechanical Properties Testing

The above-mentioned types of mechanical testing allow us to find the strength of materials. Now let’s dive into the various mechanical material properties testing methods that tell us about measuring a material’s intrinsic properties. The intrinsic properties of materials include such as stiffness, hardness, and corrosion resistance.

Creep Testing

Creep testing is also known as the stress-relaxation test. In this testing method, a material is subject to constant stress at a constant temperature. Then the plot of creep vs. time was obtained which tells about the creep rate.

Fatigue Testing

In this type of testing method cyclic loads are applied to the material then its behaviour is studied. These loads are applied axially, in torsion or flexure. Fatigue testing involves both mean and an alternating load on the material. As a result of these loads material experiences fatigue. The value of the data of the fatigue test can be found by using the S-N curve.

Non-Destructive Testing

Non-destructive testing involves the testing of material without causing any type of damage to it. These methods usually include ultrasonic, radiographic, and magnetic particle testing. Some of the common Non-Destructive Testing methods which are used in part manufacturing are:

Acoustic Emission Testing ( uses ultrasound to detect active cracks)

Electromagnetic Testing (uses an electric or magnetic field to detect flaws, measure thickness, or identify materials)

Leak Testing ( shows the presence of cracks or any outlet that can let a product leak)

How to Determine Tester Compliance

It is essential to guarantee that the staff who is dealing with all the mechanical tests must have the necessary experience and competence. There are various tests that help in measuring the tester’s talents and understanding of testing methodologies. These are discussed below:

Wiesen Test of Mechanical Aptitude

It is a type of comprehension test that is used to evaluate the ability of candidates to understand basic physical principles and their ability to use them in different conditions. The score of the candidate tells all about his ability. This includes how to use maintain, and repair equipment and machinery. This type of test consists of 60 questions which the candidate has to solve in 30 minutes.

Bennett mechanical comprehension test

It is a mechanical aptitude test based on mechanics. It was first developed by Pearson. It is used in various schools and companies as an indication for understanding and solving basic mechanical problems. It usually consists of 55 questions and 12 categories.

Mechanical Testing of Polymers

Nowadays, polymers are used in almost every industry. So it is quite important to understand its behavior under various loading conditions. However, their behavior is quite different from that of metal materials. The mechanical testing of polymers involves tensile strength, elongation, impact resistance, and other relevant properties.

Mechanical Engineering Test

It is an ability-checking test that is designed for mechanical engineers and is usually taken before employing them. In this mechanical analysis technique tests, any candidate's knowledge about various concepts, principles, and experience is assessed in various engineering fields.

Factors Influencing Mechanical Testing

There are a number of factors that affect the results of mechanical tests. Temperature, rate of loading, composition, and specimen preparation are factors that affect mechanical tests to a great extent. So in order to obtain more accurate results these factors must be considered while performing any mechanical test.

Why is Mechanical Testing Important

Mechanical testing has great importance in manufacturing as well as in part design processes. The benefit of carrying out the mechanical test is that it ensures the safety and economic feasibility. The main reason behind carrying out various mechanical tests is to understand the behavior of a material under a specific condition. They also ensure the material integrity. Therefore, mechanical testing is an important part of the following:

- Manufacturers

- Material Dealers

- Customers/ Clients

Tuofa Mechanical Testing INC: Test Materials and Parts

Are you tired of searching for a company that can provide you with a high-quality product made from tested materials? Then look no further. Shenzhen Tuofa Mechanical Testing, Inc. offers a broad range of mechanical testing services. These services cater to almost all industries requiring precise material strength assessment, characterization and evaluation. With modern machinery and equipment and experienced professional engineers, we ensure you accurate and reliable test results. Our all products are according to international standards and are also the most reliable.

FAQs about Mechanical Testing

What is the most widely used mechanical test?

The tensile test is the most commonly used mechanical test. In this strength and durability of the material are determined. This type of testing is carried out by using any tensile testing machine but usually Universal testing Machine is used. This includes applying opposite loads on the ends of the material and pulling it until it breaks.

When should Mechanical Testing be done?

In order to determine the working condition of material in any specified application Engineers and Manufacturers carried out mechanical testing of materials. So, these tests must be carried out during the design and development phase in order to ensure material suitability and reliability.

Who should be aware of Mechanical Testing?

As Mechanical testing plays a vital role in determining the workability of any material. The results of these tests will greatly influence the decision-making ability of engineers, researchers, manufacturers, customers, and quality control testing professionals. They must be well aware of the mechanical testing of materials before making any informed decisions.

How can it be tracked?

The Mechanical testing tracking process can be done by comprehensive documentation, reports of tests, and quality assurance processes. A certificate such as a mill test certificate (MTC), also called a mill test report (MTR), is an example of a document that certifies a product's chemical and mechanical properties.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is Deburring: 6 Tips for Deburring Metal

What is Deburring: 6 Tips for Deburring Metal