Stainless Steel 304L/1.4307: Everything You Want to Know

May 28,2024

May 28,2024

304l is an austenite stainless alloy. The composition of this low carbon stainless steel includes different metals. These are like chromium and nickel along with molybdenum. 304l has enhanced toughness and corrosion protection. Ductility is excellent in this grade which makes it demanding for applications for welding, pressing, and drawing. Food processing and chemical industries use stainless steel 304l very often due to high corrosion resistance. Construction and offshore applications are also common for this material. This article will highlight the main properties of 304l grade.

What does 304L Stainless Steel Mean?

304L is a variant of 304 grade. It is a low carbon stainless steel. 304 contains 0.08% carbon while 304l has 0.03% carbon, ‘L” in 304l denotes “very low carbon content.”

Is 304L stainless steel magnetic?

No, 304l is nonmagnetic in nature. But some cold working operations like bending or deforming makes the 1.4307 grade slightly magnetic. The degree of magnetism is very low. Actually, cold working first makes the steel to get free iron particles. These particles convert the crystal structure from austenite to martensite at some sites. This makes the 304l slightly magnetic.

304L stainless steel equivalent

The equivalent stainless steel 304l grades are:

|

Specs/trade names |

Grade |

|

EU |

X2CrNi18-9 |

|

EN |

1.4307 |

|

USA |

304l |

|

Japan (JIS) |

SUS304L |

|

France (AFNOR) |

Z2CN18 Z3CN18 Z3CN19-09 |

|

Sweden |

2352 |

|

Russia (GOST) |

04KH18N10 |

|

England (BS) |

304S11 |

Advantages and Disadvantages

Pros and cons of stainless steel 304l.14037 are as:

Advantages

- Corrosion resistance: 304L can resist corrosion from a variety of chemicals and harsh environments. It is mostly used in equipment and appliances due to its non-corrosive nature.

- High strength: it is suitable for making mechanical parts that require high strength properties.

- Wear resistance: wear and tear resistance are also comparable of this steel grade.

- Great formability: it is easily weldable and machinable due to being low carbon stainless steel and has higher ductility.

- Better processing: complex geometry and intricate shape can be made easily with good plasticity.

Disadvantages

- Easily scratchable: it is malleable and soft material. maintenance is required because it is easy to scratch. and it is necessary to pay attention during working due to low carbon stainless steel.

- Low high-temperature resistance: it performs best in room and low temperature. But high temperature resistance is low and can damage the steel due to its malleability and ductility.

What does 304L Stainless Steel Use for?

EN1.4307 grade has many commercial domestic applications. These are like:

- It is used in making beer brewing, wine making and mil processing purposes in the food processing industry.

- One of the common construction materials used in building bridges, roads, dams and canals.

- In marine environment, nuts and bolts, screws and fasteners are made of 304l.

- It is a common alloy for automobile and aerospace structural components.

- It is used to make heat exchangers in oil and gas industries.

- Chemical containers are made of EN1.4307 for transportation

- it is used to make kitchen appliances for household

Standard Specifications

The standard specs for 304L are as follows:

|

Standards |

304l |

|

ASME |

SA240 |

|

ASTM |

A666 |

|

ASTM |

A240 |

|

AMS |

5511 |

Cost

Compared to other grades, 304L is a cost-effective material. The alloying composition of EN1.4307 contains cheaper elements and does not contain expensive metal in higher quantity. The price of 304l varies with the thickness of bar for example, it is available in ¼” to 5”.

Corrosion Resistance

- 304l shows uniform corrosion resistance in all types of environments.

- 304l is mostly preferred for intergranular corrosion resistance of welds and for heat affected zones of alloys.

- 304l with 9-11%Ni has good corrosion resistance to mild organic acid.

- For oxidizing environment, 18-19% Cr in 304l performs good.

Carbon content

Standard 304 stainless steel has 0.08% carbon content. But 304l is known as low carbon stainless steel grade. It has 0.03% carbon content. L in the name refers to “low carbon content.”

Chemical Compositions

Chemical composition of En1.4307 is as follows:

|

Elements |

Percentage |

|

C |

0.03% |

|

Mn |

|

|

.inNi |

10% |

|

Cr |

19.5% |

|

S |

0.03% |

|

P |

0.045% |

|

Si |

1% |

Mechanical Properties

Mechanical properties of En1.3407 is as follows:

|

Mechanical properties |

Values |

|

Tensile strength |

75ksi |

|

Yield strength, 0.2% |

30ksi |

|

elongation |

40% |

|

Modulus of elasticity |

28psi x106 |

|

Hardness |

210HB |

Physical Properties

Physical properties of En1.3407 is as follows:

|

physical properties |

Values |

|

Density |

8000kg/m3 |

|

Melting point |

1450℃ |

|

Specific heat |

0.12 BTU/lb/ᵒF |

|

Thermal expansion |

17.2x10-6K |

|

Thermal conductivity |

16.2W.m/k |

|

Electrical resistivity |

0.062Ω.m |

Fabrication

304l must be fabricated with only tools dedicated to stainless steel grades. 304l is malleable and ductile. Therefore, it cannot be fabricated with other tools. For better results, work surfaces must be cleaned. To avoid cross contamination of 304l steel by corrosive elements, these precautions are essential. It will also protect the surface from discoloration.

Weldability

304l has exceptional weldability. It does not require post weld annealing for thin welded cross-sectional areas. Wels joints are created by considering two important points in 304l stainless steel and these are cracks must be avoided and corrosion resistance must be preserved.

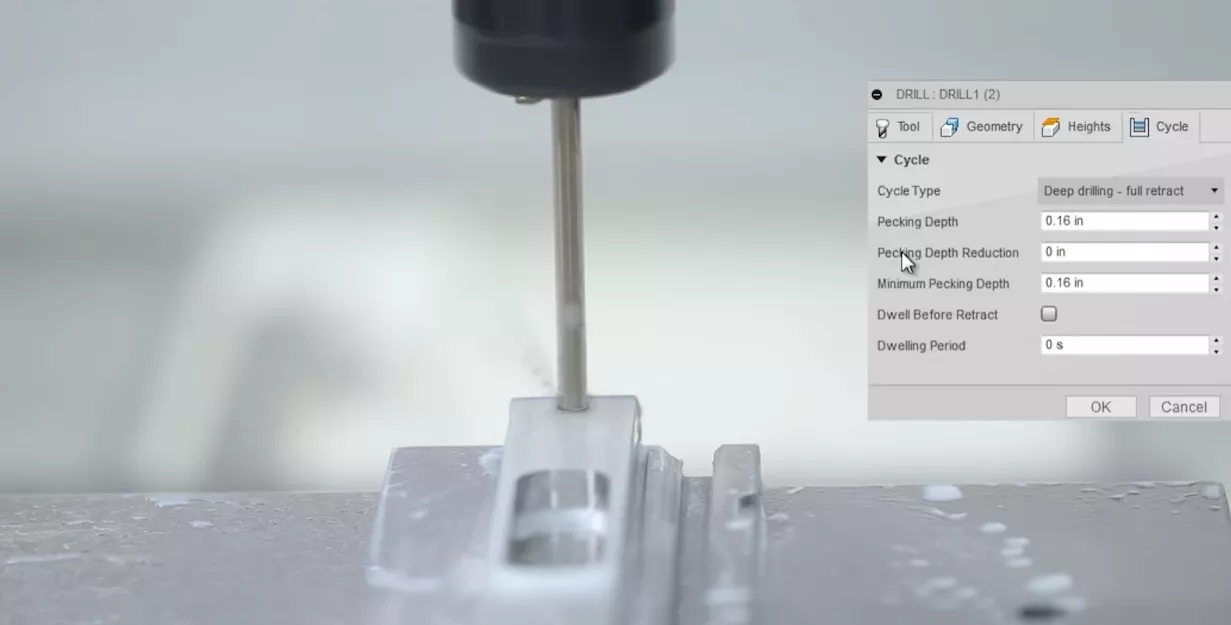

Machinability

During machinability. Chips are stingy and chips breakers are required. Work hardening of stainless steel 304l occurs rapidly. It is essential to use heavy positive feed, Sharp tools and rigid setup.

Heat Treatment

Hardness is affected in 304l by heat treatment. Solution treatment or annealing are required normally to have good formability. This is carried out by rapid cooling after heating till 1120℃.

Is 304L Stainless Steel Annealed?

Yes, 304l is annealed. Annealing resets the properties of 304l stainless steel such as tensile strength, yield strength, elasticity. This helps in preparing metal for rolling operations. 304l in annealed conditions offers good formability.

Important Factors to Consider When Choosing Custom 304L Stainless Steel Parts

It is challenging to choose the right stainless-steel grade for any project. But it can be done by understanding the properties of stainless steel. The selection of material is mostly done by considering the application of alloy. there are important factors to be considered when selecting 304l grade for any project:

- Corrosion resistance

- Oxidation resistance

- Forming

- Strength

- Ductility and malleability

- Working environments

- Service temperatures.

Summary

304L stainless steel, known for its low carbon content, enhances corrosion resistance and makes it suitable for welding and high-temperature environments. Widely used in industries such as food processing, chemical, construction, and marine engineering, 304L stainless steel offers excellent corrosion resistance and formability. Its key features include a non-magnetic nature in its annealed state, good tensile and yield strength, and ease of forming and welding. The economic benefits of using 304L stainless steel make it a preferred material for many industrial applications, perfectly complementing the high-quality machining services provided by Machining Quote.

As a leading Chinese supplier specializing in machined parts, Machining Quote offers you top-tier CNC machining services. Choose Machining Quote for reliable and expert CNC machining services, leveraging the advantages of 304L stainless steel to deliver superior results.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Comprehensive Guide to 7075 Aluminum: Properties, Applications, and Machining Tips

Comprehensive Guide to 7075 Aluminum: Properties, Applications, and Machining Tips