Comprehensive Guide to 7075 Aluminum: Properties, Applications, and Machining Tips

May 28,2024

May 28,2024

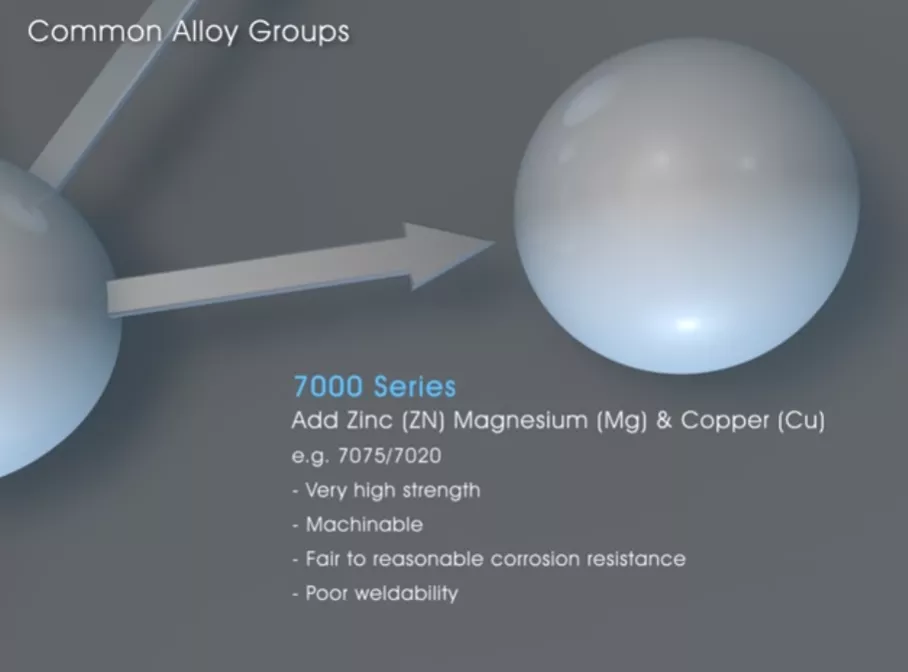

Aluminum alloys are commonly used in aircrafts. Because they have high strength. 7075 Aluminum from 7000 series also has high toughness. Its strength is excellent under highly stressed conditions. This alloy is comparable to steel. And it has most of the applications in supporting structures. When this alloy is heat treated like ageing and temper, its properties are further improved. More information about its properties, application and important points while selecting 7075 Aluminum are discussed below.

Understanding 7075 Aluminum Alloy

7075 Aluminum was developed in the 1930s. A Japanese manufacturer had an aim to build aircraft with lighter weight. 7075 bars are commercially used grade to build airplanes. L95 is the aerospace equivalent grade. It is commercially used in nuclear and military equipment to make highly stressed structural parts. 7075 Aluminum is used where corrosion resistance is not the priority.

Composition and Key Elements

7075 Aluminum composed of aluminum with zinc and magnesium and copper as alloying elements. Small amounts of iron, manganese, chromium, titanium and silicon are also added. Its high strength to weight ratio and goof fatigue strength are very appreciated in aerospace industry,

The primary alloying element zinc improves strength. Magnesium and copper increases precipitation hardening. Chromium increases corrosion resistance. while all the other elements are impurities. The combination of all these alloying elements increases strength, with moderate, machining, weldability, corrosion resistance and formability of 7075 Aluminum. Compared with 2024 or 6061 Aluminum, it has great strength in highly stressed applications.

|

Alloying elements |

Percentage |

|

Zn |

6% |

|

Mg |

3% |

|

Cu |

2% |

|

Fe |

0.5% |

|

Si |

0.4% |

|

Mn |

0.3% |

|

Cr |

0.28% |

|

Ti |

0.2% |

|

Al |

Balance |

Mechanical Properties of 7075 Aluminum

Tensile Strength and Yield Strength

7075 Aluminum is known for its high strength. Its tensile strength is 570MPa. It also has good fatigue strength and machining properties. But it is heat treatable which improves its all the other properties. It can process thorough forging, rolling, extrusion, drawing and can be in powder, bars, and plates forms. Hardness can be improved by heat treatment by aging and temper up to 190HB but decreases ductility. Fatigue strength is 40% better than alloys in the series. Dimensional stability is good and eases the strain hardening.

Enhanced Properties Through Heat Treatment

Solution annealing carried out at 900ᵒF for 2hrs with water quenching. Precipitation hardening then carried out at 250ᵒF for 24hrs. heat treatments are given to homogenize the alloy properties. It softens the material during hot and cold working which eases the foaming and machinability of alloy. Ageing and annealing treatment of alloy 7075 reduces the micro segregation and improves the mechanical properties by aging and tempering.

Under Various Tempering Conditions

Mechanical properties of aluminum 7075 are different for temper heat treated 7075 by aging.

|

Heat treated alloy |

Tensile strength |

Yield strength |

Elongation |

|

7075-O |

241Mpa |

103MPa |

17% |

|

7075-T6 |

572MPa |

503MPa |

11% |

|

7075-T651 |

524MPa |

469MPa |

12% |

|

7075-T7351 |

572MPa |

503MPa |

8% |

|

7075-T736 |

496MPa |

455MPa |

10% |

|

7075-T7 |

505MPa |

435MPa |

13% |

|

7075-RRA |

510-540MPa |

430-480MPa |

5-11% |

Key Applications of 7075 Aluminum

Specific components made from 7075 aluminum in aircraft.

705 is used to make space shuttle nozzles and external beams in internal areas. It is used to make forward and aft- skirts. It is also used in interstage of SII, and 2nd stage of Saturn V. The first mass production of 7075 was for the Mistubishi-A6M-Zero fighter. The flexibility if this aircraft was excellent and has higher strength as compared to other aircrafts.

Benefits of using 7075 Aluminum in aerospace engineering

7075 Aluminum rods have less fatigue strength than steel rods, but they are lighter in weight than steel parts, this results in low mechanical stress during working especially in engines which work with high RPM condition.

Automotive: Role in high-performance parts

7075 Aluminum is used in transportation in marine, and automotive industries. It is used in making equipment for rock climbing, bicycle, skating frame and airframes. Chassis parts are also made of it.

Sporting goods and defense: Diverse applications of 7075 aluminum

7075 Aluminum is used for making rifles for military and civilian markets. 7075-T6 is used to make upper and lower rifle receiver. extension tubes are also made of aging or temper aluminum alloys.

Challenges and Solutions in Machining 7075 Aluminum

Common Machining Issues

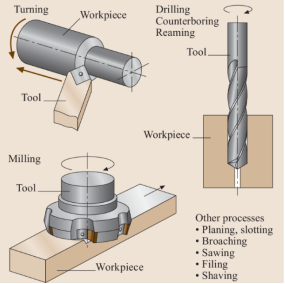

Common issues occur in machining of aluminum alloys are as:

- Warps: it is the distortion of workpiece in machining. The cause of warping is the generated heat, applied forces in machining. The properties of aluminum alloys also play a role in it.

- Cracks: cracks are formed due to generated heat in machining. It is also because of the presence of impurities in aluminum alloys.

- Burrs: these are the small sharp edges left after machining. Their cause is less sharp cutting tools used in machining.

- Undercuts: this occurs when excessive material is removed during machining and form deep cuts. This is due to using larger cutting tools than workpiece in machining.

Workability challenges due to high zinc content

High zinc content increase strength by precipitation hardening in aluminum alloys. But it also makes the alloys prone to cracking while machining. To manage its hardness and wearing, carbide tips and diamonds tips are used in machining.

During anodizing, high zinc in 7075 Aluminum can reduce the visual appearance and aesthetics. This results in poor alloy finishing.

Strategies to mitigate common issues during CNC machining

The issues that occur in machining can be avoided by following good practice. These are:

- Use of shar cutting tools

- Use of right feed rate

- Use of correct speed of tool

- Tightly secure the workpiece

- Thoroughly inspect the workpiece for dislocation and defect

7075 Aluminum Machining Tips from Tuofa

Using 7075 Aluminum, Tuofa CNC machining services offer a range of services and manufactured products of CNC machined, tuned, milled, lath stamping and sheet metal. Tuofa strictly controls the precision in machining and ensures quality of complex and intricate parts. Highly skilled labor and the most advanced equipment in Tuofa results in high quality machining products. Tuofa makes sure:

- To use coolant to remove heat from workpiece to avoid burrs and cracking.

- Use lubricant to reduce friction in the workpiece.

- Use compatible cutting tools with workpiece.

- Selecting the right machining process.

- Optimizing machining parameters.

- Inspection of workpiece to avoid defects.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is AISI 4140 Material? Advantages and Properties

What is AISI 4140 Material? Advantages and Properties