Snap Fit Joints: 5 Tips for Fasteners Design Guide

Sep 21,2023

Sep 21,2023

Snap Fit Joints: 5 Tips for Fasteners Design Guide. Introduction: Design engineer have many options to fasten the elements by different ways but if structure or client need specific method to join then it is not easy job to do it. Because you have to be specific in one method of joining with consideration of loading bearing, material selection, long life and reliable fastening joint. Thus it is necessary to stick on specific joint of snap fit in many cases due to aesthetics, machining joints, seamless connection and mechanical fasteners.

What is Snap Fit?

It is joint design to fasten the two elements in structure with temporary deformation in male part so that it can hold counterpart in permanent way and dis assemble whenever it needs. Snap fit fasteners have application in plastic products due to their aesthetic look, no need of thread mechanism and easy clamping action with low force by general users. Snap fit joints are the best alternative of screws, welds, latches and rivets with the flexible option of connect and disconnect in easy / user friendly manner.

Types of Snap Fit Joints

They have types as per joint configuration, force exertion and area of working with fastening mechanism for different machining joints / mechanical fasteners. There are major three categories:

1. Cantilever Joint

2. Annular Joint

3. Torsion Joint

In cantilever joint one cantilever beam works for seamless connections but in case of spring action with same cantilever new category of torsional joint type is the result. While annularsnapjointistheremovablefitof thecircumferencearea withmaleandcounterpart members inline of closing and opening action.

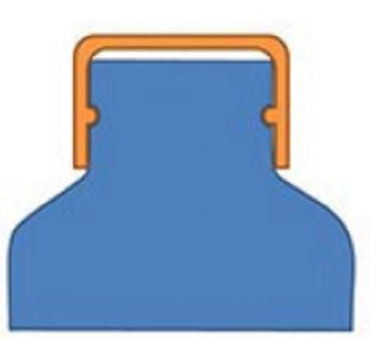

Annular Snap Fit Joint

In this nap fit joint sizes are in the range of circumference of the joint area or connection because whole of the closing and opening mechanism need to operate within that area. Otherwise if patches work all around the circumference then annular snap joint changes its category from this design to cantilever type of same class. Another important advantage of this joint is that it can bear large force due to long area of contact and low stress value distribution in the circumference region.

Figure.No.2 shows annular snap joint.

Figure.No.2.Annular Snap Joint.

How Do Annular Snap Fit Joints Work?

Their work is to temporary deform the locking part during insertion in counterpart to make firm connection by shear resistance against the locking wall of female member. In order to unlock the whole system you have to make hand force on the specific point so that removable snap fit make its way to unlock it. Complete procedure is also present in snap fit design guide of specific product for safe, easy and user friendly operation of product during lifespan.

Annular Snap Joint Examples

Common examples of this kind of snap fit joint are Ballpoint cap, Bottle cap and bottle base with flange, they have application in those places where complete circumference should be in sealing position.

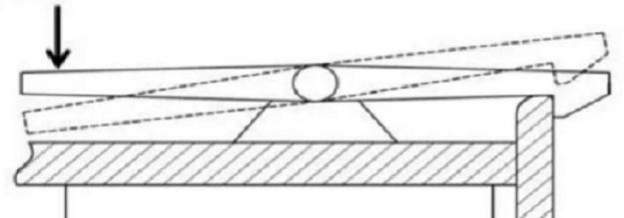

Torsion Snap Fit Joint

It is plastic snap fit joint to lock the male part in counterpart with deformation of material and production of torsion in shaft spring so that locking mechanism has firm connection. It is also removable snap fit because it has the option to lock and unlock the mechanism is same way of cantilever snap fit joint but extra addition of spring torsion is the addon feature of safety. Latch system can work with ease of handling and user friendly atmosphere to work with.

Figure.No.2 shows torsion snap joint.

Figure.No.2 Torsion Snap Joint.

How do torsion Snap Joints work?

It works by making spring action to lock the mechanism of male part and after that same spring action can lose itself to unlock the same part. In realtime situation same spring goes to torsion action to absorb the torsion force of locking mechanism and have stress in radial direction below the yield point.

Torsion Snap Joint Examples

Rocker armin combination with cantilever and shaft rod is the perfect example of torsion snap joint example because its shaft have spring to absorb the torsion force. And it can lock and unlock the structure with little use of force to remain user friendly in operation.

What are Torsion Snap Joints Used for

They have application in place where there is requirement to have cantilever armsnap joint but with the use of little force to lock and unlock the part. That is why these joints have massive application in place of security box with separate locking system.

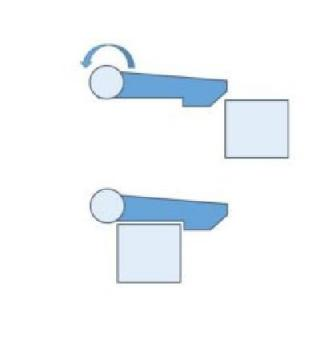

Cantilever Snap Fit Joint

It is common concept in snap fit design guide because it has common feature and advantage of snap fit joints, like in case of annular and torsion snap fit joints some extra add on features are also present. But here no extra amount of force and complete circumference contact is the need of snap fit design guide. Cylinder snap fit joint can also do the same work but in case of that it is very difficult to offer easy solution for you to lock and unlock the snap fit joints with common practice.

How do Cantilever Snap Joints Work

It can work by just making click on the snap fit fastener and then insert it into the female counterpart so that shear action can hold it with good grip and resistance mechanism of locking wall.

Figure.No.3 shows cantilever snap joint.

Figure.No.3.Cantilever Snap Joint.

Cantilever Snap Joint Examples

Plastic mating surface can have easy and user friendly locking and unlocking system for use in field with this type of joint because of simple joint design. They can have different types of snap fit sizes because here no depending variables are present in structure of locking and unlocking mechanism. Zip bag locking and mobile back cover plastic snap fit design are common examples.

What are Cantilever Snap Joints used for?

They have application where need of temporary locking and unlocking is present becauseforlongtimelockingsystemtorsionsnapfit joints or cylindersnapfit arecommon method to do it.

Table.No.1 shows different relations for Cantilever Snap Joint.

| Parameter for Cantilever Snap Joint | Relation of Snap Joint |

| Stress for Cantilever | Sigma max. = (Ymax.Mmax)/I |

| Strain for Cantilever | e.max=M/(Z.E.) |

Table.No.1.Parmater for Snap Joints.

How to Design Snap Fit Joints: Metal & Plastic Snap Fit

For this kind of plastic and metal snap fit design there are some basic principles to follow otherwise design may work but you can say it is not reliable one. And these basic principles are:

1. Uniform thickness reduction form one side of snap fit joints to its other extreme part.

2. There is no large sharp radius is present in profile.

3. Avoid any stress concentration area in whole profile.

Click here for precision machining and design of product like snap joint.

5 Tips for Designing Durable Snap Fit Joints

Theremanyfactorwhichdecidethat whichdesignofsnapfit jointis moredurable, reliable, long life and high strength but here are 5 tips to have durable snap fit joints:

Radius Ratio

Ratio of radius of cantilever start to thickness of arm should be greater than 0.6 because it is that design factor which reduces the stress concentration.

Radius Value

Absolute radius value of cantilever arm should be greater than 0.015 inch.

Length of Cantilever Arm

Length of cantilever arm should be in tapper position because in this way it can have less strength and more flexibility at end.

Rectangular Cantilever

Rectangular cantilever especially in case of metal snap fit design have greater moment of inertia and more strength to bear the external force.

Design Minimum Strain

Minimum strain is the best design factor in snap fit joints because in this way it can have more energy in it without fracture.

Table.No.2 shows materials for snap joint.

| Materials | Class |

| ABS | Plastic |

| Nylon | Plastic |

| Acetal | Plastic |

| PET | Plastic |

| PBT | Plastic |

Table.No.2 Materials for Snap Joint.

Common Issues with Snap Fit Design

One of the major issue with these joint is that they can fail in field at low strength due to low stress bearing capacity, because over stretching is possible in field due to presence of largestrain factor. Second factor is that if it fails in service then whole part is of no use for remaining span of life, third factor is that sometimes it is difficult to disengage it even with large force. Another important factor is that undercut and creep factor can damage the piece before its design life and at low stress level of simulation.

What are the Advantages of Snap Fitting with CNC Machining?

Precision is only possible by CNC machining process especially in case of metallic snap fit joint because in this way you can have dimension with accurate tolerances to accommodate locking and unlocking system. Otherwise fabrication and welding technique cannot give accurate result for same kind of system and job with tolerance values.

Click hereto get instant quote of precision CNC machining of Snap fit joints design and fabrication.

Advantages of 3d Print Snap Fit Joints:

In this you need only 3d simulation file may in .Stl format to draw the 3d print of job with precision and accurate dimension without involvement of CNC machining, welding, bending and fabrication technique. Even no mold work is the need for the same process due to one process facility of 3d printer and its methodology with layer wise accumulation of material.

Disadvantages of Snap Fit Joints

They cannot bear extra or higher force whenever it works in field of application due to low strength material with very low thickness to accommodate the flexibility of cantilever arm. That is why these joints are not durable one in joint design guideline literature due to low force bearing capacity, limitation of material and dimensional limitation.

How to Install and Maintain Snap Fit Joints

Installation of these snap joints is easy and user friendly because:

1. In this process you have to only press the specific portion of the product 2. Until it can go inside the counterpart.

3. Then locking system can hold it forrest of time.

4. You can allow it to stay in this position may be for weeks or months without losing strength and locking mechanism.

One of the important aspect for maintenance of the same system is to design whole system in such a way that clicking part of it does not receive the force to bend itself. Because if it gets the force then it will open the locking system in that position where its design does not guide about it.

Applications of Snap Joints

There are many applications for these types of joints because of simple, ease and aesthetic nature of this option but major applications are for Zip bag lock, Mobile back cover, Pen cap, Bottle cap and Latch lock for tool box. They have application in place where design need does not allow the use of any screw, rivet and welding joining method due to limitation of space, interference and reliable opening / closing mechanism. Plastic products have lot of different kinds of snap joints due to limitation of screws, rivet and welding in them and these products need re-usable connection also.

What can Tuofa do for Your Snap Fit Joints Project

Tuofa has experience team of design engineers for design of snap fit joints with ISO 9001 certification, so that snap fit joints can work in remaining span of life with reliable operation.

It can provide fabrication of same joints with modern production facility and quality control during the mass production of same, so that no negative feedback is available in general market.

Custom product for same joint design is the specific expertise area of Tuofa China becauseitcandesignsnapfit jointas per yourneed, dimension,forceandmaterial.

Major contribution of this design is that Tuofa can include all the custom needs with economical material and product cost, sot that product can compete in market price. For more information please visithttps://www.tuofa-cncmachining.com. Or send part drawings to info@tuofa-cncmachining.com, Our engineers will give you the best advice.

FAQs about Snap Fit Joints

What are the Parts of a Snap Fit Joint?

Different parts which makes it are Protrusion of end lock, Groove at base, complete male component of locking arm, Hook and Female counterpart cavity part. These parts have separate design to counter stress concentration in each of area and to avoid force build up in small area of stress gradient.

What material are best used to manufacture annular snap joints?

Those plastic material which are thermoplastic in nature, flexible and can withstand force of bending without rupture are the best possible examples of annular snap fit joints, thus it is helpful to seal the all circumference area with this joint methodology.

What materials are best used to manufacture cantilever snap joint?

ABS or Nylon type material are best materials to make cantilever snap joint because of bending strength, moment of inertia and less stress concentration in area of base groove. Another important aspect of using same material is high fatigue and creep strength to incorporate all weather feature use in main product, otherwise temperature gradient can make stress rupture in it.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

CNC Production Machining Guide | 5 Things to Outsource Production

CNC Production Machining Guide | 5 Things to Outsource Production