What Are The Types of Parts Marking?

Jul 17,2022

Jul 17,2022

Why Parts Marking Services

In the process of designing parts, everyone likes to cover their own brand LOGO on the surface of the parts. In this way, brand awareness can be increased. In the manufacturing industry, how the LOGO is applied in a product can better reflect the image of the brand. The so-called details determine success or failure, and the treatment of LOGO is the details of the details when designing products. Product designers will consider whether the location, style and process of the LOGO are suitable for the purpose when completing the product design.

How to choose a part marking service

As an excellent designer, you need to understand the processing technology of LOGO. A good product can drive a good brand, and a good brand assists a good product, and the two complement each other. The best-selling products will undoubtedly add a lot to the brand, so the treatment of the brand LOGO is particularly important. Mastering the processing method of LOGO can definitely play a finishing touch when doing product design. Different processing methods will also bring different emotional expressions and transmission of quality spirit.

Tuofa CNC Machining Parts Manufacturer Now Introduces Three Part Marking Services

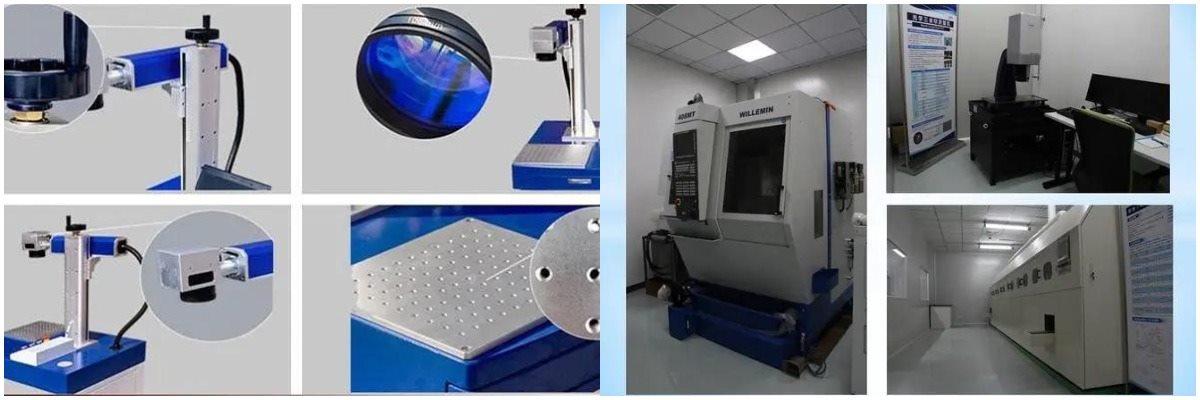

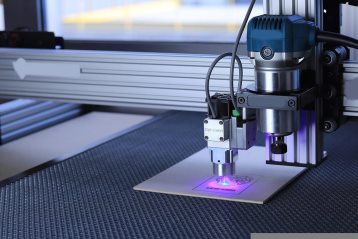

1.Laser Marking LOGO

The principle of Laser Marking LOGO

Custom laser marking parts is a manufacturing service that sheet metal manufacturers excel at.

The basic principle of laser marking is that a high-energy continuous laser beam is generated by a laser generator, and the focused laser acts on the printing material to instantly melt or even vaporize the surface material. By controlling the path of the laser on the surface of the material, the formation of Graphical markup required.

Laser marking is characterized by non-contact processing, which can be marked on any special-shaped surface without deformation and internal stress of the workpieces. It is suitable for marking materials such as metal(Aluminum, Steel, Stainless Steel, Brass, Bronze), plastic(POM, ABS, PC), glass, ceramics, wood, and leather.

Lasers can mark almost all parts (such as pistons, piston rings, valves, valve seats, hardware tools, sanitary ware, electronic components, etc.), and the markings are wear-resistant, the production process is easy to automate, and the marked parts are less deformed.

The laser marking machine adopts the scanning method for marking, that is, the laser beam is incident on two mirrors, and the mirrors are rotated along the X and Y axes by the computer-controlled scanning motor. The laser beam is focused and falls on the marked workpieces, thereby forming a traces of laser marking.

The advantage of Laser Marking LOGO

The focused ultra-fine laser beam is like a tool, which can remove the material on the surface of the object point by point. Its advanced nature is that the marking process is non-contact processing without mechanical extrusion or mechanical stress, so it will not damage the processed items. Due to the laser focused size is small, the heat-affected area is small, and the processing is fine. Therefore, some processes that cannot be achieved by conventional methods can be completed.

The "tool" used in laser processing is a focused light spot, and no additional equipment and materials are required. As long as the laser can work normally, it can be processed continuously for a long time. Laser processing is fast and inexpensive. Laser processing is automatically controlled by computer, and no human intervention is required during production.

What kind of information the laser can mark is only related to the content designed in the computer. As long as the artwork marking system designed in the computer can identify it, the marking machine can accurately copy the design information on the appropriate carrier. So the function of the software actually largely determines the function of the system.

2.CNC engraving LOGO

2.1The principle of CNC engraving LOGO

CNC mechanical engraving LOGO is the engraving completed by computer numerical control machine. Use a tool to remove material from the surface of the workpieces to engrave a pattern or LOGO.

The advantage of CNC engraving LOGO

Compared with laser marking LOGO, the CNC engraved LOGO is durable and wear-resistant. Parts suitable for outdoor use such as bicycle parts, motorcycle parts, solar parts and so on.

3.Silk screen LOGO

The principle of silk screen LOGO

Screen printing is the most common surface treatment process. It uses the screen as the plate base and uses the photosensitive plate-making method to produce a printing effect with graphics and text. The technology is very mature. The principle and process of silk screen printing are very simple, that is, the basic principle that the mesh of the logo part is transparent to the ink, and the mesh of the non-logo part is not transparent to the ink.

When printing, pour ink on one end of the screen printing plate, apply a certain pressure to the ink part of the screen printing plate with a scraper, and move to the other end of the screen printing plate at the same time. The ink is squeezed onto the substrate by the scraper from the mesh of the logo part during the movement.

The advantage of silk screen LOGO

Low cost and quick effect. Screen printing can be produced by mechanization or manual operation. The equipment and material costs required by this printing method are lower than other printing methods, and the plate-making method and printing method are also relatively simple.

Strong adhesion and good ink adhesion. Due to the characteristics of the screen plate, the ink is directly attached to the surface of the substrate through the screen holes.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Custom CNC Machining for the Medlcal Industry

Custom CNC Machining for the Medlcal Industry