2025 Trends of Custom CNC Parts Services

Jul 21,2022

Jul 21,2022

Custom CNC machining requires the creation of components that do not exist elsewhere. It may be any CNC machining, such as CNC turning, CNC milling, and EDM, that a firm is capable of providing. A bespoke component might be anything as essential as a gear. However, you may want the equipment in a nonstandard size or material, or it may be a novel innovation that suppliers do not currently have, necessitating bespoke fabrication of the item. Selecting custom CNC machining parts and a CNC machining parts supplier is essential.

Here we will discuss everything; let’s start:

What are custom CNC machining parts?

The CNC machining process includes custom machining. Machinists may use several CNC machining forms to manufacture a new component in custom machining. Custom machining is required when a particular item is unavailable at the machine shop, and they may then use CNC machining services to make the component. When a common item has a unique need, custom machining is necessary. And bespoke machining is not limited to the production of small things. However, it is also possible to design significant portions with several characteristics. These components are tailored to match a particular project.

Why should we custom CNC machining parts?

Unlike human labor, CNC machines can operate continually without deterioration in quality. Other benefits of using this manufacturing technique include flexibility, safety, and the lack of the need to take a break from work.

Production on Time CNC machining entails eliminating raw material blocks until the required form is achieved. A computer regulates the manufacturing machine, ensuring the speed is kept within a specific range.

Given that the device is programmed to follow precise protocols, it is unlikely that a mistake would occur, necessitating a repetition of the operation. Furthermore, a CNC machining firm comprises knowledgeable CNC engineers with expertise in making varied components, resulting in a speedy turnaround.

High Precision and High-Quality Parts

CNC machining enables the manufacture of demanding applications. Even with tiny diameters and unique features on a component, CNC production's high accuracy capabilities assure you receive exactly what you need. Furthermore, the manufacturing machine enables the constant fabrication of comparable components until the final item you purchase.

Affordability

When a product is a one-of-a-kind, it isn't easy to locate it in several shops, and it is pricey if you find it in any shop. Opting for bespoke machining removes the chance of overspending while still receiving a high-quality result.

What are the technical requirements for CNC machining suppliers?

CNC machining is a standard process for producing components and products from sheet metal or plastic using several techniques such as forming, tapping, milling, and so on. CNC machining provides high accuracy, maximum strength, and tight tolerances for the components. CNC machined components are in high demand across industries due to machining flexibility and technical improvements. Selecting a CNC machining provider may seem simple, but it entails more than a list of skills or specs. The following things should be considered while making a choice.

- Product precision and quality: When choosing a CNC machining provider, quality is one of the most crucial factors to consider. Other qualifications for the top CNC provider include high-density designs, quick production lines, strong conductivity, durability, and much more.

- CNC Pricing: The cost of CNC machined components is determined by design complexity, tooling requirements, and the number of machining techniques used, among others. This must be examined about your budget and its influence on the overall cost of the product. The service provider must choose the appropriate methods and approaches to reduce high prices.

- Experience in the Industry: One of the most crucial aspects distinguishing the average CNC provider from the top is their overall market presence and the types of clientele with whom they have worked. The industrial expertise of CNC machining providers demonstrates their capacity to adapt and develop in the face of modern technologies.

- Delivery on time: While accuracy and quality are vital, the supplier must also provide quick turnaround times. As a result, ensure that the CNC machining provider you contact has an excellent track record of on-time delivery without sacrificing quality.

- Customer Service: To develop and improve the number of customers, every CNC machining provider must provide excellent customer service. They should also be available for technical talks, answering questions, and sharing ideas.

Which CNC machining parts supplier should be selected for custom CNC machining parts?

You are not alone if your business relies heavily on CNC-turned components, a crucial aspect of every industry in today's contemporary society. You may demand one-time production of features or a continuous supply of the parts. Here are a few pointers on how to ensure you obtain the finest CNC machining services and features from a reputable CNC manufacturer:

Customer Support

Customer service provided by your manufacturer is equally critical to the client pleasure you will supply to your customers and your performance. It is essential to have proper engagement as well as flexibility with your provider.

Ability to provide Tuofa CNC machining components

Your selected component manufacturer must agree to offer you one that meets your specific needs without compromising quality or service.

Time Efficiency

You must provide your customers on time to thrive, and if you fail to meet your deadline, your consumers will go elsewhere for their components. Inquire about the supplier's track record and timeliness. A corporation with an excellent track record would never hesitate to give its details. Time performance is more critical than attempting to save money; therefore, seek the finest component supplier and a manufacturer with whom you can establish a long-term and personal connection. It may make a substantial difference between the success and failure of your industry, as your choice of CNC machining business is critical. It would help if you relied on the professionals you know will offer you the most excellent services available in the future.

Quality Assurance

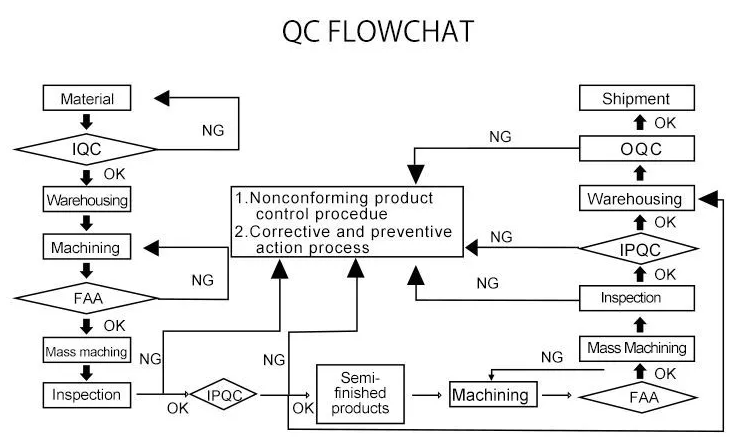

Many suppliers have a quality control department, and you may request essential documents to ensure the efficiency and quality of their components. Along with performance information, accessible quality control records must be provided, enabling you to truly understand the organization being evaluated for custom CNC machining parts.

Tuofa CNC machining parts supplier ability

Tuofa CNC machining parts supplier customers depend on Tuofa is high-speed capabilities to satisfy contract manufacturing demands in their continually changing sectors. Companies can rely on our professional team to provide accuracy, knowledge, technology, and exceptional customer service. Their in-house engineering analysis, precise inspection, and quality control services assure our goods reliability; quality control is more of an activity than a word.

Tuofa CNC machining parts provider with Multiaxis CNC machining centers and inspections with CMM and more precise tools. We are a cost-effective solution due to our use of cost-effective materials and cost management throughout the process. You may get a free online quotation if your material is uploaded. A short lead time guarantees that the items arrive on schedule. Their CNC machines can handle complex tasks such as tiny radius cuts and tapped holes while maintaining a high degree of quality.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Why Sheet Metal Stamping Computer Case?

Why Sheet Metal Stamping Computer Case?