What is a CNC Aluminum Keyboard? Tuofa CNC Machining China

Jul 30,2024

Jul 30,2024

In recent years, the mechanical keyboard community has seen a surge in popularity for custom-built keyboards. Among these, CNC aluminum keyboards have garnered significant attention. They are known for their durability, aesthetic appeal, and customizable features. But what exactly is a CNC Custom Mechanical Keyboard, and why are they becoming the preferred choice for many enthusiasts? This article delves into the intricacies of machining keyboard cases. It explores their manufacturing process, benefits, and why they stand out in the world of mechanical keyboards.

Understanding CNC Aluminum Keyboards

A CNC aluminum keyboard is a mechanical keyboard. Its main components, such as the case and sometimes the plate, are machined from a block of aluminum. This is done using CNC (Computer Numerical Control) technology. CNC Machined is a manufacturing process. In this process, pre-programmed computer software dictates the movement of factory tools and machinery. This process is used to control a range of complex machinery. These include grinders, lathes, mills, and routers. With CNC machining, a three-dimensional cutting task can be accomplished in a single set of prompts.https://www.tuofa-cncmachining.com/

The CNC Machining Process

The process of creating a CNC aluminum keyboard involves several key steps:

Design and CAD Modeling

The first step in creating a CNC aluminum keyboard is designing the keyboard layout and case using CAD (Computer-Aided Design) software. This model includes precise measurements and specifications for every component of the keyboard.

Material Selection

High-quality aluminum blocks are chosen based on the desired strength, weight, and finish of the final product. Aluminum is favored for its durability, lightweight nature, and resistance to corrosion.

Programming the CNC Machine

The CAD model is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program provides the instructions that the CNC machine will follow to cut and shape the aluminum block.

Machining the Aluminum

The aluminum block is securely fastened into the CNC machine, and the machining process begins. The machine uses various tools to cut, drill, and mill the block into the desired shape. This process can take several hours depending on the complexity of the design.

Finishing Touches

Once the machining is complete, the keyboard case is polished, anodized, or coated to achieve the desired finish. Anodizing not only enhances the appearance but also adds a layer of protection against scratches and corrosion.

Assembly

The final step involves assembling the keyboard. This includes installing the switches, keycaps, and other components. This is often done by hand to ensure precision and quality.

Benefits of CNC Aluminum Keyboards

CNC aluminum keyboards offer several advantages over traditional plastic keyboards and other types of mechanical keyboards:

|

Benefit |

Description |

|

Durability |

Strong and resistant |

|

Aesthetic Appeal |

Sleek and professional |

|

Customizability |

Highly customizable |

|

Typing Experience |

Stable and satisfying |

|

Thermal Management |

Excellent heat dissipation |

Durability

Aluminum is a robust material that can withstand significant wear and tear. CNC aluminum cases are less likely to crack or break compared to plastic cases. This makes them ideal for long-term use.

Aesthetic Appeal

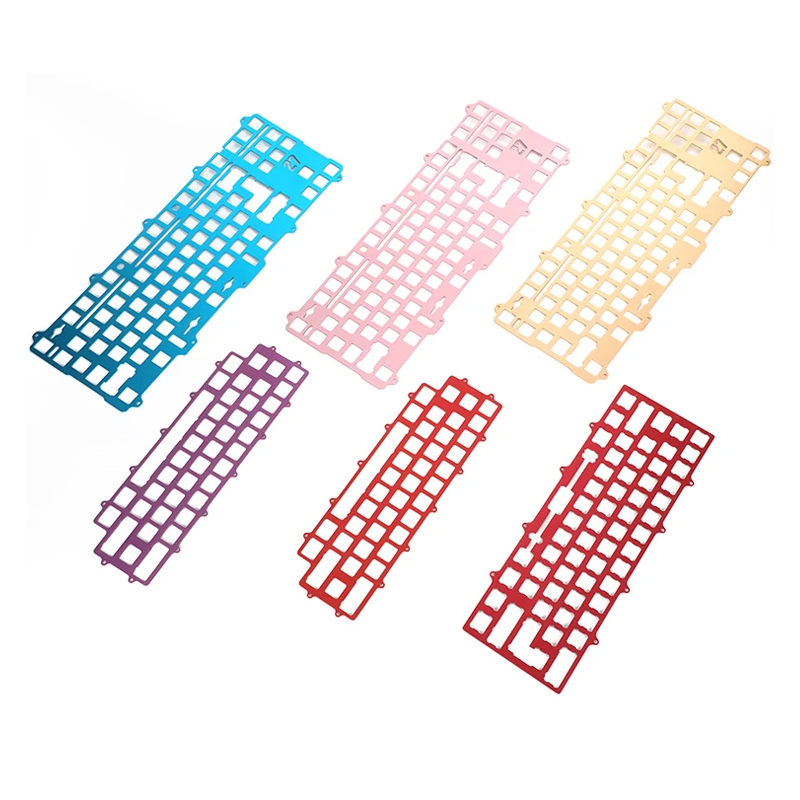

CNC machining allows for intricate designs and a high level of precision. This results in a sleek and professional appearance. The anodized finish available in various colors further enhances the visual appeal.

Customizability

Enthusiasts can customize every aspect of their CNC aluminum keyboard. This includes the layout, keycaps, switches, and case design. This level of personalization is often not possible with mass-produced keyboards.

Typing Experience

The weight and solidity of an aluminum case provide a stable and satisfying typing experience. The keyboard feels more substantial and less prone to flexing or shifting during use.

Thermal Management

Aluminum has excellent thermal conductivity. This helps in dissipating heat generated by prolonged typing or gaming sessions. It keeps the keyboard cool to the touch.

CNC Aluminum Keyboards in the Market

Several brands and custom keyboard makers offer CNC aluminum keyboards. Some of the most popular include:

Keychron

Known for their sleek designs and reliable performance, Keychron offers several models with CNC aluminum cases. Their keyboards are favored by both gamers and professionals for their build quality and aesthetics.

Massdrop CTRL

This keyboard is a favorite among enthusiasts for its hot-swappable switches and solid aluminum frame. The Massdrop CTRL offers a great balance between customizability and ease of use.

RAMA Works

A high-end custom keyboard manufacturer, RAMA Works produces limited-run CNC aluminum keyboards with unique designs and premium materials. Their keyboards are highly sought after by collectors.

KBDFans

Offering a wide range of custom mechanical keyboard kits, KBDFans provides options for CNC aluminum cases. They cater to different preferences and budgets.

Custom-Built CNC Aluminum Keyboards

For those looking to create a truly unique keyboard, custom-building a CNC aluminum keyboard is an exciting option. Here are some steps to guide you through the process:

Choosing the Layout

Decide on the layout you prefer, such as 60%, TKL (Tenkeyless), or full-size. This will determine the overall size and design of your keyboard.

Selecting the Case

Source a CNC aluminum case that fits your chosen layout. Many keyboard enthusiasts opt for cases from reputable manufacturers or custom makers.

Picking the Plate

The plate is an important component that holds the switches in place. Aluminum plates are common, but you can also choose from brass, steel, or other materials based on your preference.

Switches and Keycaps

Select switches that match your typing style, whether you prefer linear, tactile, or clicky switches. Keycaps come in various profiles and materials, allowing for further customization.

PCB (Printed Circuit Board)

The PCB is the heart of your keyboard. Choose a PCB that supports your layout and desired features, such as RGB lighting or hot-swappable sockets.

Assembly and Soldering

Assemble the components. If necessary, solder the switches to the PCB. This step requires precision and patience to ensure everything is correctly aligned and functioning.

Firmware and Programming

Load the firmware onto your PCB and customize the key mapping using software like QMK or VIA. This allows you to tailor the keyboard's functionality to your needs.

Conclusion

CNC aluminum keyboards represent the pinnacle of custom mechanical keyboards. They offer unparalleled durability, aesthetics, and customization options. Whether you choose a pre-built model or embark on a custom-building journey, a CNC aluminum keyboard enhances your typing experience. Tuofa supplier in china with CNC machining's precision and quality, these keyboards are tools for productivity and pieces of art that reflect the user's personality. As the mechanical keyboard community grows, CNC aluminum keyboards will remain a favorite among enthusiasts seeking the best in form and function. Get A Quote,Custom CNC Parts,Tuofa.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Understanding CNC Drawings and Related Concepts

Understanding CNC Drawings and Related Concepts