12 Ways to Cut Stainless Steel | Metal Cutting Guide

Apr 09,2024

Apr 09,2024

Stainless steel is renowned for its extraordinary corrosion resistance and durability and is widely used material in the industrial world. However, due to its hardness and specific properties it is difficult to cut through stainless steel. There are various ways available to cut through stainless steel. When it comes to cut stainless steel, you must have sufficient background knowledge about the cutting tools and ways to cut it. Because, a wrong decision can cause damage to the material as well as make the job difficult. It also causes loss of money too.

In this article of metal cutting guide, we will provide necessary information about 12 different effective methods to cut stainless steel accurately, ensuring clean and neat cuts and maintaining the reliability of material.

Is Stainless Steel Hard to Cut?

The presence of chromium and nickel in stainless steel make it strong, durable and corrosion resistance. These properties make stainless steel a challenging material to cut. Traditional cutting methods might not be able to cut the material effective. And, the use of improper tools can produce undesired results. However, it is possible to cut stainless steel efficiently and effectively using the right techniques and tools.

How to Cut Stainless Steel

Step 1 Preparing the workspace

Regardless of the method you are going to use in order to cut through stainless steel, you must have to prepare/create a workspace. Usually, a rigid and robust workbench is used for this purpose. This is because it is strong enough to achieve stable cutting. It is recommended that the work is done outside if you are using saw, grinder, or plasma cutter. However, If you are working with tools that are highly flammable, then ensure that the combustible materials in workspace are removed.

Step 2 Measuring for the cut

In order to cut accurately, the required area of the material is measured using tape measure. A marker can then be used to highlight the points and spaces. Ruler or square is used to cut a straight line on stainless steel because these can give a perfectly straight line.

Step 3 Cutting the Steel

The last step, after workspace preparing and marking of the material to cut out, comes is the selection of specific tool to perform the cutting operation. The selection of tool is basically done on the basis of thickness of stainless steel. Usually, tin snips are used to cut the stainless steel of thin thickness, whereas thick sheets of stainless steel required power shears, circular saws, or plasma cutters.

Stainless Steel cutting Tools

Stainless steel is famous for well renowned applications. These application ranges from cars to jewelry. Transforming it into a desired shape required a specific type of tool. Usually, the selection of tool depends upon the thickness of stainless steel and project you are working for. Regularly, the following types of tools are used:

- Tin snips (best to use for thin pieces of sheets)

- Power sheers (best to cut the stainless steel of thicker sheets)

- Circular saw implied for making custom patterns on stainless steel)

- Angle grinder (suitable for both thicker and thinner pieces of stainless steel sheet or tube)

- Plasma cutter (best for cutting suitable for extremely thick stainless steel which are impossible to cut with other tools)

- Dremal hand-held tool used for cutting high carbon steel and aluminum)

- Chop saw ( best for cutting thin sheets quickly and accurately)

- Jig Saw (suitable for longer cuts at high temperature without any damage)

- Band Saw (Similar to jigsaw except they have slow rate of cutting)

12 Ways to Cut Stainless Steel

There are many ways to cut stainless steel. In this article we are going to discuss 12 effective methods to cut stainless accurately. These are given as follow:

With an Angle Grinder

An angle grinder equipped with a cutting wheel is a hand help portable cutting tool. They are also famous for abrasive cutting. Due to their high cutting ability they are also employed to cut stainless steel. Angle grinder can make straight and curved cuts with ease. It is an affordable and used for cutting both thin and thick stainless steel. Always allow the tool to achieve required RPM before beginning the cutting process.

Sawing Stainless Steel

Different types of saws can be used to cut stainless steel. These include band saw, hack saw, circular saw, jigsaw, and chop saw. Beware of the cutting blade for cutting stainless steel. It is highly recommended that a cutting blade with the most teeth per inch would be used. Usually a carbide-tipped blade is ideal for cutting stainless steel sheets and plates. This method provides clean and straight cuts, making it suitable for various projects.

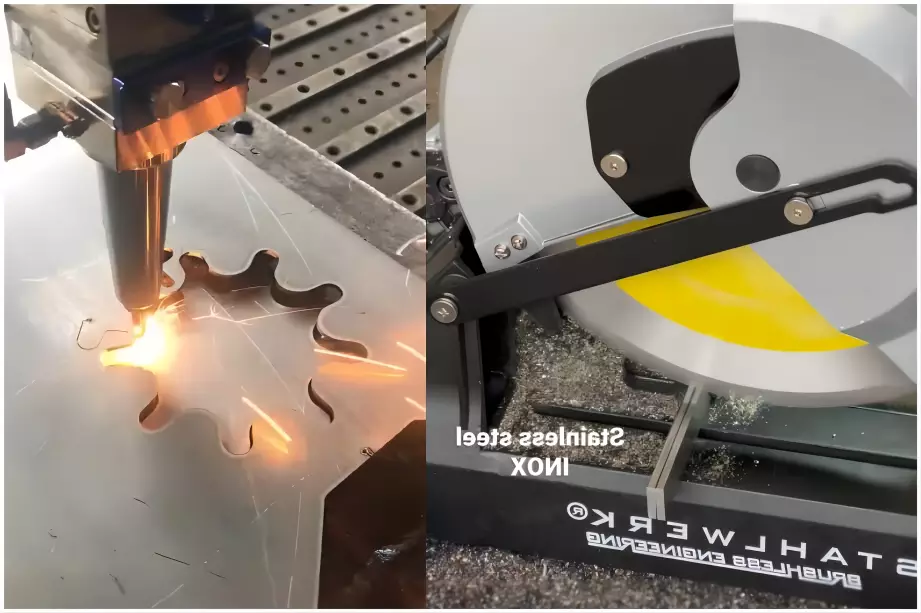

Laser Cutting

Laser cutting offers precision and is well-suited for intricate designs and thin to medium thicknesses of stainless steel. When using laser cutting on stainless steel, proper setting must be used. Material thickness, laser cutter type, and the required finish play a vital role in determining the best setting. It has been found that best results can be achieved using low power setting and slow speed. The working principle of laser cutting includes a high-energy laser beam to melt and vaporize the material along the cutting path.

Waterjet Cutting

In waterjet cutting process a high-pressure stream of water mixed with abrasive particles is employed to cut through stainless steel and other materials like aluminum, glass, and sometimes stones too. Waterjet cutting is best choice for materials of varying thicknesses and shapes. Usually this type of technique is used in automobile industries. This is due to their ease in creating complex design with precision and accuracy. Water jet cutting gives very smooth and neat cuts of stainless steel. These cut product of stainless steel do not require any type of finishing operation.

Shearing

Shearing cutting process is suitable for cutting thinner sheet thickness of stainless steel. This process also provides clean edges. Mostly, shearing cutti g process is employed in industrial settings for straight cuts.

Plasma Cutter

In Plasma cutting method, a high-temperature jet of ionized gas is used to cut through metals. It is best suited for thick sheets of metal rather than thinner sheets. It is also very easy and convenient to cut stainless steel with this method. It provides faster cutting speeds. The great advantage of using this technique is that it does not conduct electricity, which further enhance safety. Plasma cutting also produce less amount of burrs and can be used from simple to complex fabrication application.

Electrical Discharge Machining (EDM)

In this process an electric current is used to cut the metals. This electric current erode stainless steel, making it ideal for complex shapes and hardened materials. EDM gives a precise cut. It also does not create any heat affected zones. This is also a quicker process of cutting.

Tin Snips

When it comes to cutting thin sheets of stainless steel, Tin snips are best option. The working principle of tin snips is similar to that of scissors. Tin snips must be applied slowly to cut the metals. This will ensure safety and prevent cutting yourself.

Dremel

It is a handy tool and due to the design of the reinforced resin cutting wheel, it can cut stainless steel and aluminum. Usually dremel fitted with an abrasive cutting wheel is best suitable to cut stainless steel.

Oxy-Acetylene Torch

This type of cutting technique is mostly used by welders. In oxy-acetylne torch cutting process, a hot flame is used to cut the metals. While cutting stainless steel with this method, extra care must be taken in order to avoid any damage. Following steps are recommended while cutting stainless steel:

- Oxy-Acetylene torch must be at low setting and the flame is adjusted at about 1/2 inch long.

- The torch must be at an angle of 45-degrees

- The torch must be moved slowly along the line you want to cut.

- Finally, turn off the Oxy-Acetylene torch.

- At last allow the metal to cool down.

CNC Router

CNC router is very well known machine in the world for its numerous applications. It can be employed from cutting and engraving wood to milling aluminum and stainless steel. When cutting stainless steel using CNC router, following points must be followed

- It is used for cutting thin sheet metals

- CNC router took more time and take multiple passes to cut through the material

- A lot of amount of heat is generated in this process. So a cooling environment must be built

- A ventilation duct must be place, in order to remove the dust produced during this cutting process.

Drill

The drills are used to make holes in the metal sheets. When it comes to drill stainless steel, high speed steel drill bits are employed. Usually a blade with diamond or carbon teeth is used. It is highly recommend that drilling process must be done slowly, in order to ensure precision and accuracy.

Summary Chart of 12 Ways for Cutting Stainless Steel

This table provides a concise overview of each method along with important considerations or key points specific to each technique for cutting stainless steel.

| Method | Description | Key Points |

|---|---|---|

| Angle Grinder | Uses a cutting wheel, suitable for both straight and curved cuts. | High cutting ability, affordable, good for thick metal. |

| Sawing | Uses different types of saws like band saw, hack saw, etc. | Carbide-tipped blade recommended for clean cuts. |

| Laser Cutting | Employs a laser to melt and vaporize the material. | Precise, ideal for intricate designs. |

| Waterjet Cutting | Uses a high-pressure stream of water with abrasive particles. | Smooth cuts, no finishing required, versatile. |

| Shearing | Suitable for thinner sheets, typically used for straight cuts. | Provides clean edges. |

| Plasma Cutter | Utilizes a high-temperature jet of ionized gas. | Fast, convenient for thick metal, minimal burrs. |

| Electrical Discharge Machining (EDM) | Uses an electric current to erode the metal. | Precise, quick, no heat affected zones. |

| Tin Snips | Similar to scissors, ideal for cutting thin sheets. | Safe and slow application recommended. |

| Dremel | Handy tool fitted with an abrasive cutting wheel. | Effective for stainless steel and aluminum. |

| Oxy-Acetylene Torch | Uses a hot flame for cutting, requires careful handling. | Low setting, slow movement recommended. |

| CNC Router | Machine used for multiple materials including stainless steel. | Generates heat, requires cooling and ventilation. |

| Drill | Used to create holes, employs high-speed steel drill bits. | Slow drilling recommended for precision. |

Best Way to Cut Stainless Steel Sheet Metal

The selection of cutting method to cut stainless steel depends upon specific needs. Every method comes with advantages along with certain disadvantages. The factors like time, finish required and thickness of the material must be kept in mind while opting for process.

When you have to quickly cut the thick stainless steel, an oxy-acetylene torch is the best option. If cleaner cuts are your need then laser cutter or waterjet must be your selection. For a precise cut of stainless steel an EDM machine is recommended. And if you’re looking for a versatile option that can handle a variety of materials, a CNC router is a good option.

Stainless Steel Sheet Metal Cut to Size

Companies like Tuofa cnc machining specializing in metal fabrication can provide stainless steel sheet metal cut to the required size and specifications. We offer convenience and efficiency for various projects to cut to stainless steel.

How to Cut 1/4 Stainless Steel Plate

In order to cut ¼ inch thick stainless steel plates, a plasma cutter or a waterjet cutter is highly recommended. Precise and clean cuts can be ensured using these methods.

Cutting 304 Stainless Steel

There are various methods to cut 304 stainless steel as mentioned earlier. These include laser cutting, waterjet cutting, hacksaw or plasma cutting. Each method has its specific advantages and ensures clean and accurate cuts for this commonly used stainless steel grade.

How to Cut Stainless Steel without Discoloration

When stainless steel is cut, there may be chance of its discoloration. So in order to avoid discoloration of stainless steel during cutting, following tips must be followed.

1.A sharp blade must be used

2.The cutting must be done slowly and steadily

3.A cooling agent must be employed.

Best Way to Cut Stainless Steel Pipe

Are you looking for best method to cut stainless steel pipe? Or find it intimidated and complicated cutting stainless steel pipe? Then carefully read the following lines.

An angle grinder with a grinding cutting wheel and metal cutoff wheel designed for stainless steel is commonly used. It provides efficient and precise cuts on pipe sections.

Why Choose Tuofa to Cut Stainless Steel

Tuofa is one of the leading experts in cutting stainless steel. Tuofa utilizes the state-of-the-art tools and techniques to ensure precise cuts and top-notch results for all your metal cutting needs. With experienced professionals and a commitment to quality, Tuofa Company is your go-to partner for stainless steel cutting techniques and projects.

Conclusion

The Cutting stainless steel requires expertise and the right tools to achieve clean and accurate results. Each and every method that has been mentioned in this metal cutting guide has its various advantages, depending on the project's requirements and needs. For best results, it is recommended that you must consider seeking professional metal fabrication services for your stainless steel cutting techniques and needs. Appropriate cutting techniques can give exceptional properties and several advantages of stainless steel for various applications in construction, manufacturing, and beyond.

But still if you are confused and looking for best services to cut your stainless steel sheets, then Tuofa can best help you in this regard. Just leave us a message and we will help you with 100% reliability. Our staff has great experience in cutting stainless steel with precision and accuracy. Parts quotation contact info@tuofa-cncmachining.com

FAQs about Cut Stainless Steel

What is the easiest way to cut stainless steel?

An angle grinder is the easiest way to cut stainless steel. It consists of a cutting wheel designed for stainless steel. Angle grinder helps in cutting straight and curved cuts with ease, making it suitable for various cutting applications.

Where to buy stainless steel tables?

Stainless steel tables can be easily be found and purchased from hardware stores, home improvement centers, or online retailers which are specialized in metal furniture and equipment. Alternatively, you can consider custom fabrication for tailored solutions.

How to cut a stainless steel countertop?

Always an angle grinder with a cutting wheel or a circular saw with a carbide-tipped blade is used for cutting stainless steel countertop. Proper safety must be ensured. Use the angle grinder steadily to get smooth and for clean results.

What are stainless steel plate cutting techniques?

There is a various techniques to cut Stainless steel plates. These include laser cutting, waterjet cutting, plasma cutting, and abrasive waterjet cutting. Each method offers precise results for various stainless steel plate thicknesses.

What are some stainless steel cutting tips and tricks?

The following tips and tricks must be followed while cutting stainless steel:

- Always use appropriate cutting tool and protective gear.

- Keep the material cool during cutting to avoid discoloration.

- Work with experienced professionals or reputable fabrication companies like Tuofa for optimal results.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Bolt Vs Screw: What is the Difference Between?

Bolt Vs Screw: What is the Difference Between?