Copper Vs Aluminum Heat Sinks Which is Better

Jul 17,2023

Jul 17,2023

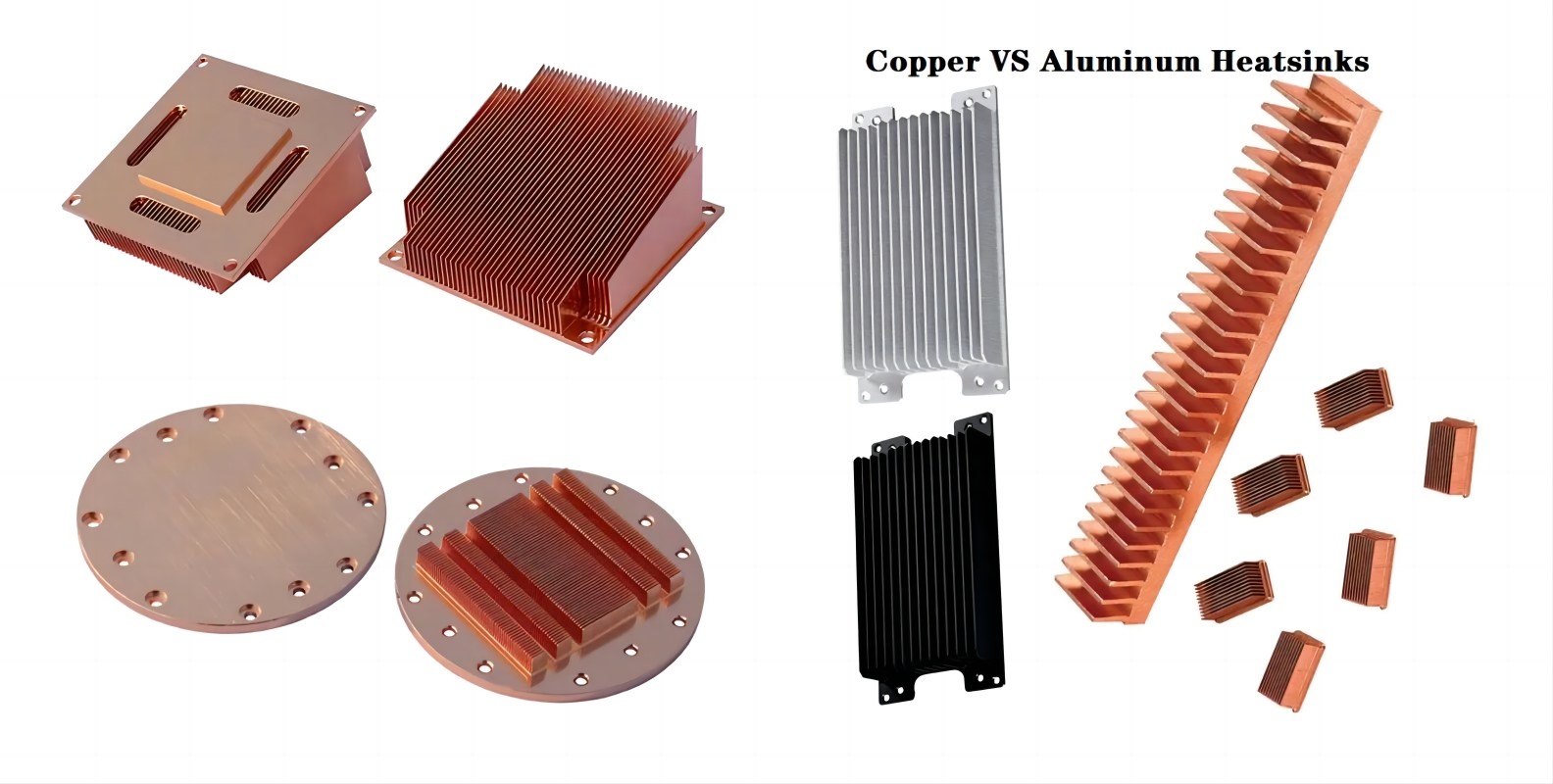

Heat sinks are essential elements of those systems which produce heat and remain at good level of temperature to prevent high temperature degradation. Copper property to control thermal energy at micro level of electronic circuit makes it emerging heat sink option for high tech computation industry. Copper vs Aluminum Heat sink material have aspects in Heat transfer, Thermal inertia, Thermal conductivity and Cost. Knowledge about these effects should be on table to judge the right material and thermal profile.

Heat Sink Material

This material removes heat from thermal side and make it available for atmosphere by free electron movement towards sink side. Major and important properties for these type of materials are efficiency of heat transfer, low weight, stability, ease in extrusion / machining and cost. Keeping in view of these properties optimum heat sink materials are Aluminum and Copper. Because metallurgy of these materials is feasible and have application in industry. But main question is to pick right and cheap heat sink material with good heat transfer functions / heat exchanger properties. For more information please see these YouTube videos.

Common Heat Sink Type

Heat Sink materials have different categories due to ease of manufacturing, extrusion, design type and application in equipments. Content of Copper vs Aluminum heat sink has also relation with types of heat sinks. Different types of heat sink materials are:

Heat Sink Profiles of Aluminum

Aluminum material has good extrusion properties with protrusion of thin fins and maximum surface area for heat transfer functions. These profiles are result of extrusion process. It is cheap, efficient, common available and good method of heat transfer. Figure.No.1 shows heat sink profiles of aluminum. Figure.No.1 Heat Sink Profile of Aluminum.

Figure.No.1 Heat Sink Profile of Aluminum

Round Aluminum Heat Sink

These profiles are circular with thin fins in radial direction and have protrusion along axial direction. They can radiate and convect heat to atmosphere by surface area. It is common way to control temperature of electronic devices. Figure.No.2 shows Round Aluminum Heat Sink Profile. Figure.No.2 Heat Sink Profile of Aluminum.

Figure.No.2 Heat Sink Profile of Aluminum

Full Copper CPU Cooler

It is more efficient and advance method to withdraw heat from high tech computer CPU to atmosphere. Conventional computer CPU may use aluminum heat sink but high tech computer CPU requires to export more joule energy per second. Therefore copper is best material for this activity because it can export more than forty percent heat joule per second than aluminum.

Electrical Copper Tube

Copper tubes transfer fluid from one high thermal energy to low temperature heat sink side in radiation and convection mode. It can take fluid and covects its heat on outer circumference of pipe with circulation mode. Heat transfer to atmosphere takes place by physical excitation / convection of air molecules and radiation.

What Metal Heats up the Fastest

If one make comparison for Copper vs Aluminum heat sink material and see Table.No.1, then it is clear that copper needs only thirty to forty percent of heat energy for heats up.

|

Copper |

Aluminum |

|

|

Heat Capacity. |

0.385 KJ/Kg.K |

0.90 KJ/Kg.K |

This fact is due to high thermal conductivity of copper and available high numbers of valence electrons. It makes temperature distribution of heat sink much easier for microelectronics devices. Because microelectronics need small amount of heat distribution instantly and copper can provide this provision to it.

Which Metal is the Best Conductor of Heat

Copper can conduct more heat energy (per second for one unit length and Kelvin temperature) due to large number of valence electrons and high electrons drift velocity. Table.No.2 also shows the same fact.

|

Copper |

Aluminum |

|

|

Thermal Conductivity |

385 W/m.K |

205 Wm.K |

Thus copper can provide more number of valence electrons at the terminal of negative end. It can conduct, covects and radiate heat way in any available direction to make component cool and efficient to working temperature range.

Best Heatsink Material

Best heat sink material depends upon following factors:

1. Have ease of manufacturing

2. Easy thin fin machining or extrusion

3. Conducts more heat in less time

4. Easy heats up

5. Thermal stability at high temperature

6. Ductile at working temperature

7. Cheap

If Copper vs Aluminum sink material have comparison with these 7 steps then it comes to point that not one material have all these properties. Therefore only option is to make priority of properties in one material for particular application.

Which is a Better Heatsink Copper or Aluminum

If the application involves microelectronics which requires less heat manipulation and can involve high cost, then copper is better heat sink than aluminum. But if product requires average amount of heat to dissipate from heat exchanger and does not afford high price for machining and material (copper heat sink price is more than aluminum) then aluminum is better heat sink material than copper.

Thermal Conductivity

Thermal conductivity defines efficiency and heat transfer functions of heat sink material at best level of temperature. Thus one can say that high thermal conductivity of copper makes it suitable for heat transfer in microelectronics without overheating of component even at low temperature. Table.No.2 shows the thermal conductivities of Copper and Aluminum.

Heat Sink Oxidize

Both heat sink materials get oxidation at high temperature but in case of copper it reaches to black oxidize at temperature of around two hundred fifty centigrade. But aluminum may oxidizes at temperature of four hundred degree centigrade which is not possible for heat sink material to develop after heat transfer. Figure.No.3 shows black oxidation of copper and aluminum. Chemical attack may also cause oxidation of both materials.

Figure.No.3 Copper Black Oxidation.

Weight and Cost

Weight: Copper is around three times denser and have weight per unit cube than aluminum which makes it less compatible for weight sensitive equipments. Table.No.3 shows density of Copper and Aluminum.

|

Copper |

Aluminum |

|

|

Density |

8.96 g/cc |

2.7 g/cc |

Table.No.3 Densities of Copper and Aluminum.

Cost: Due to high temperature metallurgy, less ore abundance and extraction of copper its cost is about three times high than aluminum, so copper heat sink is expensive than aluminum.

Machinability

Aluminum heat sink is good material for forming in fins dies and extrusion for final heat transfer shape with large surface area. This is common procedure for aluminum heat transfer heat sinks because of ease and versatile in nature. Sometimes CNC machining is need due to complex fins shape of aluminum profiles, thus machining is essential for these kinds of job. Copper is not good for extrusion of fins shape profiles because of high thermal energy use informing and shaping therefore it undergoes to machining.

Why Choose Tuofa Custom Heatsink

If application requires custom heat sink with parameters then only can expert tells to choose over Copper vs Aluminum heat sink materials. Customer can choose copper due to high thermal conductivity and aluminum due to its low cost, but Tuofa can do in depth analysis for metallurgy, Extrusion and CNC machining. Tuofa has ISO 9001 certification with experience in Heat Transfer functions and CNC machining of eat sink material. For example one can think of using liquid metal aluminum heat sink concept but Tuofa can tell about reactive reaction between liquid metal and aluminum heat sink. For more information please visit toufa-cncmachining.com.

FAQs about Metal Heatsink

Is Copper or Aluminum a better Conductor?

Copper is better conductor of thermal energy than aluminum but it is expensive and have limitation for fin profile extrusion and black oxidation. Copper can lose thermal conductivity if thermal conditions disturb the chemistry, anodizing reactions, valence electrons and corrosion properties.

Is Aluminum or Copper better for Heat Pipe?

Copper is better for heat pipe because it can conduct thermal energy to circumference of material, which further transfer it to atmosphere by radiate heat way and convection. But copper extrusion or drawing for pipe manufacturing has metallurgical limitation for extrusion.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Types of Rivets: Quality Rivet Selection Guide

Types of Rivets: Quality Rivet Selection Guide