Distinction Between A2 and A4 Stainless Steel: A Comprehensive Guide

Jul 15,2024

Jul 15,2024

The distinction between A2 and A4, or 304 and 316 stainless steels, is made according to their chemical composition and corrosion properties. A2 is used for general corrosion applications but A4 is used for specific corrosion applications. A detailed discussion of their properties and composition is discussed in this article. After reading this article you can appropriately do material selection between A2 and A4 for your application.

AISI 300 Series: A Family of Austenitic Stainless Steels

The 300 series of stainless-steel metal properties are due to the presence of austenitic stabilizing elements like nickel and chromium making them Austenitic stainless steel. 304 stainless steel and 316 stainless belong to the 300 series having metal properties like they have FCC crystal structure and are nonmagnetic. The corrosion properties of austenitic stainless steel are due to the presence of chromium, which when combined with oxygen forms a passive layer of chromium oxide.

This passive film protects the internal metal from corrosion. A2 and A4 contain 16-20%and 16-18 % of chromium. The presence of nickel and nitrogen in austenitic stainless steel provides an austenitic stabilizing effect to the 300 stainless series. Ni eq formula is used to quantify the nickel austenitic stabilizing effect. The stable austenitic structure indicates the ductility and corrosion properties of austenitic stainless steel.

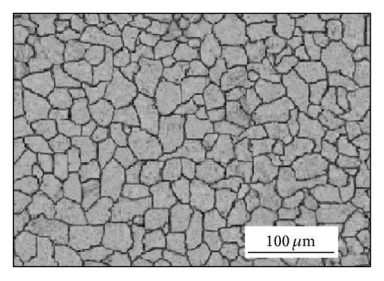

Austenitic stainless-steel microstructure.

A4 and A2 Stainless Steel of Equivalent Material

A4 and A2 Stainless Steel both belong to the 300 austenitic stainless-steel series but have different chromium, nickel, and molybdenum content. They are designated with different names in different naming standards.

Material equivalent to A2 304 stainless steel

- EN 1.4301

- UNS S30400

- JIS SUS304

- DIN X5CrNi18-10

A4 316 stainless steel equivalent material

- EN 1.4401 / 1.4404

- UNS S31600 / S31603.

- JIS SUS316

- DIN X5CrNiMo17-12-2 / X2CrNiMo17-12-2:

A2 Stainless Steel

A2 stainless steel, also designated as JIS SUS304 has a wide range of applications due to its good corrosion resistance, durability, and ease of manufacturing. From kitchen equipment to architecture structures, and automotive components A2 stainless steel is used everywhere. A2 is used for the general purpose of corrosion application.

A2 304 stainless steel CNC machined components manufactured in Toufa

A4 Stainless Steel

As compared to A2, A4 stainless steel are commonly known as JIS SUS316 has excellent corrosion resistance. Because it contains a higher amount of chromium and also has molybdenum protecting it from crevice and pitting corrosion. A4 stainless steel metal properties match best for marine applications because it provides excellent corrosion in chlorine environments. A4 316 stainless steel is also used in pharmaceutical industries.

A4 316 stainless steel component CNC machined by Tuofa.

The A2 304 stainless steel and A4 316 stainless steel technical differences are explained in the YouTube video below.

https://www.youtube.com/watch?v=ce1U4P8HHxc&pp=ygUYYTIgdnMgYTQgc3RhaW5sZXNzIHN0ZWVs

Is A4 stainless steel the same as A2?

NO! Both are different in composition and properties, UNS S30400 is designated to A2 stainless steel, and UNS S31600 is designated to A4 stainless steel. but both belong to the 300 series of austenitic stainless steel.

What Are the Common Forms of A4 and A2 Stainless Steel Material?

Common types of A2 and A4 include sheets, plates, bars, rods, tubes, pipes, wire, fasteners, fittings, and flanges.

A4 316 stainless steel components CNC machined by Tuofa.

Advantages and Disadvantages A4 and A2

The advantages and disadvantages of A2 and A4 stainless steel are discussed below.

Advantages and Disadvantages A4 Stainless

The advantages of A4 stainless steel are A4 has excellent corrosion resistance, high strength, and toughness making it durable, has hygienic properties, and aesthetic appeal, and is nonmagnetic. While disadvantages of A4 stainless include harder workability, not as easily available as A2, costly compared to A4.

Advantages and Disadvantages A2 Stainless

Advantages of A2 Stainless steel include ease of workability, cost-effectiveness, versatility, and good corrosion resistance. While the disadvantage of A2 304 stainless steel is limited corrosion resistance to chlorine environment and temperature sensitivity.

Applications and Parts

A2 is used to make parts of general corrosion protection applications like kitchen equipment, the Automotive industry, Architecture applications, consumer goods, and industrial equipment. While A4 stainless steel metal property of excellent corrosion resistance makes it used in making parts of applications like the Marine industry, pharmaceutical industry, chemical processing, and medical devices.

A4 316 stainless steel is used in marine applications.

Corrosion Resistance: Battling the Elements

A4 316 stainless steel has a high element of chromium and has the presence of molybdenum compared to A2 that’s why it has more corrosion properties even in a chlorine environment it protects itself against cervices and pitting corrosion.

A4 vs A2 Stainless Steel: Chemical Composition

The chemical composition of A4 and A2 stainless steel comparison is given below in the table.

|

Element |

A4 Stainless Steel (316) |

A2 Stainless Steel (304) |

|

Carbon |

almost equal to 0.08% |

0.08 percent |

|

Silicon |

1.00% |

1.00 percent |

|

Manganese |

2.00% |

almost equal to 2.00 percent |

|

Phosphorus |

almost equal to 0.045% |

almost equal to 0.045 percent |

|

Sulfur |

almost equal to 0.030% |

almost equal to 0.030% |

|

Chromium |

almost equal to 16.0-18.0% |

18.0-20.0 percent |

|

Nickel |

almost equal to 10.0-14.0% |

8.0-10.5 percent |

|

Molybdenum |

almost equal to 2.0-3.0% |

0.75 percent |

|

Nitrogen |

0.10% |

0.10% |

A2 vs A4 stainless steel magnetism is experimented with in the YouTube video below.

www.youtube.com/watch?v=mbbXvvpoLCo&pp=ygUYYTIgdnMgYTQgc3RhaW5sZXNzIHN0ZWVs

Comparative Analysis of Key Elements: Chromium, Nickel, and Molybdenum

chromium content is higher in A2 compared to A4. A4 has a higher nickel content. Molybdenum is present in 2-3% in A4 but very less or almost absent in A2.

AISI A2 stainless steel vs A4: Corrosion Resistance

For the general purpose of corrosion protection A2 is best because is cost effective and provides enough corrosion protection. A4 is for special corrosion protection applications due to superior corrosion protection even in a chlorine environment.

A4 vs A2 Stainless: Physical Properties

The physical properties of A2 and A4 are compared and discussed below.

Density

A4 JIS SUS316 stainless steel has density of 8.0 g/cm³ slightly greater than A2 JIS SUS304 stainless steel having density of 7.9 g/cm³

Melting Point

A4 JIS SUS316 stainless steel has a melting point of 1370-1400°C while A2 JIS SUS304 stainless steel has a melting point of 1400-1450°C.

Magnetism

Both are nonmagnetic in nature and are austenitic.

Thermal Conductivity

A4 JIS SUS316 stainless steel has a thermal conductivity of 15 W/m·K while the thermal conductivity of A2 JIS SUS304 stainless is 16-17 W/m·K.

Coefficient of Thermal Expansion

A4 JIS SUS316 stainless steel has a CTE of 16.5 µm/m·K, whereas A2 JIS SUS304 stainless steel has a CET of 17-18 µm/m·K

Electrical Resistivity

A4's electrical resistivity is 0.74 µΩ·m while the electrical resistivity of A2 stainless steel is 0.72-0.78 µΩ·m.

A4 vs A2 Stainless Steel: Mechanical Properties

A4 and A2 Stainless Steel have different chemical compositions which leads to different mechanical properties which are discussed below.

Tensile strength

A2 stainless steel (UNS S30400) has a lower tensile strength of 250 to 350 MPa than A4 stainless steel (UNS S31600) having a tensile strength of 300 to 400 MPa.

Young’s modulus

A2 stainless steel designated as UNS S30400 and A4 stainless steel designated as UNS S31600 have the same Young's modulus of 190 to 210 GPa.

Compressive strength

Both A2 and A4 have excellent compression strength. A2 has a compression strength of 54-174 MPa while A4 has a compression strength of 180-204 MPa.

Shear strength

A2 stainless steel (UNS S30400) has a lower shear strength of 250 to 350 MPa than A4 stainless steel (UNS S31600) having a shear strength of 300 to 400 MPa.

Yield strength

A2 stainless steel (UNS S30400) has a lower yield strength of 205 MPa than A4 stainless steel (UNS S31600) having a yield strength of 240 MPa.

Shear modulus

A4 due to higher shear strength also has a higher shear modulus compared to A2.

Fracture toughness

A4 has more strength than A2 stainless steel which also leads to higher fracture toughness of A4 compared to A2.

Elongation

A2 has a slightly higher elongation of 50-60% while A4 has an elongation of 40-50%.

Impact strength

A2 stainless steel (UNS S30400) has a lower impact strength of 100 to 150 J/cm² than A4 stainless steel (UNS S31600) having an impact strength of 50 to 100 J/cm².

Resilience modulus

A2 stainless steel (UNS S30400) has a resilience modulus of 140 to 180 GPa and A4 stainless steel (UNS S31600) has a resilience modulus of 150 to 200 GPa.

Machinability

CNC machine stainless steel parts require special equipment and an experienced worker with great expertise. CNC machining of A2 is far easier than A4 because A2 is ductile compared to A4. Tuofa Stainless Steel Parts Supplier contains advanced CNC machining and experienced workers to produce CNC machined A2 and A4 stainless steel parts. You can get more information from their website given below.

https://www.tuofa-cncmachining.com/

Summarize Differences Between A2 and A4 Stainless Steel

The key difference between the A2 and A4 stainless steel comparison is given below in the table.

|

Feature |

A2 Stainless Steel (304) |

A4 Stainless Steel (316) |

|

Chromium (Cr) |

18.0-20.0% |

16.0-18.0% |

|

Nickel (Ni) |

8.0-10.5% |

10.0-14.0% |

|

Molybdenum (Mo) |

≤ 0.75% |

2.0-3.0% |

|

Corrosion Resistance |

Good general resistance |

Superior resistance, especially against chlorides and marine environments |

|

Applications |

Household, industrial applications, kitchen equipment, general construction |

Marine, chemical, and pharmaceutical industries |

|

Cost |

Generally, less expensive |

More expensive due to higher performance |

|

Mechanical Properties |

Similar, but slightly lower in aggressive environments |

Better in specific conditions like higher temperatures and aggressive environments |

Is A2 or A4 Stainless Steel Better

A2 and A4 both have their applications and properties making them unique from each other. A2 has good corrosion protection for general purposes while giving durability and ease of CNC machining. A4 is harder to machine but provides superior corrosion protection compared to A2.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Soft Tooling vs Hard Tooling: A Comprehensive Guide

Soft Tooling vs Hard Tooling: A Comprehensive Guide