8 Ways to Cut Carbon Fiber | Which do You Prefer

Aug 18,2023

Aug 18,2023

11234

11234

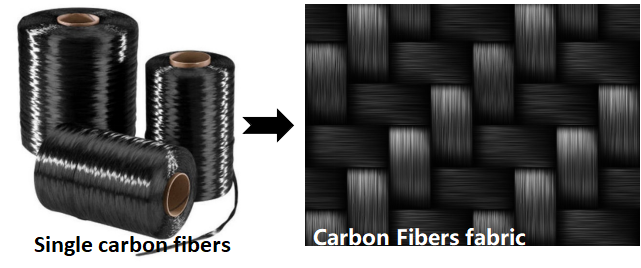

After Iron Age and Bronze Age, the modern time is the era of carbon fibers. They mainly composed of carbon atoms in regular repeating three-dimensional network. The fundamental property which makes them superior than conventional material is their “very high strength to weight ratio”. Carbon fibers finds their application in almost all areas of life now a days e.g., aerospace, automotive, manufacturing industries and even in households. From sailing ships to racing cars all recent developments are incomplete without the use of carbon fibers. As a latest engineering material, their cutting is a major challenge for manufacturers. This article will cover all aspects of carbon fiber cutting.

It took a second to think about safety, but a whole life to regret on an accident. The cutting of carbon fibers seems simple. It generates carbon fiber dust while cutting. This carbon fiber dust can cause irritation at the skin and result in breathing problem if inhaled. So, always use PPEs while cutting carbon fibers.

Is Carbon Fiber Easy to Cut?

Carbon fibers can be cut with ease if and only if proper tool and appropriate methodology is used. Carbon fibers cannot be cut or sectioned like other conventional material like iron, copper, aluminum or plastics. Very high strength, stiffness and high temperature resistance make then difficult to cut using conventional tools and techniques.

Normally carbon fibers used in the form of polymer matrix composite. This composite consists of highly strong carbon fibers and relatively weak polymer matrix. Soft and hard layers of this composite cause problem for conventional cutting tools and equipment.

Can you cut carbon fiber

You can cut carbon fiber using their specialized tools and techniques. They are used in almost all areas of life now a days. The manufacturing of components made up of carbon fiber and their composite include frequent cutting of various sizes and thicknesses. The manufacturers also use appropriate tools to cut these materials. Carbon fibers can be cut at home, in workshop and in industries on a larger scale using specific cutting tools.

Click on the link for further information;

Which carbon fiber products need to be cut

Complex structures and components made up of carbon fibers initially consist of following simple products:

- Carbon fiber pipe

- Carbon fiber sheet

- Carbon fiber tube

- Carbon Fiber Rod

Other simple products involve sandwich panels, non-woven fabrics, prepregs, tapes and sleeves and unidirectional fabric etc.

Among above mentioned products, carbon fibers sheets are widely used in several applications which includes aircraft components, bicycle bodies, car bodies, ships, car seats and hundreds of other important components.

Carbon Fiber Cutting Tools and Equipment

Fundamentally there are two types of tools to cut carbon fiber and their composites. They are “manual tool and power tools”. The use of specific type of tool depends upon type, thickness and shape of carbon fibers. Thin sheets, thick sandwich panels, solid rods, hollow pipes or complex shapes, all products require separate tooling for effective cutting. For example, a thin fabric of carbon fiber can be cut with an ordinary scissors. The selection of specific tool also depends upon the precision of cutting. Usually, ordinary scissors produce rough cutting edges.

Manual cutting tools involve scissors, shear cutter and simple razor blades. Powered cutting tools involve angle grinder and dremel tools. Angle grinder is usually mounted on any rotating motor to cut carbon fibers.

How to Cut Carbon Fiber: 10 Way

Carbon fibers can be cut in several ways using various tools and multiple equipment’s. The choice of any cutting technique depends upon following factors:

- Precision of cutting required

- Thickness of carbon fiber product

- Volume of cutting

- Size of the cutting product

- Shape of the product

Once you have decided the product, you have to cut and its application, selection of cutting technique become easy. Following are the techniques used worldwide to cut carbon fibers and their composites:

- Cutting of carbon fibers with shear cutters

- Hacksaw blade for carbon fiber

- Plasma cutting carbon fiber

- Laser cut carbon fiber

- Water jet cutting carbon fiber

- CNC carbon fiber cutting

- Cutting carbon fiber with dremel

- Cutting using Abrasive wheel

- Hot knife cutting

- Electric Jigsaw cutting

10 Way Cut Carbon Fiber Summary Chart

Before going into details of each cutting method of carbon fiber, here is a very brief summary of all above mentioned cutting techniques:

Table-1 Summery of cutting methods for carbon fibers

|

Sr. No. |

Cutting Technique |

Description |

|

1 |

Hacksaw blade for carbon fiber |

This technique is used for cutting hard and thick layers of carbon fiber composite. Only suitable for straight cuts and rough surfaces. |

|

2 |

Cutting of carbon fibers with shear cutters |

Various types of scissors are used to cut carbon fibers. This technique is not suitable for precise cutting. |

|

3 |

Plasma cutting carbon fiber |

High temperature arc of plasma is used to cut the carbon fiber composites. It is used at industrial scale. |

|

4 |

Laser cut carbon fiber |

High intensity laser is used to cut the carbon fibers. It also melting methodology to cut the material. |

|

5 |

Water jet cutting carbon fiber |

High velocity and water jet is used to cut carbon fiber composites. It is useful to cut intricate shapes at industrial scale. |

|

6 |

CNC carbon fiber cutting |

Complex and intricate shapes of carbon fiber composites are cut using computer aided model. Selection of tool is important to achieve required surface and cutting results. |

|

7 |

Cutting carbon fiber with dremel |

Small and less precious cuts on carbon fibers can be achieved using dremel tool. It is a small handy tool in which any cutting wheel is attached which is suitable for carbon fiber cutting. |

|

8 |

Cutting using Abrasive wheel |

A suitable cutting wheel e.g. diamond coated abrasive wheel mounted on a rotating motor is used to cut carbon fibers. |

|

9 |

Hot knife cutting |

This technique is useful for small scale and for rough cutting. In which a hot knife edge is used to cut carbon fibers. |

|

10 |

Ultrasonic cutting technique |

A suitable cutting tool mounted with a vibration source operating at ultrasonic frequency is used to precisely cut carbon fibers. |

Details of each cutting technique along with its mechanism and application is given below:

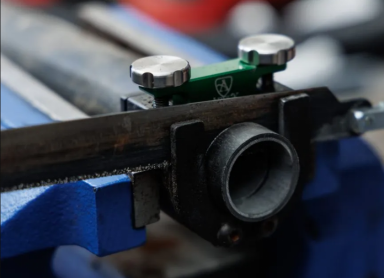

Hacksaw blade for carbon fiber

Carbon fiber can be sectioned and cut using hacksaw blades. Usually, fine tooth blades are used for this purpose. The product to be cut is gripped in a fixture and cutting is performed with linear direction with to and fro movement of hacksaw. In this technique of cutting, carbon fiber dust is generated which may cause damage to skin and effect breathing. This technique is not useful for precise cutting. It can only be used for straight and rough cutting. Complex shapes cannot be cut using this technique.

Plasma cutting carbon fiber

This cutting technique for carbon fiber composites, involve cutting of carbon fibers using high temperature plasma arc which blow away the molted metal. The plasma cutting technique consist of a huge setup which create high temperature plasma arc using a plasma gun. Carbon fiber composite of varying thicknesses can be cut using this technique. A very fine cutting surface is achieved by plasma arc cutting. Simple to complex shapes can be cut by plasma arc.

As cutting is performed by melting of fibers, the delamination of carbon fibers and polymer matrix is not possible without proper cooling while cutting. This special cutting is used at large industrial scale to mass production.

Laser cut carbon fiber

The fundamental cutting principle of laser cutting of carbon fibers is same as that of plasma cutting. In laser cutting, high energy laser melt the carbon fibers and blow away the molten material. Very fine intricate shapes of varying complexity can be cut using laser cutting. The cutting surface finish depends upon energy of laser generating source. A specific combination of laser energy, travel speed is used for a particular thickness of carbon fiber composites cutting.

The carbon fiber composite is placed in the cutting bed and high energy laser beam is directed in the work piece. Usually, CNC carbon fiber cutting methodology is employed while using laser cutting. Appropriate cooling of work piece is important to safe carbon fiber composite polymer matrix from delamination. Any type of custom cut carbon fibers can be made using this technique.

Water-jet cutting carbon fiber

Water jut cutting of carbon fiber cutting a very special technique which uses a high velocity water jet to cut the required surfaces of carbon fiber composites. The work piece is placed on the cutting bed and CNC program is used to cut intricate shapes. This technique doesn’t produce carbon fiber dust as it is trapped in water jet of water and collected later. This cutting technique is usually used in large industries for huge production.

CNC carbon fiber cutting

Computerized numeric control carbon fiber cutting is used for making complex and intricate shapes. Usually, for this purpose a separate fiber cutting machine is used as collection of carbon fibers dust is an important consideration in this type of cutting. The cutting of carbon fibers is usually carried out in carbon fiber machining services setups. Selection appropriate cutting tools is an important criteria for successful cutting operation. Linear, angular, round or irregular shapes can be cut using CNC cutting technique. The part is placed on the cutting bed and cutting is performed using an appropriate tool.

Cutting carbon fiber with dremel

Dermal is used when rough and small cutting is required. An appropriate rotating abrasive cutting wheel is mounted with dremel. In this technique the edges of the cutting become rough and delamination of carbon fibers and polymer matrix is possible. Usually, intricate and complex shapes cannot be cut using this rough technique. Straight cutting is only possible option using dremel cutting technique.

Utrasonic Cutting of carbon Fiber

This special cutting technique is a modification of conventional cutting technique of cutting carbon fibers. In this technique a sharp cutting tool (e.g. fine tooth hacksaw) is attached with a vibrator. The vibration machine vibrates at ultrasonic frequency to cur the sample surface. Very sharp and fine cutting is possible using this technique provided an appropriate cutting tool is used. Usually complex and intricate shapes cannot be cut using this technique. The high frequency allows the cutting tool to create very fine and clean cutting edges.

Hot knife cutting

Simple and rough cuttings of carbon fibers is also possible using hot knife edge. Usually a red hot knife is used to cut thin sheets of carbon fiber. The drawback of this technique is highly rough surface and nonlinear cutting. However, the heated surface of knife does not produce too much carbon fiber dust.

The answer of this question based on the type of product to be cut, size of carbon fiber composite and required accuracy and precision of design. If we consider accuracy of cutting, ease of cutting of complex shapes, ease of cutting, cutting speed and safety; water-jet cutting method is best method among all above discussed methods.

Best Way to Cut Carbon Fiber

The answer of this question based on the type of product to be cut, size of carbon fiber composite and required accuracy and precision of design. If we consider accuracy of cutting, ease of cutting of complex shapes, ease of cutting, cutting speed and safety; water-jet cutting method is best method among all above discussed methods.

How to cut carbon fiber handlebars

If you require to cut handlebar by yourself, first of all, mark the dimensions which are needed to be cut. After that, with the help of fine-tooth hacksaw blade, start cutting the handlebar. After cutting of the handle bar, rub the cutting edges with the help of fine sand paper. Don’t forget to wear PPEs before cutting.

Cutting carbon fibers are used to make carbon fiber composites which further used to manufacture engineering components, assemblies and sub assembles. Aircraft, drones, sports cars. Bicycles, ships are few common examples of use of carbon fiber cuttings.

There are two commonly used cutting methods which are used to cut Titanium metal. Sold rods or pipes can be successfully cut using abrasive wheel cutting. EDM wire cutting is also an important and useful method to cut carbon fiber.

Cutting of carbon fibers is relatively difficult and more complex as compared to conventional materials. The precise cutting techniques preserve its property if high strength to weight ratio is required. Using appropriate techniques, complex shapes can be fabricated which are not possible with ordinary materials. On the other hand, there are also some challenges in carbon fiber cuttings. The specialized cutting equipment is expensive. There are few health hazards in carbon fibers cutting. Without high expertise delamination of carbon fibers with matrix took place causing damage of component.

You must choose tuofa for the cutting of carbon fiber as it provides you precision cutting for your desired component without damage or reducing the properties of the fiber. Tuofa is well known for its highly automated equipment’s, expert engineers, and best customer services. For further information, contact on our website.

What is Cutting Carbon Fiber Used For

Cutting carbon fibers are used to make carbon fiber composites which further used to manufacture engineering components, assemblies and sub assembles. Aircraft, drones, sports cars. Bicycles, ships are few common examples of use of carbon fiber cuttings.

Tips for Successful Cutting of Carbon Fiber

There are two commonly used cutting methods which are used to cut Titanium metal. Sold rods or pipes can be successfully cut using abrasive wheel cutting. EDM wire cutting is also an important and useful method to cut titanium metal.

Pros and Cons of Carbon Fiber Cutting

Cutting of carbon fibers is relatively difficult and more complex as compared to conventional materials. The precise cutting techniques preserve its property if high strength to weight ratio is required. Using appropriate techniques, complex shapes can be fabricated which are not possible with ordinary materials. On the other hand, there are also some challenges in carbon fiber cuttings. The specialized cutting equipment is expensive. There are few health hazards in carbon fibers cutting. Without high expertise delamination of carbon fibers with matrix took place causing damage of component.

Why Choose Tuofa to Custom Carbon Fiber Cutting Service

You must choose tuofa for the cutting of carbon fiber as it provides you precision cutting for your desired component without damage or reducing the properties of the fiber. Tuofa is well known for its highly automated equipment’s, expert engineers, and best customer services. For further information, contact on our website.

FAQs about Cutting Carbon Fiber

How to cut carbon fiber at home

Carbon fibers can be cut at home using fine tooth hacksaw blade. First, fix the carbon fiber with some solid support and start cutting the marked area of carbon fiber composite. Finely, clean the edges with fine sand paper.

Can you cut carbon fiber with scissors

If the sheet is very thin and size is small, you can also cut carbon fiber fabric using an ordinary scissors at home. Thick sheets or hard components of carbon fiber can’t be cut using a scissors at home.

Blade for cutting carbon fiber

Fine tooth carbide blade or diamond coated blades can be effectively used to cut carbon fiber composites. However, cutting speed of diamond coated cutting blade is slower than simple carbide blades, but it gives you very fine and smooth cutting surface.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

German

German French

French Spanish

Spanish Russian

Russian Arabic

Arabic Norwegian

Norwegian Dutch

Dutch Finnish

Finnish Japanese

Japanese Chinese (Simplified)

Chinese (Simplified) Home

Home

How to Drill Metal: 15 Ways

How to Drill Metal: 15 Ways