316 vs 321 Stainless Steel: What's the Difference

May 04,2024

May 04,2024

316 vs 321 Stainless Steel both have different properties that’s why both have their own unique application. Studying 316 vs 321 stainless steel in detail to understand difference between them is very crucial to decide best grade between them that best full fill industry standards for specific application like automotive and marine applications. Other designations used for 321 stainless steel are UNS S32100 and ASTM A240 Type 321 while for 316 SS are UNS S31600 and ASTM A193 Grade B8M.In this article we will understand major difference between chemical composition, properties, and particular environment in which 316 vs 321 Stainless Steel can be used.

Advantages and disadvantages 316vs 321 Stainless Steel

|

Criteria |

316 Stainless Steel |

321 Stainless Steel |

|

Advantages |

● Excellent corrosion resistance ● Good weldability ● Moderate to high strength ● Widely used in marine applications. |

● Good, elevated temperature resistance. ● Excellent weldability ● Good creep resistance ● Common in elevated-temperature applications. |

|

Disadvantages |

● Post-weld annealing is required. ● Moderate elevated-temperature resistance |

● Higher in cost ● less formable ● Machining is difficult. |

Table show advantage and disadvantage of 316vs 321 Stainless Steel.

YouTube video showing difference between stainless steel including 316 and 321 grades.

https://www.youtube.com/watch?v=HFqKNQGBHvs&pp=ygUNMzE2IHZzIDMyMSBTUw%3D%3D

SS 321 vs SS 316L

SS 321 have titanium stabilization has major application at elevated temperature. Show good creep compared to 316 SS. 316 SS is austenitic stainless steel used mainly in application requires high chemical resistance like marine applications and chemical processors.

What is 321 steel equivalents to?

321 SS has equivalence to some other international grades listed below:

- X10CrNiTi18-9 which is written EU EN form.

- SUS321 which is written JIS Japanese style.

- Z6CNT18-10 which is written in AFNOR (France) form.

- WNr form of this grade is X6CrNiTi18-11 which is Germany DIN style.

- 0Cr18Ni10Ti is Chinese GB form.

- 2337 is SS Swedish form.

- X6CrNiTi18-10 is GOST Russian style.

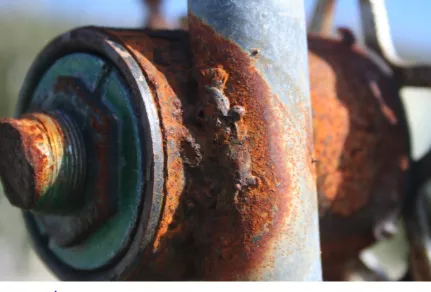

Does 321 stainless steel rust?

Although the presence of titanium stabilization in UNS S32100 make it good corrosion resistance but compared to UNS S31600 it has low corrosion resistance and get rusted when exposed to corrosive environment for prolong time. Also, main reason for rusting in UNS S32100 is improper fabrication.

Image showing 321 SS rusting.

Typical Uses in Industry

321 stainless steel fulfill industry standards for applications like aerospace, automotive and power generation etc. While 316 SS full fill industries standard for application like chemical processors, marine application, food processing and pharmaceuticals.

From Metal Garden Hoses to Pharmaceutical Equipment

UNS S31600 due to its corrosion resistance and degradation resistance even when exposed to outdoor environment for long period of time make it suitable to use in metal garden hoses. UNS S31600 hygiene and corrosion resistance ability fulfill industry standards for making pharmaceutical equipment.

Image showing SS 361 Metal Garden Hoses.

Working Pressure and ANSI Pressure Ratings

UNS S32100 is best for moderate to high pressure applications the selection of best class for this application depends upon pipe size, pipe thickness and temperature. Class 150 to 300 is typical range.

Use in High-Temperature Settings: Aerospace to Exhaust Systems

ASTM A240 Type 321 is the best candidate for elevated temperature applications. ASTM A240 Type 321 full fill all industrial standards for elevated temperature applications that’s why ASTM A240 Type 321 is the best candidate to fabricate exhaust system for aerospace.

Image showing 321 SS exhaust.

What is the Difference Between 316 ss and 321 ss?

316 SS is the austenitic stainless steel with high nickel and molybdenum content compared to 321 SS which make it excellent corrosion resistive even in chlorine environment that’s why is best suitable for marine applications. 321 SS in addition to nickel and molybdenum content it also has titanium stabilization making it suitable for elevated temperature application. 321 SS don’t allow chromium carbide precipitation during welding and hence prevent intergranular corrosion.

Chemical Composition

|

Element |

316 Stainless Steel (Weight %) |

321 Stainless Steel (Weight %) |

|

Carbon (C) |

≤ 0.08 |

≤ 0.08 |

|

Silicon (Si) |

≤ 1.00 |

≤ 1.00 |

|

Manganese (Mn) |

≤ 2.00 |

≤ 2.00 |

|

Phosphorus (P) |

≤ 0.045 |

≤ 0.045 |

|

Sulfur (S) |

≤ 0.030 |

≤ 0.030 |

|

Chromium (Cr) |

16.0 - 18.0 |

17.0 - 19.0 |

|

Nickel (Ni) |

10.0 - 14.0 |

9.0 - 12.0 |

|

Molybdenum (Mo) |

2.0 - 3.0 |

- |

|

Titanium (Ti) |

- |

5x(C+N)min, 0.70 max |

|

Nitrogen (N) |

- |

0.10 max |

Addition of Titanium: Preventing Carbide Precipitation

The chromium content in stainless steel form a chromium carbide precipitation and cause intergranular corrosion. The addition of titanium stabilization in 321 SS prevents formation of these carbide precipitation and hence prevent intergranular corrosion.

Comparison of AISI Standards for 321 vs. 316

AISI 321 also known as UNS S32100 has EN standard as X6CrNiTi18-10 and Japanese standard as SUS321. AISI 316 also known as UNS S31600 has EN standard as X5CrNiMo17-12-2 and Japanese standard as SUS316.

Corrosion Resistance

Although ASTM A240 Type 321 prevent intergranular corrosion, but it may get rusted when exposed to outdoor environment for prolonged time but compare to it UNS S31600 shows best corrosion resistance even in chlorine environment.

Mechanical Properties

|

Property |

316 Stainless Steel |

321 Stainless Steel |

|

Density (g/cm³) |

8.00 |

8.00 |

|

Melting Point (°C) |

1370–1400 |

1398–1420 |

|

Specific Heat (J/kg·K) |

500 |

500 |

|

Thermal Conductivity (W/m·K) |

16.2 |

16.3 |

|

Electrical Resistivity (Ω·m) |

7.98 x 10^-7 |

7.43 x 10^-7 |

|

Modulus of Elasticity (GPa) |

193 |

193 |

|

Poisson's Ratio |

0.3 |

0.3 |

|

Thermal Expansion (μm/m·K) |

16.5 |

16.6 |

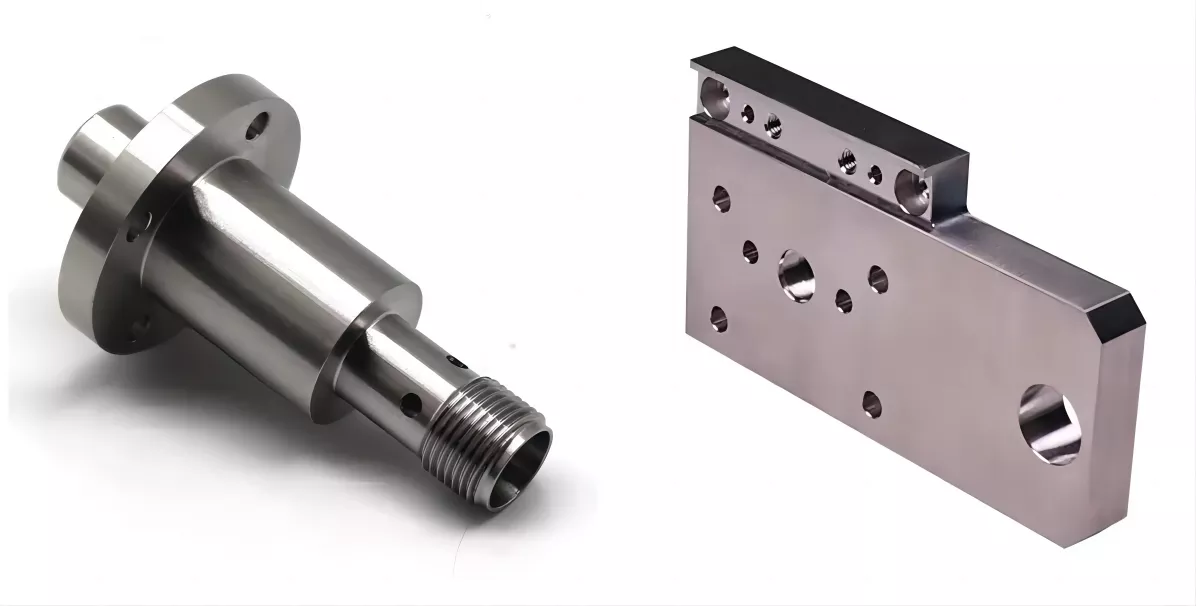

CNC machining capabilities

ASTM A240 Type 321 is harder compared to ASTM A193 Grade B8M so the CNC machining of 321 is challenging compared to 316 SS. 316 SS is ductile and formable that’s why the CNC machining of 316 SS is smooth and provide excellent surface finish.

Heat Treatable Stainless Steel

316 SS is austenitic in nature compared to it 321 SS is heat treatable stain less steel it is went through following treatments to enhance it mechanical properties and for stress relieving.

- Annealing (870to 900°C)

- Solution annealing (950 to 1050°C)

- Stress relieving (500 to 700°C)

- Aging (700 to 900°C)

Cost

321 SS is expensive compared to 316 SS.

Summary Chart of AISI 316 and 321

|

criteria |

316 Stainless Steel |

321 Stainless Steel |

|

Corrosion Resistance |

Excellent |

Good |

|

High Temperature Resistance |

Up to 870°C (1600°F) |

Up to 900°C (1650°F) |

|

Weldability |

Good, may need annealing |

Excellent, no annealing needed |

|

Strength |

Moderate to high |

Similar, better creep resistance |

|

Cost |

Moderate |

Slightly higher |

|

Applications |

Marine, chemical processing |

High-temperature environments |

|

Machinability |

Good |

Slightly more difficult |

|

Formability |

Good |

Slightly less |

|

Oxidation Resistance |

Up to 925°C (1700°F) |

Up to 870°C (1600°F) |

Which is Better 316 or 321 Stainless?

Both are better for specific applications because of their unique properties 321 SS is better for application that requires high temperature while 316 SS is better for corrosion resistive applications.

Conclusion

316 and 321 stainless steels represent versatile and reliable materials, each with its unique strengths. By carefully evaluating application requirements, including corrosion resistance needs, operating environments, fabrication considerations, and cost factors, you can make informed decisions, selecting the optimal stainless steel grade for their specific needs. Consulting with Tuofa materials experts can further guide the selection process, ensuring the chosen material aligns perfectly with the application demands.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

300 vs 400 Series Stainless Steel: Which Triumphs?

300 vs 400 Series Stainless Steel: Which Triumphs?