10 Methods for Removal Chrome Plating

Oct 07,2023

Oct 07,2023

You must know the chrome plating. It is almost impossible to not know if you have worked on making glossy and shiny any material. But it is important to know about the basic information of coating anything on any material. And sometimes it is about removing the coat from the material which is harder than coating any material. Therefore, this article will present basic facts and information about removal chrome plating from different materials. This will start by discovering different removal processes then lead to different materials and pros and cons of chrome plating and finish removal.

How to Remove Chrome Plating: 10 Methods

Chrome plating is carried out electroplating which is adding a layer over metal of different material by surface treatment. This provides corrosion resistant to metal and improves its service life and adds beautification in product. However, there are many reasons that sometimes this coating is not so productive, and advantages and one must remove this. This is because it may be damaging the material instead of protecting it or must be torn so that it does not look so attractive. Therefore, one must know about the removal processes of chrome coating or finish removal from material which is discussed below:

Remove Chrome Plating Applications

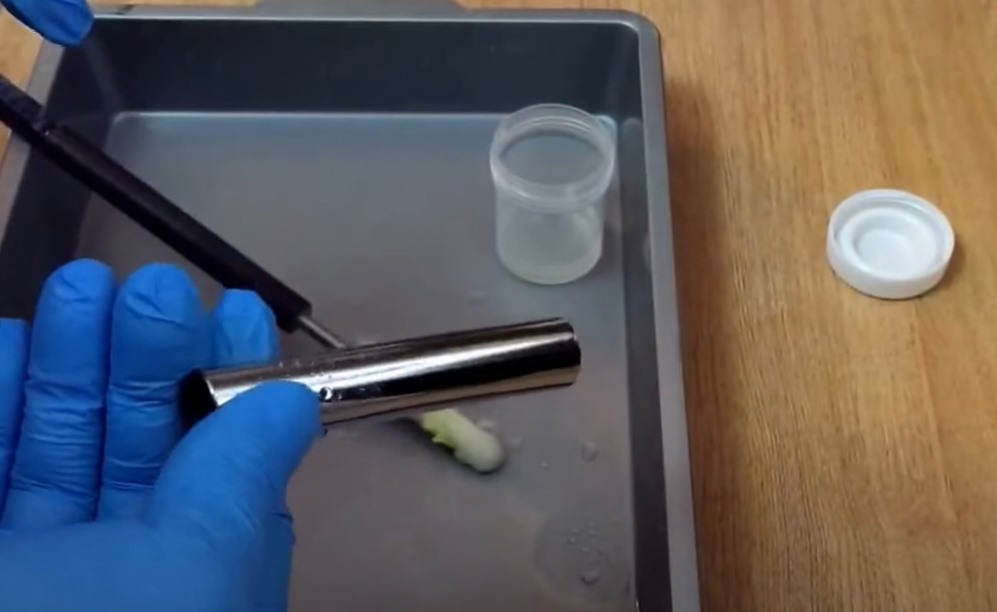

Muriatic acid is also known as hydrochloric acid. It is a corrosive solution that is used for various reasons. It is also used in removal processes after surface treatments or for finish removal. It is a common solution for chrome removal from metal. This solution is taken in 30-40% concentration and added in water. The part is dipped in this solution until the plating is removed fully.

Mechanical Polishing

Special machines are used for removal processes of surface treatments. These machines are useful in metal and plastic finish removal. Abrasive blasting or sand blasting is the technique that is used in this removal processes. This involves abrasion of chrome plating by spraying of tine and fine particles. The tool used is called abrasive blaster. These are staples in auto shops. Because they can completely remove the plating from any material in automobiles.

Electrochemical Dissolution

Chemical solutions are used in electrochemical dissolution. Chromic and sulfuric acid are added to water and this solution is heated to a predetermined temperature for electroplating. It is connected to DC power source and a negative charge is passed through it. The material is connected to positive cathode. And then immersed in the solution. The removal process is carried out until the chrome plating is removed.

Thermal Decomposition

This removal process is consisted of heating material to the temperature 400-450℃. At this temperature range the applied chrome plating starts melting off. This can be removed safely from the material surface as the material cannot be damaged in this process.

Wet Etching

Hydrochloric acid is used as an etchant in wet etching removal process. The surface treatment can be removed easily by dipping the material in the diluted solution of water and hydrochloric acid b of 60/40 ratio. The material is dipped until the finish removal is done completely.

Dry Ice Blasting

Dry ice blasting is a common method for removing plating and coating. It can be used on metal, plastic, and rubber. Removal processes for surface treatment is not an easy process without damaging the material with cold jet system. But it is the best option for sensitive parts and hard chrome processes. The pellets are blasted at metals with high pressure by cold jet systems. It utilizes pellets that used 100cfm at 80psi. and micro pellets use 30cfm at 80psi. Low flow nozzles for micro pellets used 12cfm at 80psi.

Ultrasonic Cleaning

Ultrasonic cleaners use special cleaners for finish removal of surface treatment. It is normally used for sensitive and delicates parts. A high frequency sound wave is used to remove coating that is coating on surface. This causes a vibration in chrome particles at a higher frequency. This breaks the bond between plating and surface and resulted in flaking off the coating. However, this is an expensive process and not suitable for single parts or smaller objects.

Vapor degreasing

Vapor degassing can be used for stripping plating of chrome from metal and other materials. It involves condensing solvent vapor on the material and does not require any scrubbing or water. Instead use vapor for stripping plating or finish removal of surface treatments. Highly toxic chemicals like propyl bromide, perchloroethylene and trichlorethylene are used in degassers. The temperature range is kept between 40-65℃ with pressure of 25amps or less.

Lasers for removal

Laser removal is the safest removal process for stripping plating of surface treatment. As it does not damage the material and does not require any further treatment or cleanup. It can be used for smaller parts or delicate parts. Precision stripping plating is done on whether the area is a few feet or a few inches. Unique geometries can easily be cleaned without being damaged or impacted by laser ablation process.

Electrochemical Corrosion Control (ECC)

The ECC method involves attaching reactive metal to the material with a conducting wire for finish removal. It is carried out in water heaters and the weak metal is called anode. It is a safe method which can also remove rust and corrosion. In this process a thin coating layer of different material is coated on the other metal for various purposes or vice versa.

Remove Chrome Plating Applications

Chrome plating has many applications but sometimes it is damaging the material instead of protecting it when it is torn apart. Therefore, it is necessary to remove it.

How to remove chrome from bumper

Hydrochloric acid is normally used in ratio of 40;60 with water and then car part or bumper is immersed in the solution until the coating is stripped off. Enough time must be given for finish removal.

How to strip chrome wheels

For wheels, chrome stripping is removed by using hydrochloric acid mixing with water. A solution is created with 40% concentration of HCL and then wheel is dipped in the solution. The part is kept immersed in the solution until the coating is removed fully.

How to remove chrome from motorcycle parts

Diluted HCL in water with the ratio of 1/3 is used for chrome removal from motorcycle parts. A heavy-duty metal bucket must be used for this purpose, or a chemical friendly material must be utilized. The part is soaked in the solution for chrome removal.

How to strip chrome for powder coating

Sodium hydroxide mixed with water with ratio of 8-12ounces in 1 gallon water is used for stripping plating for powder coating. The part is soaked in the solution until the stripping plating is done completely.

How to remove chrome from plastic?

chrome stripping is removed by using hydrochloric acid mixing with water. A solution is created with 40% concentration of HCL and then plastic is dipped in the solution. Enough time must be given for finish removal.

How to remove chrome plating from metal

HCL is typically utilized in ratio of 40:60 with water and then metal part is immersed in the solution until the coating is stripped off. Enough time must be given for finish removal.

From aluminum

chrome stripping is removed from aluminum by using HCL mixing with water in 1:3 ratio. A solution is created with 40% concentration of HCL, and then aluminum part is dipped in the solution. Enough time must be given for finish removal.

From brass

Concentrated or diluted HCL can be utilized for chrome removal from brass parts. No electrical current is required in this process. Part is soaked in the solution until the coating is removed.

From copper pipe

Concentrated or diluted HCL can be utilized for chrome removal from copper pipes. There is no requirements of electrical current in this removal process. Part is soaked in the solution until the coating is removed.

From steel wheels

Muriatic acid or HCL is used to remove chrome plating from steels wheel. Concentrated solution is prepared with water and the steel wheels are dipped in the solution until the coating is removed fully.

Pros and Cons of Remove Chrome Plating

Chrome plating has both advantages and disadvantages for various reasons. Both are discussed below:

Advantage

The main advantage of chrome plating is that it is durable. When it is carried appropriately, it can last for many years. It does not require further maintenance or repairing. Therefore, it is a great option for automobiles which needs a protective layer from corrosion and rust.

Other advantage includes that it is not so expensive than other powder coatings and paints. It is cost effective option when the budget is low for extra coating. Furthermore, it does not take much time being coated on material and a fast process which is not time consuming.

It offers outstanding resistance to harsh environments when exposed to chemicals and has high temperatures resistance for metals, plastic, and other materials.

Disadvantages

There are also some disadvantages for chrome plating as well.

If it is not carried out properly, it can peel off and flaked off with time. Bcaue improper application can result in reacting salt water or acid rain or other chemicals.

Furthermore, if it is reacted with certain chemicals or solvent which is hard and slippery, its repairing can be very difficult almost impossible.

if you want to make it last longer, some care must be taken. You could also have to reapply coating which makes it maintenance costs higher than the initial cost.

Precaution must be taken in the removal process as it released fine debris and dust in air which can be toxic and hazardous to health and sometime cause irritation in eyes and lungs. Therefore, proper masks and kits must be wearing during removal process.

Chrome Plating Cost

Chrome plating is a costly process as it also increases the value of material. because it makes the chrome aesthetically pleasing and increases its durability than other coating products. Therefore, the price of chrome plated objects is higher than non-plated ones.

Best Practices and Tips for Successful Chrome Plating Removal

There are many tips and practices that must be known when removing chrome plating. These points are discussed below:

Selecting the right tools and equipment

It is very important to select proper tools and equipment and removal process for surface treatments. As it must not increase the cost of overall project by selecting improper equipment or method. For example, ultrasonic cleaning methods are for smaller objects. It must be kept in mind while using this method that object size must not increase by limitation as it will increase the project cost.

Understanding the material properties of chrome plating

Different materials are plated with chrome. It is important to know the properties of selected material to have good coating result that is durable and can last longer.

Applying the removal method safely and effectively

Precautions must be taken before applying or removing coating. As it releases many toxic particles so proper kits and mask must be worn to remove safely and effectively the coating.

Restoring the surface to its original condition

Stripping plating must be done properly so that the surface can be restored to its original condition. Otherwise, it would be waste of material, cost and time of removal process.

Conclusion

Chrome plating provides corrosion resistant to metal and improves its service life and adds beautification in product. However, there are many reasons that sometimes this coating is not so productive, and advantages and one must remove this. 10 methods to remove the chrome plating are Muriatic acid chrome removal, Mechanical Polishing, Electrochemical Dissolution, Thermal Decomposition, Wet Etching, Dry Ice Blasting, Ultrasonic Cleaning, Vapor degreasing, Lasers for removal and Electrochemical Corrosion Control (ECC). Precaution must be taken in the removal process as it released fine debris and dust in the air which can be toxic and hazardous to health and sometime cause irritation in eyes and lungs. Therefore, proper masks and kits must be worn during the removal process.

China Tuofa's Chrome Plating Service

TUOFA offers great services in custom machining services, 3D printing, sheet metal custom and surface finishes. Different surface finishing services are offered here such as removing or reshaping finishing and adding or altering finishing. If you are looking for a reliable service provider for chrome plating and removing, then Tuofa offers best services and products. For more information, please contact info@tuofa-cncmachining.com

FAQs about Chrome

How to age chrome?

Chrome can be aged by using scouring pad or by submerging the chrome plated object in muriatic acid.

To achieve a dull look for your chrome, you can use a scouring pad, or you can submerge the chrome in a solution of muriatic acid. If you follow the correct steps and use the right materials, dulling your chrome is easy to do.

How to strip chrome?

Abrasive scrubbing can strip the chrome plating easily. Baking soda and different cleaners that are used in households can also be used for rubbing and removing chrome plating.

How to chrome delete car?

Muriatic acid or HCL is used to remove chrome plating from car parts. As it is mixed with water with 40:60 ratio.

Does oven cleaner remove chrome plating?

Yes, oven cleaners used in household can remove chrome plating by rubbing it over the object with soft cloth.

How to remove chrome plating at home?

Baking soda mixed with water can remove chrome plating. Oven cleaner can also be used by rubbing it with soft cloth.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

CNC Motorcycle Parts and Bike Parts: Advantages and Price

CNC Motorcycle Parts and Bike Parts: Advantages and Price