Precision Stamping Medical Devices - The Best China Sheet Metal Manufacturer

Services: OEM / ODM CNC Precision Sheet Metal Fabrications

Process: stamping service + Laser cutting + Metal Bending + Deburrs

Surface treatment: Polishing, PVD, Anodizing

Equipment: Laser cut machine and bend machine

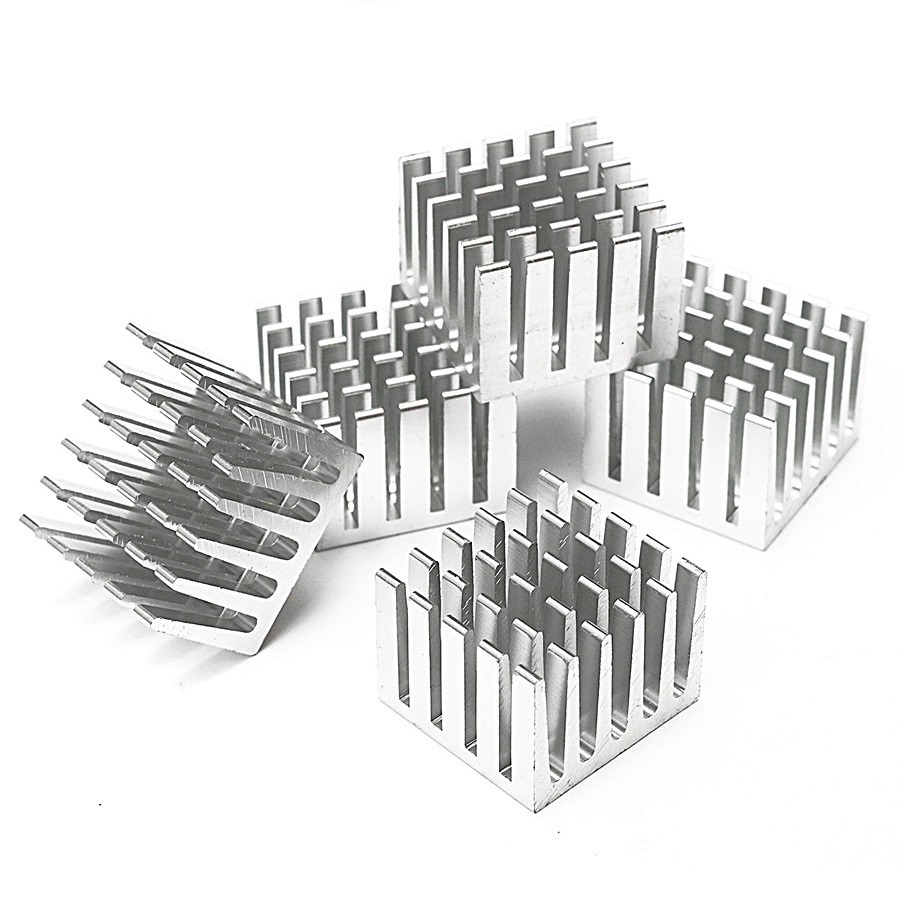

Tuofa Technologies we are constantly developing our high-speed CNC machining parts services to meet the needs of our long-term customer base. We strategically leverage our expertise and experience with our state-of-the-art CNC Machining Centers to deliver modified extrusion or custom bonded fin heatsinks that our customers rely on.

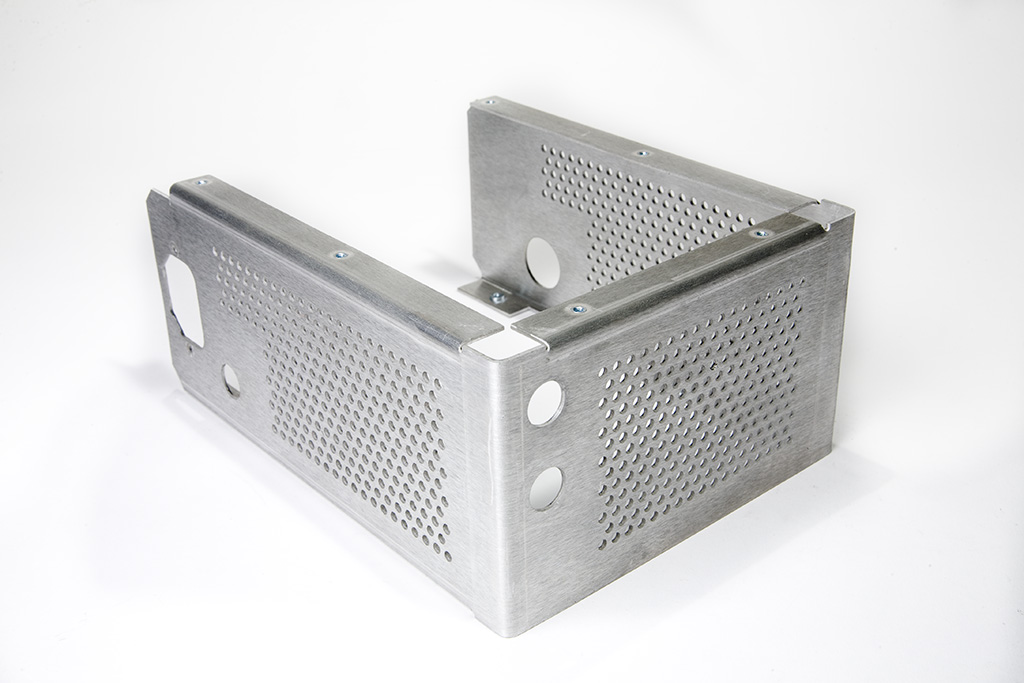

Tuofa is a full-service sheet metal fabricator with the ability to provide design assistance, prototypes, pilot & production runs to your specs. We also make full products complete to print, including plating, painting, silk screening, polishing and assembly.Online precision metal stamping for medical devices is one of the types of parts we produce in small batches, with customers mostly from North America and Western Europe.

15 years of making sheet metal into high end commercial and industrial assemblies and parts means we are not newbies. Our job-shop fabricates assorted materials including steel, stainless steel & aluminum with state-of-the-art equipment from laser cutting to welding.

Sheet Metal Fabrication offers a full range of manufacturing services producing custom made sheet metal parts and assemblies for your OEM products.

Metal Stampings for LED lamps & Medical Devices

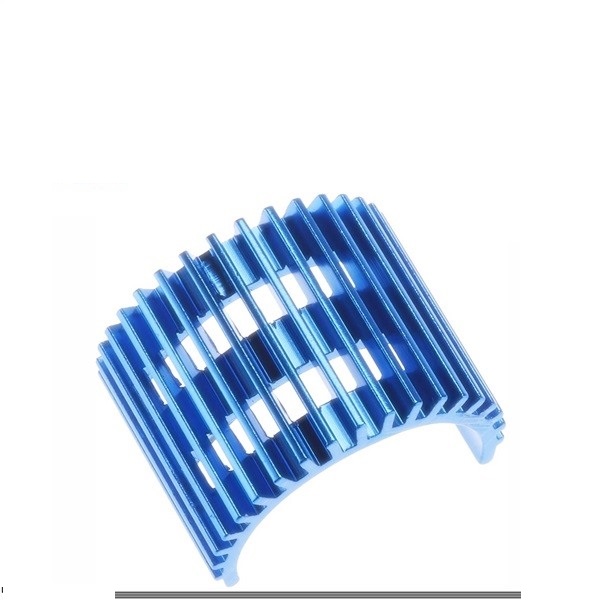

An LED is performance, similar to any other semiconductor device, is temperature sensitive. Higher temperature causes degradation in life and light emittance of the LED. ATS offers a complete line of high-performance cooling solutions based on its patented maxiFLOW™ technology to cool LED based round down lights. These heat sinks enable designers to cool their LED lights for highest performance and efficiency.

The antibacterial and corrosion-resistant stamping parts based on medical devices can wrap the stamping plate by arranging the upper plate body and the lower plate body with antibacterial ability outside the existing stamping plate, so that the stamping plate can have efficient antibacterial ability and anti-corrosion ability. At the same time, a corrosion-resistant lining is arranged at the position of the installation hole or through hole, which can seal the hole and avoid the problem of corrosion and bacterial growth at the hole position.

Aluminum Extrusion Heat Sink Features & Benefits

Designed for high-performance convection cooling of high heat flux LEDs.

Base includes inner and outer threads for attachment of lens mounts, brackets, and other hardware.

Each STAR series extrusion length is made from lightweight, anodized aluminum for maximum thermal performance.

Customizable to any length. Check our CNC machined parts.

Precision Sheet Metal Factory Custom Stamping Parts

we are been honing our precision metal core heatsink fabrication capabilities for more than 15 years. Our processes are cost-competitive while offering superior quality products and higher yields. As a result, we are now recognized as a leading heatsink fabricator for the printed circuit board and aerospace industries.

Our metal core fabrication processes utilize a high-speed multi-spindle CNC drilling and routing machines along with specialized and proprietary fiber-filling techniques. Our advanced capabilities can maintain tolerances of ±.0002” with a repeatability accuracy of ±.0001” on parts up to 30” long and up to 20” wide.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Related Suggestion

Related Suggestion

Dec 18,2021

Dec 18,2021

Tel

Tel

Email

Email

Address

Address