Unleash the Potential of Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy with Tuofa China's Precision CNC Machining

At Tuofa China, we understand your quest for excellence, and we're here to empower you with the exceptional capabilities of Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy (UNS R53400) custom CNC machined components.

Chemical Composition of Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy UNS R53400

Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy (UNS R53400) is a low-alloy titanium material known for its exceptional strength, corrosion resistance, and biocompatibility. Its chemical composition is carefully controlled to achieve these desirable properties:

| Element |

Weight Percent (%) |

| Titanium (Ti) |

Balance |

| Molybdenum (Mo) |

0.2 - 0.4 |

| Nickel (Ni) |

0.6 - 0.9 |

| Iron (Fe) |

0.3 max |

| Oxygen (O) |

0.25 max |

| Other (individual impurities) |

0.1 max |

Note: The weight percentages for molybdenum (Mo) and nickel (Ni) are specified as ranges, while the weight percentages for iron (Fe) and oxygen (O) are maximum limits. This indicates that the composition of these elements can vary within these ranges while still meeting the specifications for Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy.

The precise balance of these elements in Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy contributes to its unique properties:

-

Molybdenum (Mo): Enhances strength and corrosion resistance, particularly in reducing environments.

-

Nickel (Ni): Further improves corrosion resistance, especially in chloride-containing media.

-

Iron (Fe): Controlled levels of iron contribute to the alloy's overall strength and hardenability.

-

Oxygen (O): While controlled oxygen levels are important for strengthening the alloy, excessive oxygen can impair its ductility and toughness.

The carefully controlled chemical composition of Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy makes it a valuable material for various demanding applications, including aerospace components, medical implants, chemical processing equipment, and marine components.

Additional Information

-

UNS Designation: UNS R53400 is the Unified Numbering System (UNS) designation for Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy.

-

ASTM Standards: This alloy is also covered by ASTM standards, including ASTM B265, ASTM B337, ASTM B338, ASTM B348, and ASTM B381.

Why Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy?

Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy stands out as a premier choice for demanding applications due to its remarkable properties:

-

Exceptional Strength: Boasting superior tensile and yield strength, it's ideal for weight-critical applications where every ounce counts.

-

Unmatched Corrosion Resistance: Withstands harsh environments, including seawater, acids, and alkalis, ensuring long-lasting performance.

-

Outstanding Biocompatibility: Compatible with human tissue, making it suitable for medical implants and surgical instruments.

-

Enhanced Formability: Can be shaped into intricate geometries through various manufacturing processes, enabling complex designs.

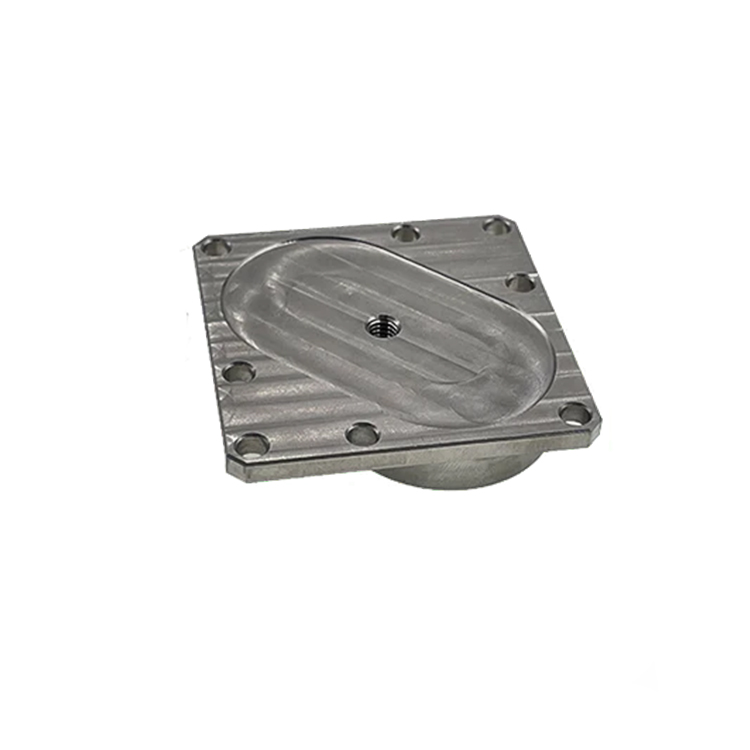

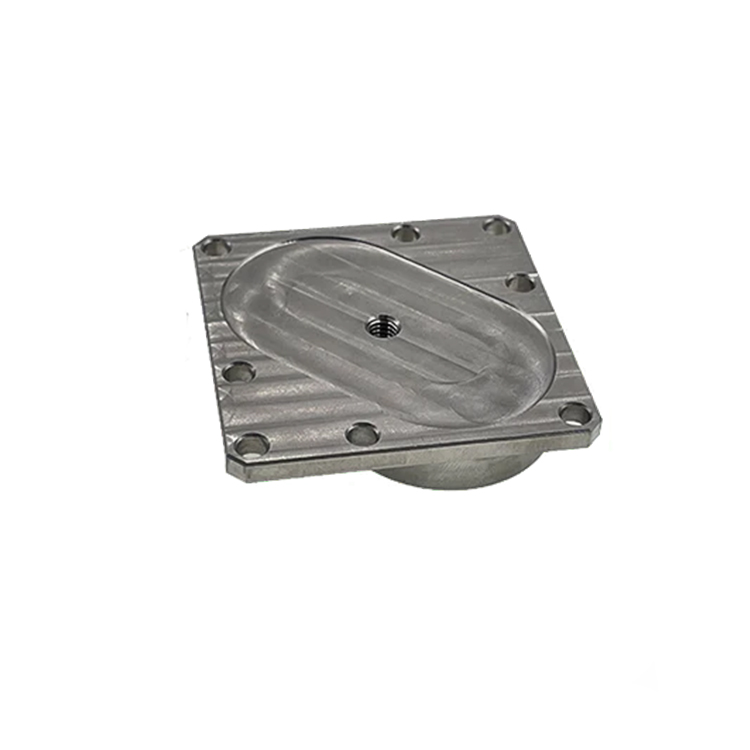

Unleash the Power of CNC Machining with Tuofa China

CNC machining, our expertise of choice, transforms Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy into high-precision components that meet your most stringent requirements:

-

Tight Tolerance Precision: Achieve precise dimensions and tolerances up to ±0.0002" (0.005 mm) for critical applications.

-

Complex Geometry Mastery: Manufacture components with intricate shapes, thin walls, and tight corners with unmatched precision.

-

Diverse Surface Finishes: Deliver a range of surface finishes, from smooth and polished to textured and matte, to meet specific requirements.

-

Material Versatility: Handle various forms of Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy, including bars, plates, and forgings, for optimal machinability.

Tuofa China: Your One-Stop Solution for Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy CNC Machined Parts

With over two decades of experience in CNC machining, specializing in titanium alloys, Tuofa China is your trusted partner for precision-engineered components:

-

Aerospace Components: Aircraft structural components, engine parts, landing gear systems

-

Medical Implants: Medical implants, surgical tools, dental prosthetics

-

Chemical Processing Components: Pump and valve components, reactor vessels, heat exchangers

-

Marine Components: Marine hardware, underwater equipment, desalination systems

-

Oil and Gas Components: Downhole tools, pressure vessels, wellhead components

How We Empower You

-

Expert Consultation: Our team of engineers collaborates closely with you to understand your specific requirements and provide expert design and material selection guidance.

-

Optimized Design Solutions: We leverage our extensive knowledge of Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy and CNC machining to optimize your designs for manufacturability, performance, and cost-effectiveness.

-

Seamless Manufacturing: Our state-of-the-art CNC machining facilities and stringent quality control procedures ensure consistent precision and adherence to your specifications.

-

On-Time Delivery: We understand the importance of meeting project deadlines and commit to delivering your components on time, every time.

Experience the Tuofa China Difference

Contact us today to discuss your Titanium Grade 12 Ti-0.3Mo-0.8Ni Alloy CNC machining needs and experience the Tuofa China difference. We are confident that we can exceed your expectations and help you bring your most innovative designs to life.

Tuofa China: Your Precision Engineering Partner

Website: www.tuofa-cncmachining.com

Email: info@tuofa-cncmachining.com

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Related Suggestion

Related Suggestion

Dec 18,2021

Dec 18,2021

Tel

Tel

Email

Email

Address

Address