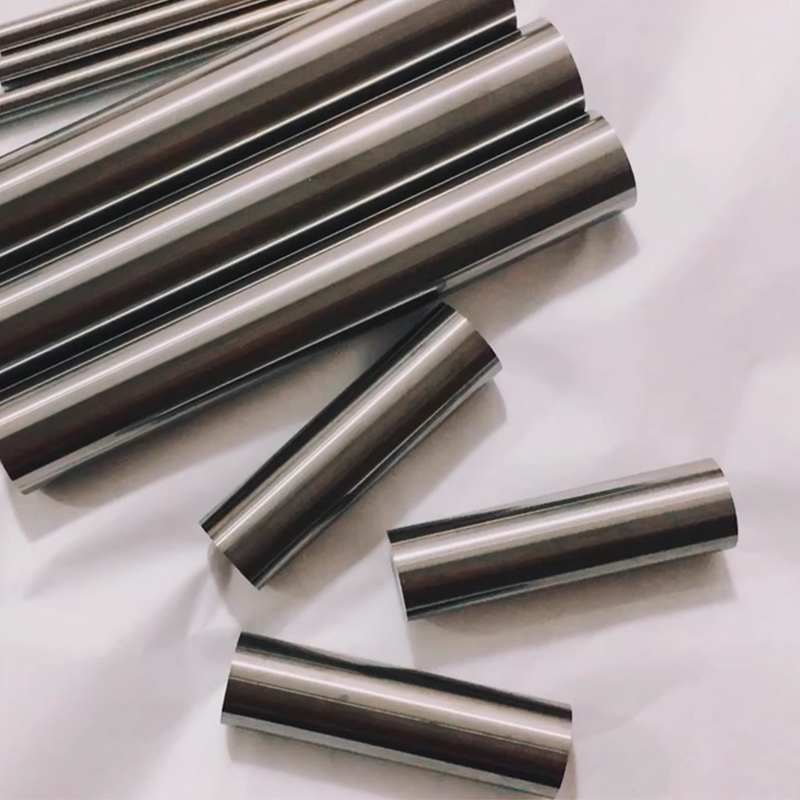

At Tuofa CNC Machining Supplier, we specialize in the precision CNC machining of Titanium Grade 13 Ti-13V-11Cr-3Al Alloy UNS R58010, a high-strength beta titanium alloy. This alloy is renowned for its excellent ductility, corrosion resistance, and mechanical properties, making it ideal for applications where strength-to-weight ratio is critical. Our state-of-the-art facilities and skilled engineers ensure that every component is manufactured to the highest standards.

Ti-13V-11Cr-3Al Titanium Alloy Key Features & Benefits

- High Strength-to-Weight Ratio: Offers superior strength with a lightweight profile, ideal for aerospace and missile applications.

- Corrosion Resistance: Excellent resistance to reducing acids and various corrosive environments.

- Ductility: Capable of being cold worked for further enhancement of mechanical properties.

- Heat Treatable: Can be heat treated to achieve a wide range of strength levels.

Chemical Composition

Our Titanium Grade 13 alloy is meticulously crafted with the following chemical composition:

- Vanadium (V): 12.5 - 14.5%

- Chromium (Cr): 10-12%

- Aluminum (Al): 2.5 - 3.5%

- Iron (Fe): Max 0.35%

- Oxygen (O): Max 0.17%

- Carbon (C): Max 0.05%

- Nitrogen (N): Max 0.05%

- Hydrogen (H): Max 0.025%

- Titanium (Ti): Balance

Physical Properties

| Properties |

Metric |

Imperial |

| Density |

4.84 g/cm³ |

0.175 lb/in³ |

Mechanical Properties

| Properties |

Metric |

Imperial |

| Tensile Strength |

1276 MPa |

185068 psi |

| Yield Strength |

1207 MPa |

175060 psi |

| Poisson’s Ratio |

0.304 |

0.304 |

| Elastic Modulus |

101.4 GPa |

14706 ksi |

| Elongation at Break |

8% |

8% |

| Hardness (HRC) |

40 |

40 |

Thermal Properties

| Properties |

Conditions |

| Thermal Expansion Coefficient |

9.4 x 10⁻⁶/°C |

Fabrication and Heat Treatment

- Machinability: Grade 13 can be machined using slow speeds, high coolant flow, and high feed rates. Tooling should be performed using tungsten carbide or cobalt type high-speed tools.

- Forming: Capable of both hot and cold forming.

- Welding: Rated as good.

- Annealing: Full annealing can be performed by heating to 788°C (1450°F) for 15 min and then air cooled.

- Forging: Can be performed at 1065-1176°C (1950-2150°F).

- Hot Working: Enhances the overall ductility of the material.

- Cold Working: Features are similar to that of a moderately tempered austenitic stainless steel. Post-work annealing is recommended.

Applications

Our Titanium Grade 13 alloy is used in a variety of applications due to its unique properties:

- High-strength airframe components such as wire springs

- Aerospace and missile applications

- Springs

Why Choose Tuofa CNC Machining Supplier

- Expertise: Over a decade of experience in CNC machining and metal stamping.

- Technology: Utilizing the latest CNC machining technology for precise and efficient production.

- Customer Focus: Committed to delivering exceptional service and support.

Contact Information

For more information or to discuss your next project, please contact us:

- Email: info@tuofa-cncmachining.com

- Phone: 8613713980135

- Website: www.tuofa-cncmachining.com

- Address: 107, Huanguan South Road, Longhua District, Shenzhen, CN, 518110

Conclusion: Titanium Grade 13 Ti-13V-11Cr-3Al Alloy UNS R58010 is a high-performance material suitable for a range of demanding applications. Tuofa CNC Machining Supplier is dedicated to providing precision CNC machining services that meet the rigorous requirements of our clients. With our expertise and state-of-the-art technology, we ensure that every component is manufactured to the highest standards of quality and precision.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Related Suggestion

Related Suggestion

Dec 18,2021

Dec 18,2021

Tel

Tel

Email

Email

Address

Address