Tuofa CNC Machining Factory: Your Precision Invar 36 CNC Machined Components Partner

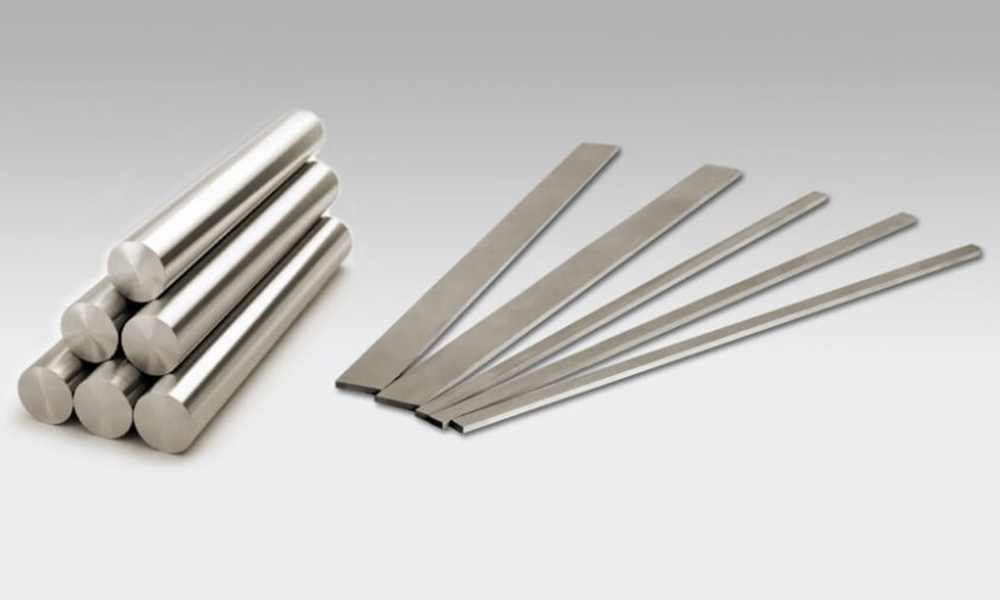

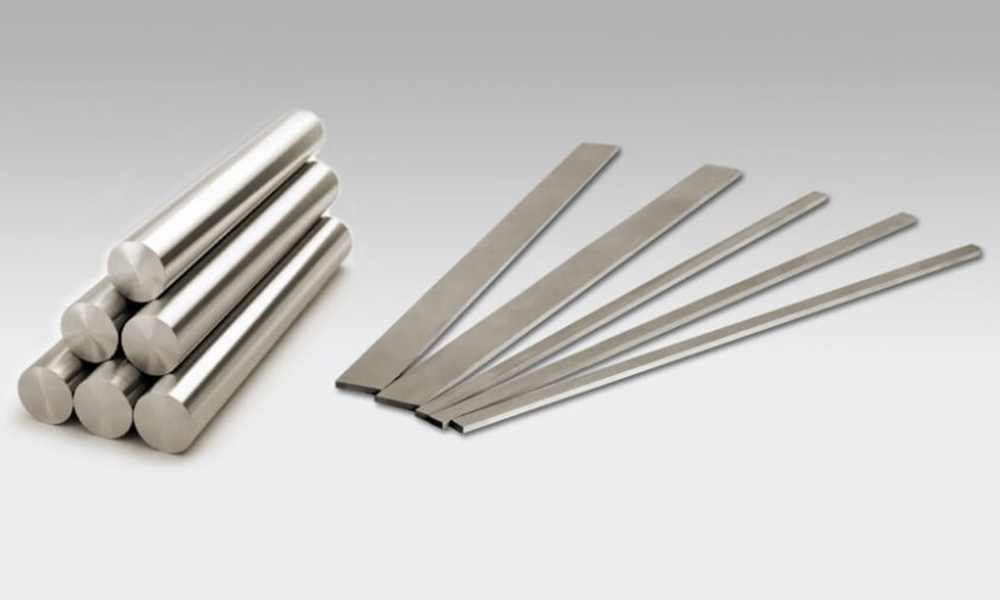

At Tuofa CNC Machining Factory, we specialize in precision CNC machining of Invar 36 (N06330), a nickel-iron alloy renowned for its exceptional dimensional stability, low thermal expansion coefficient, and resistance to extreme temperatures. Our expertise and advanced CNC milling capabilities enable us to manufacture intricate Invar 36 components that meet the most demanding requirements across various industries.

Why Choose Invar 36 (N06330) CNC Machined Parts?

Invar 36 (N06330) is an ideal material for a wide range of applications due to its unique properties:

1. Exceptional Dimensional Stability:

Low Thermal Expansion Coefficient: Invar 36 exhibits an exceptionally low thermal expansion coefficient of 1.65 x 10^-6/°C (3.0 x 10^-6/°F), meaning it expands or contracts minimally with temperature changes. This property makes it ideal for applications where precise dimensions are critical, even under extreme temperature fluctuations.

2. High Strength and Durability:

Tensile Strength: Invar 36 possesses a tensile strength of up to 240 MPa (35,000 psi), ensuring the reliability and longevity of machined components.

Ductility: Invar 36 exhibits good ductility, allowing it to be formed into complex shapes without cracking or breaking.

Toughness: Invar 36 has a fracture toughness of 27 J/cm^2 (24 ft-lb/in), making it resistant to impact and fatigue.

3. Corrosion Resistance:

Resistance to Seawater, Acids, and Alkalis: Invar 36 exhibits excellent corrosion resistance in various environments, including seawater, acids, and alkalis.

4. Excellent Machinability:

Precise CNC Machining: Invar 36 can be precisely machined using CNC techniques, allowing for the creation of complex geometries and intricate features.

Our Invar 36 (N06330) CNC Turning and CNC Milling Services

Tuofa CNC Machining Factory offers comprehensive Invar 36 (N06330) CNC milling services, catering to diverse customer needs:

1. Custom CNC Milled Parts:

Tailored Designs: We produce custom Invar 36 components based on your specific design requirements and dimensional tolerances.

Tight Tolerances: We achieve tolerances of up to ±0.0002" (0.005 mm) for critical dimensions, ensuring precise fit and optimal performance.

2. Precision Milling:

State-of-the-Art CNC Milling Machines: Our modern CNC milling machines ensure precise machining of Invar 36 parts, guaranteeing exceptional accuracy and surface finish.

Experienced Machinists: Our team of experienced machinists possesses the expertise to handle even the most challenging Invar 36 machining tasks.

3. Surface Finishing:

Anodizing: We offer anodizing in various colors to enhance corrosion resistance, surface hardness, and aesthetics.

Plating: We provide plating services, including nickel plating, chrome plating, and zinc plating, to further enhance corrosion resistance and surface properties.

Polishing: We offer polishing services to achieve a smooth, mirror-like finish for aesthetic appeal and improved surface finish.

Why Choose Tuofa CNC Machining Factory?

At Tuofa CNC Machining Factory, we are committed to providing our customers with the highest quality Invar 36 (N06330) CNC machined parts and exceptional service:

1. Unmatched Precision:

Advanced CNC Machines: Our state-of-the-art CNC machines ensure unmatched precision and adherence to tight tolerances.

Rigorous Quality Control: We implement rigorous quality control procedures throughout the manufacturing process to guarantee consistent quality and meet your specifications.

2. Durability and Reliability:

High-Quality Materials: We use only the highest quality Invar 36 materials to ensure the durability and reliability of our components.

Stringent Testing: We perform stringent testing on all Invar 36 components to ensure they meet our high standards for performance and reliability.

3. Cost-Effectiveness:

Efficient Manufacturing Processes: We optimize our manufacturing processes to offer competitive pricing while maintaining the highest quality standards.

Applications of Invar 36 (N06330) CNC Machined Parts

Invar 36 (N06330) CNC machined parts are widely used in various industries due to their exceptional properties:

1. Aerospace Industry:

Satellite Components: Invar 36 components are employed in satellite structures and components due to their dimensional stability and ability to withstand extreme temperatures in space.

Aircraft Components: Invar 36 parts are used in aircraft engines and structural components due to their low thermal expansion coefficient, ensuring precise dimensions and reliable performance.

2. Electronics Industry:

Electronic Packaging: Invar 36 components are utilized in electronic packaging due to their dimensional stability and ability to maintain precise dimensions in harsh environments.

Precision Electronic Components: Invar 36 parts are used in precision electronic components, such as resistors and capacitors, due to their low thermal expansion coefficient and high stability.

3. Scientific Instrumentation:

Measuring Devices: Invar 36 components are employed in measuring devices, such as rulers and gauges, due to their dimensional stability and ability to maintain precise measurements.

Scientific Instruments: Invar 36 parts are used in scientific instruments, such as telescopes and microscopes, due to their low thermal expansion coefficient and high precision.

4. Oil and Gas Industry:

Pipelines and Equipment: Invar 36 components are used in oil and gas pipelines and equipment due to their corrosion resistance and dimensional stability.

Downhole Tools: Invar 36 parts are employed in downhole tools, such as drilling equipment and wellbore casing, due to their ability to withstand extreme temperatures and pressures.

5. Medical Devices:

Surgical Implants: Invar 36 components are utilized in surgical implants, such as joint replacements and dental prosthetics, due to their biocompatibility and dimensional stability.

Medical Imaging Equipment: Invar 36 parts are used in medical imaging equipment, such as MRI scanners and X-ray machines, due to their low thermal expansion coefficient and high precision.

Case Studies: Real-World Applications of Invar 36 CNC Machined Parts

To further illustrate the versatility and performance of Invar 36 CNC machined parts, consider these real-world applications:

Case Study 1: Invar 36 Telescope Components

In a collaborative project with a renowned astronomical observatory, Tuofa CNC Machining Factory manufactured precision Invar 36 components for a new telescope assembly. The Invar 36 components, including telescope mirrors, mounts, and structural supports, were crucial in ensuring the telescope's exceptional stability and dimensional accuracy, even under extreme temperature fluctuations.

Case Study 2: Invar 36 Medical Implants

Working closely with a leading medical device manufacturer, Tuofa CNC Machining Factory produced intricate Invar 36 components for advanced joint replacement implants. The Invar 36 components, including joint stems, cups, and spacers, were designed to provide long-lasting performance, biocompatibility, and precise fit for patients undergoing joint replacement surgeries.

Case Study 3: Invar 36 Oil and Gas Pipeline Components

In partnership with a major oil and gas company, Tuofa CNC Machining Factory fabricated Invar 36 components for a critical oil pipeline project. The Invar 36 components, including pipeline segments, valves, and fittings, were essential in ensuring the pipeline's integrity and resistance to corrosion and extreme temperatures.

These case studies demonstrate the diverse applications and remarkable performance of Invar 36 CNC machined parts across various industries. Tuofa CNC Machining Factory is committed to providing customers with the highest quality Invar 36 components and expert engineering services to meet the most demanding requirements.

Contact Us for Your Invar 36 (N06330) CNC Milling and CNC Turning Needs

At Tuofa CNC Machining Factory, we are dedicated to providing our customers with exceptional Invar 36 (N06330) CNC milling and CNC turning services and high-quality components. Contact us today to discuss your specific requirements and experience the Tuofa difference.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Related Suggestion

Related Suggestion

Dec 18,2021

Dec 18,2021

Tel

Tel

Email

Email

Address

Address