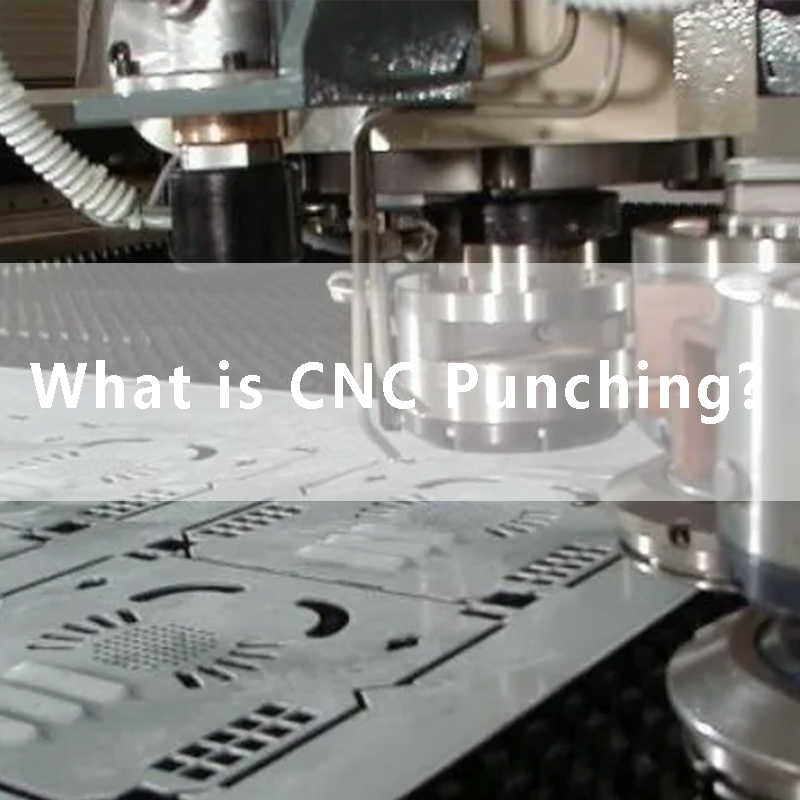

What is CNC Punching? Applications, Operators, and Technology

Jul 24,2024

Jul 24,2024

Whether you're an experienced professional in the manufacturing industry or a mechanical designer seeking detailed insights, this blog post will provide valuable, practical, and correct advice on CNC punching. We will delve into its extensive applications across various industries, the role of CNC punch operators, the distinctions between punching and stamping, and the critical role of CNC in the defense sector. Additionally, click here to learn the top 10 CNC machining parts manufacturers in China. Let's explore the intricacies of CNC punching. Understand how this technology revolutionizes modern manufacturing.

What is CNC Punching Used For?

CNC punching is a pivotal process in modern manufacturing, enabling the creation of precise holes and shapes in sheet metal. Its applications span across numerous industries due to its versatility and precision. Let's look at some key sectors where CNC punching is extensively utilized.https://www.tuofa-cncmachining.com/

|

Industry |

Applications |

Benefits |

|

Automotive |

Brackets, panels, various components |

High precision, durability |

|

Aerospace |

Lightweight, durable components |

Meets stringent standards |

|

Construction |

Structural elements, decorative panels |

Ideal for complex shapes |

|

Electronics |

Enclosures, mounting plates, heat sinks |

Precision, repeatability |

|

HVAC |

Ventilation grilles, ductwork components |

Optimal airflow, system performance |

|

Appliances |

Various integral parts |

Consistent quality in high volumes |

|

Defense (Weapons) |

Firearms, artillery, missile parts |

Paramount precision |

|

Defense (Vehicles) |

Structural, functional parts for military vehicles |

Robustness, durability |

|

Defense (Aerospace) |

Aircraft, drone components |

Lightweight, durable |

|

Defense (Support) |

Tools, equipment for military operations |

Versatility |

Automotive

In the automotive industry, CNC punching is used to fabricate parts such as brackets, panels, and various components. These parts require high precision and durability, which CNC punching can efficiently deliver.

Aerospace

The aerospace industry benefits from CNC punching. It enables the production of lightweight and durable components. The precision offered by CNC punching is critical. It is essential for manufacturing parts that meet stringent aerospace standards.

Construction

CNC punching is employed in the construction sector. It is used to create structural elements and decorative panels. The ability to punch complex shapes and patterns makes it ideal. It is perfect for architectural and structural applications.

Electronics

In electronics, CNC punching is used to manufacture enclosures, mounting plates, and heat sinks. The precision and repeatability of CNC punching ensure that electronic components fit perfectly. This enhances performance and reliability.

HVAC

The HVAC industry uses CNC punching to produce ventilation grilles and ductwork components. The efficiency and accuracy of CNC punching help in creating parts. These parts facilitate optimal airflow and system performance.

Appliances

For household and industrial appliances, CNC punching creates various parts. These parts are integral to the appliance's functionality and design. The repeatability of CNC punching ensures consistent quality across high production volumes.

What is a CNC Punch Operator?

A CNC punch operator is a skilled technician responsible for managing the CNC punching process. Their expertise ensures that the punching operations are conducted with precision and efficiency. Here are the primary responsibilities of a CNC punch operator:

Machine Setup

The operator is responsible for installing and calibrating the necessary tools and dies. This setup is crucial. It ensures that the machine operates correctly. It produces parts with the desired specifications.

Programming

CNC punch operators input design specifications into the machine's computer. This programming step translates design blueprints. It turns them into executable instructions for the CNC punching machine.

Operation

During operation, the CNC punch operator oversees the punching process. They ensure that the machine is running smoothly and that the punched parts meet quality standards.

Maintenance

Routine checks and maintenance are part of the operator's duties. Regular maintenance ensures that the machine operates efficiently. It reduces the risk of breakdowns.

What is the Difference Between Punching and Stamping CNC?

Both punching and stamping involve shaping metal. However, they differ significantly in their techniques and applications.

Punching

Punching uses a punch press to create holes or cutouts by shearing the metal. This process is suitable for simpler shapes and repetitive tasks. It's highly efficient for producing large quantities of identical parts.

Stamping

Stamping involves more complex operations like bending, embossing, and coining using a die. It can form intricate shapes in one or multiple stages, making it suitable for detailed parts. Stamping is often used for parts that require multiple shaping processes.

What is CNC in Defence?

In the defense industry, CNC machining, including CNC punching, plays a critical role. It is essential for manufacturing precision components. The defense sector demands high precision and reliability. CNC technology can consistently provide this.

Weapon Systems

CNC punching is used to create parts for firearms, artillery, and missiles. The precision required for these components is paramount. CNC punching delivers the necessary accuracy.

Vehicles

For military vehicles, CNC punching produces structural and functional parts. These parts need to be robust and durable. They must withstand harsh conditions. CNC punching ensures they meet these requirements.

Aerospace

In military aerospace applications, CNC punching manufactures components for aircraft and drones. The lightweight yet durable parts created through CNC punching are essential. They are crucial for optimal performance.

Support Equipment

CNC punching is also used to create tools and equipment for various military operations. The versatility of CNC punching allows for the production of a wide range of support equipment.

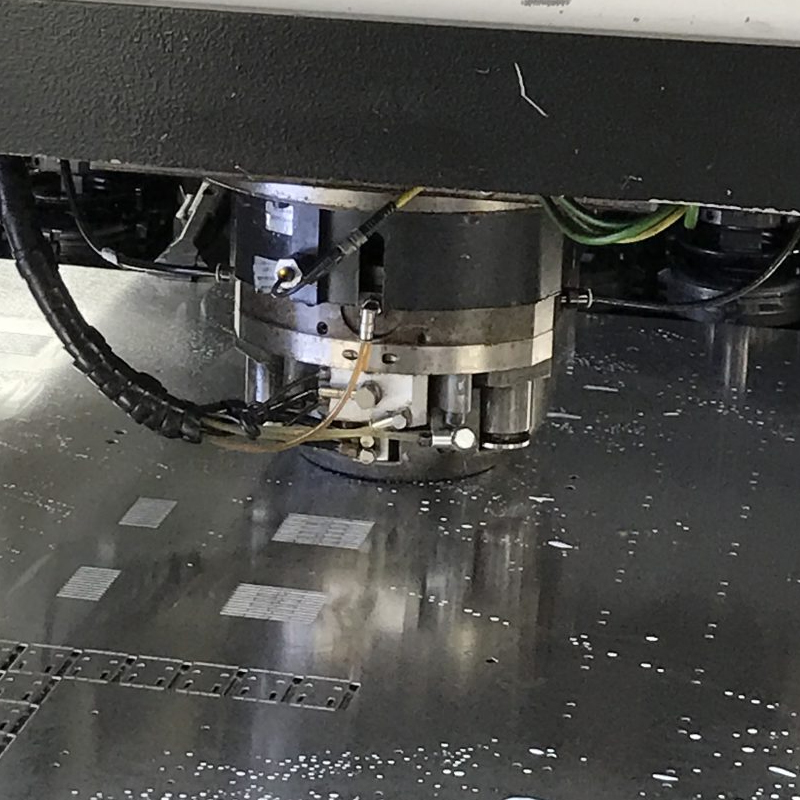

How Does a CNC Punching Machine Work?

CNC punching machines operate by moving sheet metal in an 'X' (left and right) direction. They also move it in a 'Y' (in and out) direction under a punching ram. The process is controlled by a computer program. This ensures precise positioning of the metal sheet. Here's a detailed look at the operation of a CNC punching machine:

Precision Movement

The machine's computer program controls the movement of the sheet metal. It ensures that the metal is positioned accurately under the punching ram. This precise movement is essential for creating accurate shapes and holes.

Punching Ram

The punching ram moves up and down to punch holes or cutouts in the sheet metal. The ram's movement is synchronized with the sheet metal's positioning to ensure accurate punching.

Tooling

CNC punching machines are equipped with various tools and dies. These tools can be quickly changed to accommodate different shapes and sizes. This enhances the machine's versatility.

Efficiency

CNC punching machines are designed for high repeatability and minimal waste. This efficiency is critical for large-scale production, where consistency and cost-effectiveness are essential.

What is a CNC Punch Press?

A CNC punch press automates the punching process using computer numerical control. This machine is equipped with various tools and dies to punch holes, cutouts, and shapes in sheet metal. Here's an overview of the key features of a CNC punch press:

Versatility

A CNC punch press can handle different materials and thicknesses, making it suitable for a wide range of manufacturing needs. The ability to switch tools quickly allows for diverse punching operations.

Automation

The automation provided by CNC technology reduces the need for manual intervention. This automation enhances efficiency and ensures consistent quality across production runs.

Precision

CNC punch presses deliver high precision. This precision is essential for creating parts that meet exact specifications. It is critical for industries like aerospace and defense. In these sectors, accuracy is paramount.

What is a CNC Turret Punching Machine?

A CNC turret punching machine features a rotating turret that holds multiple tools. This design allows for rapid tool changes. It enables multiple punching operations without manual intervention. Here are the advantages of using a CNC turret punching machine:

Efficiency

The rotating turret enables quick tool changes. This reduces setup times. It enhances production efficiency. This feature is particularly beneficial for high-volume production.

Versatility

With multiple tools readily available, a CNC turret punching machine can perform various punching operations. This capability enhances its versatility and efficiency.It can do this in a single setup. This versatility streamlines the manufacturing process.

Reduced Downtime

The ability to switch tools quickly minimizes downtime. This ensures that production runs smoothly. It also enhances efficiency.This reduced downtime translates to increased productivity.

Conclusion

Understanding CNC punching and its applications provides valuable insights into modern manufacturing processes. Custom CNC Machining Service in China offers precise and efficient solutions across various industries. These range from automotive to electronics. Tuofa company by leveraging the capabilities of CNC punching, manufacturers can achieve high precision. They also benefit from repeatability and cost-effectiveness in their production processes.Get A Quote | Custom CNC Parts | Tuofa.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is Burrs in Machining: Complete Guide 2025

What is Burrs in Machining: Complete Guide 2025