What is CNC Lathe | Turning Parts Inc

Aug 01,2022

Aug 01,2022

Learn more about CNC turning parts and CNC lathe operation in this article. The guide also provides useful information on producing your parts with precision. Read on to broaden your horizons.

CNC is a type of CNC machining. This machining process is where the final material is spun at high speed. During this process, a cutting tool is used against the material spun to shave it away. All the parts used to make computer numerical control devices are called computer turning parts. Therefore, CNC turning parts are materials or objects that make the CNC Lathe work efficiently while making precise measurements. Production of CNC turning is different from CNC milling techniques. CNC turning parts are produced using the earliest and simplest manufacturing preciseness. The process works on the same principle as a CNC lathe. A lathe is an ancient human tool that dates back to ancient Egypt.

CNC is an abbreviation for computer numerical control. It is a wide term for manufacturing processes subjected to computer control designs. Its parts are developed and specifically designed using computer aid design. The computer aid design is in a file format and acts as the base for the computer numerical control. It controls the CNC lathe and is responsible for all other processes such as cutting and directing using some unique line of codes.

What is turning operation in CNC?

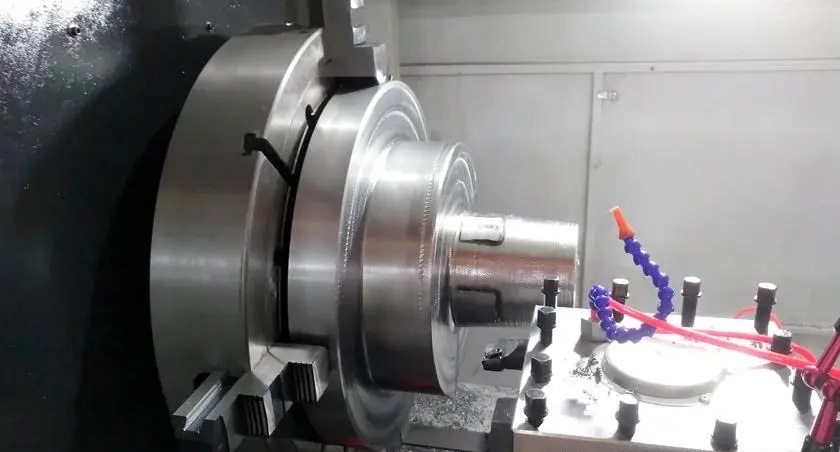

Turning operation in CNC Lathe is the manufacturing process where material bars are helped firmly by chunks and rotated. Another material is fed to the bacterial bars, which helps the chuck remove other parts until you have the desired shape. CNC machine features a turret with tooling codes programmed to move and act agents the material held at the chunk. The unwanted material is removed from the chunk, and the desired shape is produced according to the program’s requirements. Turning operation in CNC can also be referred to as subtraction machining since materials are eliminated. If the center of the CNC device has both tunning and milling properties, the turning operation can be stooped to allow milling to acquire desired shapes.

CAD code and g-code

This section can be simplified into two processes, i.e.,

- Creating a representation of the part in CAD using a digital format.

- Using the CAD files to create code reforestation.

These two steps can be merged or can be carried out individually. The first and direct way is to use a CAD program to create a representation of flies and then feed it into the production unit. The engineer creates a g-code and m-code for turning operation in the production unit.

The second way is using CAD-CAM software that allows the engineer to test the productibility of the designed part. Simulating tools can show the entire process, from raw material to final product.

This process can also be used by creating the g-codes manually. For instance, it's impossible to generate codes from a two-dimensional drawing. In such cases, you only have two choices – producing a three-dimensional model or writing the codes manually. Sometimes the engineer will be forced to go the manual way because not all CAM programs have everything ready for you.

Setting Up the CNC Lathe

This is the testing process of the turning operation, which involves setting up the CNC machine. In this section, the role of the engine is displayed. Although most CNC lathes have everything in place, the engineer plays a vital role.

Setting up the CNC turning center

- Cutting off the power supply if it is on.

- Securing sufficient size in the chuck.

- Lading the turret.

- Calibration and uploading of the prepared program depending on your requirements.

- Manufacturing the turned sections.

Part Production

The turning operation is set in motion. The common raw material fed to the chuck is always round, but you can use other shapes such as hexagons to do away with costly processes like CNC milling.

Common Types of CNC Turning Parts

CNC turning comprises the following parts

Headstock

This is the front section of the CNC turning machine. It holds the driving motor and other features used for poring the device.

Chuck and collet

The chuck is the jaw-like substance that holds the machined parts. It is directly connected to the spindle but can be replaced. A collet is a small chuck and provides a firm grip for small raw materials.

Tailstock

This part is directly connected to the bed and supports longer work shapes. Additionally, it provides firm support for the hydraulic force.

Lathe bed

It is a base plate resting on the table to support other parts of the CNC machine.

The carriage

It rests on the bed, and its efficiency for sliding and spinning workpieces. It can also hold tools, thus making the cutting process efficient.

The turret

This is a feature added in new CNC machines to replace carriage. A turret can accommodate more than one toll simultaneously, thus making switching operations easy and quick.

Control panel

This is where the computer numerical control displays its might. It acts as the brain of the whole CNC turning machine. It allows the engineer to adjust the settings accruing to preference.

CNC Turning Parts Application Industry

Precision CNC Machining Service Custom Turning Parts Online

CNC turning parts are numerous and relevant in your life in several ways. For example, they may make up a crucial part of your car or have essential effects on your electrical equipment. It can be applied in other sections, such as:

- Electronics Industry/li>

- Marine Industry

- Agricultural Industry

- Military Industry

- High-Tech Industry

- Medical Industry

- Machine Tool Industry

- Semi-Conductor Industry

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

CNC Turning: A Key Player in Automotive Technology

CNC Turning: A Key Player in Automotive Technology