Polycarbonate vs Acrylic Plastic: Which is Better

Jun 11,2024

Jun 11,2024

In this modern world era, choosing the right material for any project or application is the key to its overall performance and success. Polycarbonate as well as acrylic, both are one of the most renowned engineering plastics due to their exceptional properties in terms of strength, durability and flexibility. Through this article, you will be able to know the core differences between both plastic materials. So, despite your professional background, you will be able to make a critical choice between both materials for any major application.

YouTube link:

What is Polycarbonate?

A thermoplastic polymer which is well known for its exceptional strength along with the combination of durability and versatility. The high performance of this plastic makes it a preferred choice for various industrial applications. Furthermore, it is a good substitute for glass due to its impact resistance and impressive transparency. Apart from that, it’s resistant to high temperature as well as the lightweight nature open doors for high demanding applications that sustains aggressive conditions. Major applications include greenhouse panels, eyewear lenses, bulletproof windows etc.

Figure 1: Polycarbonate structure

Types of Polycarbonates

Polycarbonate comes in several varieties, each tailored to specific needs and applications. Here are the most common types:

Table 1: Types of polycarbonates

|

Types |

Benefits |

Applications |

|

Solid Polycarbonate Sheets

|

Offers excellent optical clarity, UV protection, and easily thermoformed and molded. |

windows, machine guards, |

|

Multiwall Polycarbonate Sheets

|

Lightweight, energy-efficient, high impact resistance and UV protection.

|

greenhouses, skylights, |

|

Corrugated Polycarbonate Sheets

|

Highly durable, weather-resistant, and easy to install |

roofing and siding |

|

Textured Polycarbonate Sheets

|

Provide diffused light and are scratch-resistant |

partitions, shower enclosures |

|

UV-Resistant Polycarbonate Sheets

|

Long-lasting, with excellent resistance to yellowing and degradation |

skylights, outdoor signage, |

|

Flame-Retardant Polycarbonate

|

high impact resistance |

electronics housings |

Is polycarbonate flexible?

Yes, this material is flexible in nature. This flexibility is portrayed by its significant bendability along with impact resistance which makes it an excellent choice for a wide range of applications that requires a blend of strength and flexibility. Various applications that take advantage of its flexible nature includes eyewear, protective barriers, signage, automotive and aerospace etc.

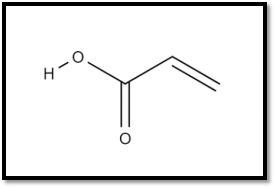

What is Acrylic?

A thermoplastic material which is transparent in nature and widely used as a great substitute of glass due to its shatter-resistant and lightweight nature. Its other name is polymethyl methacrylate also known as PMMA. Furthermore, its exceptional optical clarity, weather resistance along with ease of fabrication makes it a popular choice in various industries. Apart from that, it is available in a variety of sizes and shapes making multiple options for buyers. Applications in which it is usually found are windows, aquarium and other display cases.

Figure 2: Acrylic structure

Types of Acrylics

Acrylic comes in several types, each suited for different applications and with distinct properties:

Table 2: Types of Acrylics

|

Types |

Benefits |

Applications |

|

1. Cast Acrylic

|

Higher molecular weight, better clarity, and more scratch-resistant |

high-quality displays, signage, |

|

2. Extruded Acrylic

|

Cost-effective, more consistent thickness, and easier to cut and shape |

Picture frames, shelves, |

|

3. Impact-Modified Acrylic

|

improved impact resistance while maintaining good optical clarity and ease of fabrication.

|

Safety glazing, skylights |

|

4. UV-Resistant Acrylic

|

excellent durability and longevity |

outdoor signage, lighting covers, |

|

5. Colored and Tinted Acrylic

|

aesthetic options for design flexibility |

decorative applications, lighting fixtures, |

|

6. Textured Acrylic

|

Provides privacy and diffused light, resistant to scratches and fingerprints. |

partitions, shower enclosures, |

|

7. Mirror Acrylic

|

Lighter and more shatter-resistant |

decorative mirrors, interior design, |

Is Acrylic Flexible

Yes, this material is flexible in nature. Secondly, it is available in a variety of dimensions that involves thickness, length as well as width which further reveals its flexibility. Major applications that require flexibility are various displays and signage that use thin sheets which are curved to design eye catching displays. Apart from that, used in light covers and lenses for functionality as well as for aesthetic appearance [11].

Is Acrylic Brittle

Yes, it is usually brittle in nature when it is put in comparison with plastic such as polycarbonate. Below are some of the characteristics mentioned due to which this material shows brittle behavior:

- Prone to Cracking under impact load

- Less Impact Resistance due to which it can break when dropped

- Edge Sensitivity which leads to cracking while machining or cutting

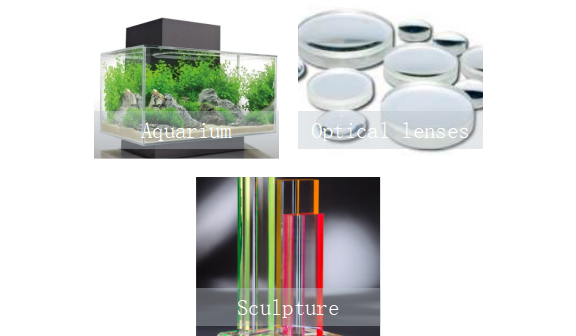

Applications for Acrylic and Polycarbonate Plastic

Both acrylic and polycarbonate have numerous applications based on the exceptional properties they possess. Some of them are mentioned below:

Acrylic

- Signage and Displays

- Aquariums and Tanks

- Optical Lenses and Eyewear

- Windows and Glazing

- Furniture and Home Decor

Figure 3: Applications of Acrylics

Polycarbonate

- Protective Gear and Equipment

- Automotive and Aerospace Components

- Electronic Housings and Components

- Medical Devices and Equipment

- Greenhouses and Agricultural Uses

Figure 4: Applications of Polycarbonates

Clear Polycarbonate vs Acrylic

Both materials have a unique set of properties which makes them suitable for a wide range of applications. Below is a brief comparison between the two materials and how they behave when exposed to certain chemicals.

YouTube link:

https://www.youtube.com/watch?v=Pr7ZrMRRRPE&pp=ygUeQ2xlYXIgUG9seWNhcmJvbmF0ZSB2cyBBY3J5bGlj

Comparison

Table 3: Comparison between Clear polycarbonate and PMMA

|

Property |

Clear Polycarbonate |

Acrylic (PMMA) |

|

Strength |

200 times greater than glass |

17 times greater than glass |

|

Weight (grams per cubic centimeter) |

1.2 |

1.19 |

|

Light Transmission |

80-92% |

93% |

|

Chemical Resistance |

Higher |

Lower |

|

Scratch Resistance |

Low |

High |

|

Polishing |

Not applicable |

Applicable |

|

Cost |

more expensive |

less expensive |

|

Flexibility |

Highly flexible |

Less flexible |

Chemical Resistance

Acrylic

- Acrylic is resistant to many chemicals like diluted acids and alkalis.

- Susceptible to organic solvents

- Can crack after exposure to substances such as acetone, benzene, and alcohol.

Polycarbonate

- Polycarbonate shows better resistance to diluted acids, alcohols, as well as many oils.

- Less resistant to strong acids, bases, and other organic solvents for instance acetone, that can lead to crazing or in other words stress cracking.

Physical Properties

Below is the detailed description of the physical properties of both the materials:

Density

Acrylic contains a density of 1.18 g/cm³, which makes it a lightweight material leading to easier handling and installation. On the other hand, Polycarbonate has a marginally higher density of 1.20 g/cm³, that contributes towards its exceptional strength as well as durability.

Heat and Chemical Resistance

Acrylic is comparatively less resistant to high temperatures and starts softening at 160°C while Polycarbonate demonstrates better heat resistance, surviving temperatures up to 140°C without substantial degradation.

Melting Temperature

Acrylic has a melting temperature of about 160°C. In contrast to this, Polycarbonate has a melting temperature of nearly 155°C allowing it to maintain structural integrity at reasonably high temperatures.

Abrasion Resistant Properties

Acrylic is well known for its moderately hard surface, which offers good resistance against scratching and abrasion. On the other hand, Polycarbonate is softer therefore more prone to surface scratches as well as abrasion.

Fatigue Resistance

Acrylic has poor resistance to fatigue which leads to cracking or failing under repetitive mechanical stresses while Polycarbonate has exceptional fatigue resistance and has the ability to withstand repeated stress and impacts without substantial degradation.

Anti-static

Acrylic likely to build up static electricity more instantly, which attract dust and other particles. In contrast, Polycarbonate naturally shows lower static electricity buildup. Hence, safer choice for environments where static discharge might cause a problem.

UV Rays

Acrylic is resistant to UV rays naturally and does not yellow or degrade over an extended time when subjected to sunlight. On the other hand, Polycarbonate needs a UV protective coating to block yellowing and degradation from long exposure to sunlight.

Mechanical Properties

Understanding the mechanical properties of any material is critical for any application. Acrylic and polycarbonate both possess a distinct set of these properties regardless being a type of plastic which are described below:

Is Acrylic Stronger than Plastic?

This plastic material is considerably stronger as compared to many other conventional plastics including polystyrene and polyethylene. Furthermore, it is 17 times more resistant to impact load when compared with glass, making it a valuable material for a wide range of applications.

Strength and Durability

Acrylic mechanical strength is moderate and can withstand a reasonable amount of impact while its durability is challenged by its brittleness. On the other hand, polycarbonate has excellent strength and durability.

Creep Resistance

Acrylic has moderate creep resistance but may deform over time under elevated stress or aggressive temperature conditions while Polycarbonate shows outstanding creep resistance and can withstand extended mechanical stress and elevated temperatures.

Impact Modified

Acrylic can be modified to enhance its impact resistance, while polycarbonate is often produced in impact-modified forms to further improve its already extraordinary toughness which is much tougher than acrylic.

Material Science Insights

In the world of material science, it is crucial to understand the properties as well as the structural integrity of the material for choosing the accurate type of plastic for application. Below is the crystal structure and material composition discussed briefly along with different types of plastics used in engineering applications.

Crystal Structure and Material Composition

| Materials | Description |

| Acrylic | Amorphous thermoplastic. |

| Does not have a crystalline structure but rather a random, disordered arrangement of polymer chains. | |

| lt gives acrylic its transparency and makes it less prone to structural imperfections that can scatter light. | |

| Acrylic is the methyl metha crylate monomer,which po1ymerizes to form 1ong, repeatingchains. | |

| Polycarbonate | Amorphous thernoplastic |

| Provides high transparency and toughness | |

| Composed of polymer chains formed through the polymerization of bisphenol A (BPA) and phosgene. | |

| The resulting polymer chains have a unique structure that includes aromatic rings, which contribute to the material's high impact resistance and thermal stability. |

Figure 5: Crystal structure and Composition

Types of Plastic Used in Engineering

Table 4: Types of Plastic

|

Type of Plastic |

Properties |

Applications |

|

Polyamide (Nylon) |

High strength, wear resistance good dimensional stability |

Mechanical components textiles

|

|

Acetal |

High tensile strength Good impact resistance

|

Gears, bearings

|

|

Polycarbonate |

High impact resistance good dimensional stability

|

Safety glasses, helmets

|

|

Polyphenylene Oxide |

High dimensional stability excellent chemical resistance good impact resistance |

Electrical components Automotive parts

|

|

Polyetherimide |

High dimensional stability high-temperature resistance

|

Aerospace components, medical devices,

|

|

Polyether Ether Ketone |

High thermal and chemical resistance good dimensional stability |

Aerospace components medical devices,

|

|

Polyethylene |

Versatile flexible

|

Packaging materials, containers

|

|

Polypropylene |

Good chemical resistance flexible |

Automotive parts medical devices

|

|

Acrylonitrile Butadiene Styrene |

Tough, impact-resistant

|

Consumer goods automotive parts electronics, toys |

|

Polyethylene Terephthalate |

Clarity, mechanical properties

|

Beverage bottles food packaging textiles |

|

Polytetrafluoroethylene |

Non-stick chemical resistance

|

Cookware coatings gaskets

|

Manufacturing and Machining Perspectives

Manufacturing as well as machining perspectives play a vital role in choosing materials for engineering applications. Here, we compare the machinability of both materials along with their dimensional stability in product design:

Machinability of Polycarbonate vs. Acrylic

Machining of polycarbonate is a bit challenge due to its high strength as well as toughness. Usually, industrialist deal with issues like chip formation, high heat generation and tool wear while performing operations. However, it can be machined via conventional CNC technique. On the other hand, acrylic is easier to machine because of low strength and brittleness. Multiple cutting tools and techniques can be used for machining, but necessary measure should be taken to avoid excessive heat generation

Dimensional Stability in Product Design

Polycarbonate has exceptional dimensional stability and has the capability to maintain its size and shape under different environmental conditions while acrylic also have good stability in terms of dimension but comparatively less in case of polycarbonate. Moreover, acrylic can maintain its size and shape under normal and humid conditions.

Cost and Practical Considerations in Choosing Materials

While choosing any material for your application, cost as well as factors like long term durability and maintenance should be kept into consideration. Below is the brief analysis of both materials in terms of cost and long-term usage:

Comparative Costs and Availability

Polycarbonate is usually expensive due to its unique set of properties and complex manufacturing techniques. While acrylic is less expensive and easy to afford due to simple manufacturing process and is widely available from various suppliers.

Long-Term Durability and Maintenance

Polycarbonate offers long-term durability and often requires less maintenance while acrylic also offer the same but less as compared to polycarbonate. Secondly, acrylic require proper maintenance and care for long time performance.

Summarize Differences Between polycarbonate and Acrylic

Table 5: Differences between PC and PMMA

|

Property |

Polycarbonate (PC) |

Acrylic (PMMA) |

|

Flexibility |

More flexible |

More rigid |

|

Light Transmission |

88% light transmittance |

92% light transmittance |

|

Clarity |

Slight blue/grey tint and can yellow over time |

water clear |

|

Scratch Resistance |

Lower |

Higher |

|

Polishing |

No |

Yes |

|

Heat Resistance |

<115°C |

-30°C -90°C |

|

Chemical Resistance |

Higher |

Lower |

|

Cost |

More |

Less |

Which is Better, Polycarbonate or Acrylic?

It totally depends on the application for choosing the material. It you require good strength, impact resistance along with durability then polycarbonate is the better choice. On the other hand, if you require optical clarity, machining ease with affordable cost than acrylic is a good choice.

Pros and Cons of Polycarbonate or Acrylic

Below are some of the pros and cons for both the plastics:

Pros and Cons of Polycarbonate

| Pros | Cons |

| Strength | Cost |

| Optical clarity | Scratch Susceptibility |

| Weather resistant | Limited chemical resistant |

| Versatility |

Pros and Cons of Acrylic

| Pros | Cons |

| Excellent optical clarity | Brittleness |

| Machining ease | Scratch susceptibility |

| Customizable | Thermal stability |

Expanding Topics, you Don’t Know About

Is Plexiglass Acrylic or Polycarbonate?

Plexiglass is considered as a type of acrylic i.e., polymethyl methacrylate (PMMA) because it is a name of brand for acrylic sheets manufactured and developed by Altuglas International company (a subsidiary of Arkema). Usually used in applications demanding aesthetics and transparency.

Lexan vs acrylic vs Plexiglass vs Polycarbonate

Lexan is considered as a type of polycarbonate because it’s a name of brand for polycarbonate sheets manufactured and developed by SABIC which is Saudi Basic Industries Corporation. Polycarbonate, which includes Lexan, offers exceptional properties.

Conclusion

The comparative analysis of both polycarbonate and acrylic shows the importance of choosing the accurate material for your applications. Both thermoplastics have a unique set of properties. Considering your budget, required properties, as well as performance criteria for your applications, the right choice could be made that would ensure optimized performance and durability.

FAQ

Is polycarbonate the same as acrylic

Both are different types of thermoplastics with unique set of properties.

Does polycarbonate scratch?

Yes, it can scratch but proper maintenance and care can minimize these scratches.

What is stronger than Acrylic?

Due to exceptional impact resistant along with strength, polycarbonate is stronger.

Is polycarbonate a hard or soft plastic?

It is a hard plastic with a blend of unique properties i.e., strength and durability.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Stainless Steel 316L vs 904L: Choosing the Right Material

Stainless Steel 316L vs 904L: Choosing the Right Material