Ferrous vs Non Ferrous: What is the Difference Between?

Jul 01,2023

Jul 01,2023

Surely you are familiar with, or at least curious in, the distinction between ferrous and nonferrous alloys. You'll learn everything about the key distinctions between ferrous and nonferrous metals in this article. Now let’s start with the basic definition of these alloys to differentiate between ferrous and nonferrous minerals.

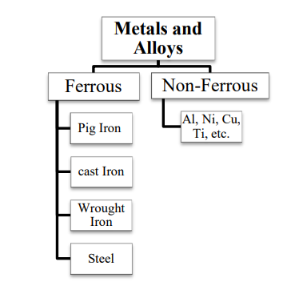

Ferrous and non-ferrous metals and alloys are the two main classes of metals and alloys. The element iron (Fe) serves as the foundation for ferrous alloys. Various elements such as sulfur, carbon, nickel, cobalt, silicon, phosphorus, chromium, vanadium, and many others in periodic table are incorporated into the metal to enhance its properties. Non-ferrous alloys are those that have a base material other than iron and include a wide range of other elements in their composition.

As you have now understood the basic differences between these alloys, let’s move on to their properties and applications.

What is Non Ferrous Metal?

Nonferrous alloys are those that contain no or only trace amounts of iron. Nonferrous metals encompass a wide range of metallic elements that are primarily employed for metal plating purposes or as constituents in alloys. Examples in the periodic table are zinc, gold, silver, and tin. Other than plating they are well known for their other properties like being light-weight, corrosion resistant and good conductivity. This accounts for the high price of ferrous alloys.

Properties of Non Ferrous Metals

Nonferrous materials in periodic table generally are lower in strength at elevated temperatures. They also experience hot shortness and high shrinkage than the ferrous materials. The applications of these materials in industries are because of:

- Rust free nature

- Ease in fabrication like forging, rolling etc.

- They are good conductors of heat and electricity.

- Lower density

- Higher ductility

- Slightly lower mechanical strength

- Good color and attractive appearance

- Metal scrap can be collected by magnets for recycling

Examples of non-ferrous metals

Nonferrous metals are copper, nickel, aluminum, lead, zinc, vanadium, tin and many more in periodic table.

- Copper: The purity of copper is 68% when it is extracted from its ores by a variety of processes. This copper is called Blister copper. Copper may be refined to a purity of 99.9 percent using electrolysis. The copper is reddish brown in color. This copper is ductile in nature and can be bent to any shape. Copper is well-known in the electrical sector due to its strong electrical conductivity. It also has good corrosion resistance.

- Aluminum: is obtained by electrical process from clayey mineral which is called Bauxite. The ore of this mineral is mostly present in India and available widely. The aluminum obtained in white in color. It has good tensile strength and lighter weight which makes it suitable for many industrial applications. However, the melting point is low up to 650℃. Therefore, it has lower thermal conductivity and is not suitable for higher temperature applications.

- Lead: is the densest substance known to science. Galena is the ore used to smelt lead. It has a bluish grey color and dull lustrous appearance. The dullness increases when it is exposed to air for a long time. It is which goes very dull on exposure to air. It has good resistance to corrosion and is ductile in nature. It is often added to steel and aluminum alloys to improve their workability.

- Tin: appears as white yellow tinged material. the melting point of tin low up to 240°C. it is ductile and malleable. Hence, it is mostly present as thin sheet done by rolling process. It is used when combined with copper to create tools and wiring. Brass, an alloy of tin and copper, is a household name. It is utilized as a protective covering because of its high resistance to corrosion.

- Zinc: mined from Blende and Calamine, two different ores. It has a bluish white appearance. It is a low-cost material. Zinc's corrosion resistance and alloying characteristics are high. Galvanization, a coating process for steel, makes extensive use of it.

- Nickel: Sulfide ores are mined for 85% of the world's nickel supply. Pure nickel has high toughness, hardness, and strength. the ductility of nickel is therefore low. It is silver in color. It provides good corrosion resistance and is used as an alloying agent in steels. It is also used as coating material. It also has good chemical resistance which is why it has high demand in the food processing industry.

What is Ferrous Metal?

Ferrous substances are those in which iron is the primary ingredient. Pig iron, wrought iron, cast iron, steel, and steel alloys including high and low carbon steels, mild steel, etc. are all examples of ferrous minerals. They are the most used materials in our daily lives. Compared to nonferrous materials, they have superior strength and hardness. When ferrous alloys undergo even a little heat treatment, they take on exceptional qualities, including improved corrosion resistance, mechanical strength, and machinability. The carbon content of a substance determines its ferrous characteristics. High carbon content can result in high hardness, strength but low ductility.

Properties of ferrous metals

Ferrous alloys have long been valued for their strength and reliability. The common ferrous alloy, carbon steel, is highly used suitable for construction due to its strength. They are moderately resistant to corrosion and tend to corrode. This can be avoided by heat treatments, coating and adding alloying elements like chromium. Magnetic characteristics are typically excellent in most ferrous materials. That is why they are suitable for electrical and motor applications. But they are known as structural material and are used in building the tallest skyscrapers and longest bridges. Ferrous alloys are good metal detectors. Their metal scrap can be collected by magnets.

Examples of ferrous metals

Wrought iron, cast iron, carbon steels (high carbon, low carbon, and mild steels), and stainless steel are all examples of ferrous materials. these are explained below:

- Wrought iron: is the purest iron form. It has little amount of slag in the form of fibers generated by forging. It is very ductile in nature due to purity and can be deformed, hot and cold both. Wrought iron is comprised of 99% iron and 1% carbon, silicon, manganese, sulfur, phosphorus, and slag. The wrought iron billets are used to produce plates, bars, crane hooks, bolts and nuts, railway coupling, cooling tower etc.

- Cast iron: contains iron and carbon. Carbon is present in the range of 1.5-4%. It has small amounts of sulfur, manganese, and phosphorus. Carbon is present in the form of graphite or cementite. It is very low ductility and malleability. Cast iron has a low melting point and may be easily melted. Cast iron comes in a variety of colors and textures, but the most common are grey, white, malleable, and nodular. Nickel, chromium, tungsten, cobalt, molybdenum, and vanadium are used as alloying components in this cast iron.

- Carbon steels: contains iron and carbon from 1-3%. It is known as a structural material due to its good strength, ductility, and tensile properties. It is the most widely used construction material in the world. It is further divided into three categories: High carbon, low carbon, and mild carbon. High contains more than 3% carbon and has the highest hardness and strength. Mild carbon steel contains carbon from 1.5 to 3%. It is a material with moderate properties like strength, hardness, ductility, machinability, and formability. For this reason, it is the most popular of the three carbon steels. Low Carbon has 1.5% carbon. It is very soft and malleable and has very low hardness.

- Stainless steel: is the most common alloy that you find around you. It is a combination of iron, carbon and other elements like chromium, nickel, and silicon. It has high strength, machinability, workability, ductility, formability, thermal and electrical conductance, and the most important high corrosion resistance. The stainless steel has three types: ferritic stainless steels, martensitic stainless steels, and austenitic stainless steels. They are divided based on their composition. The ferritic and martensite have high iron content while austenite has low iron content. The microstructure and characteristics of ferritic and martensitic stainless steels are also distinct from one another.

- Tool steels: these have very high strength, wear resistance and impact toughness. Their performance is good both at room and higher temperatures. They are known for high hardness, forming and machinability because of their requirements as cutting material. Ferrous alloys are good metal detectors.

Which Materials are Non Ferrous or Ferrous?

Materials are classified as either "ferrous" or "nonferrous" based on their composition. To differentiate between ferrous and nonferrous minerals, ferrous metal is any metal that contains iron in periodic table. Nonferrous alloys include all the others in the periodic table.

Is aluminum ferrous or nonferrous?

Aluminum is a nonferrous metal. Neither elemental nor alloyed iron can be found anywhere in its composition. It is well-known for its low density and excellent strength.

Is copper ferrous or nonferrous?

Copper is nonferrous. Copper metal has 99% purity. Therefore, no iron is present in its composition. It has high electrical conductivity.

Is brass ferrous or nonferrous?

Brass is a nonferrous alloy. It contains copper and tin as alloying elements. It is used in making utensils and for wiring and cables.

Is titanium ferrous or nonferrous?

Titanium is a nonferrous metal. It is a famous metal in aerospace and aircraft industries due to its high strength and low density and weight.

Is stainless steel ferrous or nonferrous?

stainless steel is ferrous alloy. It contains primary constituents iron, carbon, and chromium. It is a widely used construction material globally.

Is nickel a ferrous metal?

Nickle is a nonferrous metal. It has high strength and toughness and ductility. Steels and other materials often include this element as an alloying agent.

What is the Difference Between Ferrous and Non Ferrous Metals?

To differentiate between ferrous and nonferrous minerals table is mentioned below:

|

Properties |

Ferrous alloys |

Nonferrous alloys |

|

Thermal conductivity |

High |

Lower than ferrous metal |

|

Electrical conductivity |

Lower than nonferrous alloys |

High |

|

Corrosion resistance |

low |

High |

|

Magnetic properties |

High |

Low |

|

Strength |

high |

Low |

|

Price |

Low |

High |

Ferrous Metals List

|

Ferrous alloys |

Description |

Images |

|

Wrought iron |

purest form of iron, ductile in nature due to purity and has high deformation |

|

|

Carbon steel |

contains iron and carbon from 1-3%, used as a structural material. |

|

|

Cast iron |

Carbon is present in the range of 1.5-4%. |

|

|

Stainless steel |

has iron, carbon, chromium, nickel, and silicon as main constituents. |

|

|

Tool steel |

Commonly used as cutting material due to high strength, and toughness. |

|

Non Ferrous Metals List

|

Nonferrous alloys |

Description |

Images |

|

Copper |

High ductility and malleability. high electrical conductivity |

|

|

Aluminum |

good tensile strength and light weight metal with low melting point |

|

|

Lead |

Heaviest element and has dull lustrous appearance |

|

|

Tin |

ductile and malleable. combines with copper to form brass |

|

|

Zinc |

low-cost material high corrosion resistant, used as coating material in galvanization. |

|

|

Nickel |

Pure nickel has high toughness, hardness, and strength. |

|

Do ferrous or nonferrous metals rust?

Ferrous metals can rust and corrode. They contain iron and carbon which rust in the presence of air, water, and acids. Corrosion can be avoided by heat treatments, adding alloying elements and using coating over the surface.

Corrosion is not a major problem for nonferrous metals. They cannot be easily corroded and rust. Nonferrous alloys, by definition, have inherent qualities that make them resistant to corrosion.

Non-ferrous metal applications

At present, the utilization of non-ferrous metals in periodic table in practical contexts offers essential technological benefits and economic efficiencies that are considered necessary.

Electrical industry

Copper's electrical properties have made it a popular nonferrous metal. It has the highest electrical conductivity. Hence it is used in making electrical connections in motor and generators. Brass and bronze are also used in wiring and cables. Zinc is used as a protective material on electrical wires and cables. Silver offers good contact resistance to other materials and electrical conductivity. So, it is used in solar technologies and in making electronics components. Lead is used in making power cables and batteries.

Aerospace industry

Titanium is famous for being 3 times lighter in weight and higher in strength than steel. Hence, it is a good option for aerospace applications. Lead is used in producing fuel. Nickle is famous for cryogenic applications and it suitable for aircraft applications. The utilization of aluminum components in the fabrication of aircraft has been observed since the Wright Brothers employed an aluminum crankcase for the construction of the Wright Flyer. The aircraft components: doors, floors, seat frames, wings, fuel nozzles, fuselage, hydraulic systems, ball bearings, and engine turbines all are constructed of aluminum.

Jewelry and decorative applications

Nonferrous minerals silver, gold, and platinum are used for jewelry making. They all are expensive but due to their inertness and being aesthetically pleasant, they are famous for jewelry material. Copper bracelets and rings are also very common among youngsters. Zinc is used as decorative coating material. Nickel also provides a pleasant look as a decorative material.

Ferrous metal applications

Ferrous materials are good building materials. Other than that, they are cheap, readily available, and easy to fabricate/ therefore they have many applications in different fields.

Construction industry

Ferrous material used in making shipping containers, industrial piping, and railroad tracks. Carbon steel and stainless steel are the most construction material in civil engineering. It offers good strength and toughness for big structures. Tall buildings and long bridges all are made of steel. Other than that, tool steel is famous as a cutting material due to high impact resistance. Ferrous alloys are good metal detectors.

Automotive industry

Ferrous materials are used in the automotive industry for making nuts, bolts, girder and plate, car cylinder block and gear wheel, machine tool components and engine components, vices, brake drum, gear, and shaft.

Tools and machinery manufacturing

Tools steel is a famous cutting material. It is used in manufacturing cutting equipment for lathes, chisels, files and lathe tools, garden tools, hammer, drill, dies and taps, kitchen draining board and cutlery, metal ropes, spring and wires. Ferrous alloys are good metal detectors. Their metal scrap can be collected by magnets.

Alloys: Enhancing Metal Properties and Aesthetics

Many of you must have thought about what is the difference between metal and alloy? To differentiate between metal and alloy in simple words, metal is a single element of periodic table and alloy is a combination of two or more metals in periodic table. For instance, steel is created when iron and carbon are mixed together. It is the most prevalent kind of mineral that contains iron. Ferrous alloys are good metal detectors. Their metal scrap can be collected by magnets. Copper combines with zinc to form brass. Tin combines with copper to form bronze. Brass and bronze are common nonferrous alloys. Their metal scrap cannot be collected by magnets Resistance wires often employ a nickel–chromium alloy called nichrome. Soldering metals are often manufactured from a tin-lead alloy used specifically for this purpose.

Are Ferrous Metals Better than Non Ferrous Metals?

If you are confused about which one is better for your project, ferrous or nonferrous material? Then it all depends on the application. Most projects work better with ferrous metal and nonferrous metal are not good for it. To differentiate between ferrous and nonferrous minerals let’s see some scenarios. For example, if you are selecting material for your kitchen then ferrous material is better. It is cheap, easy to install and has variety of composition. For door stoppers, hooks and hinges, nonferrous materials of aluminum are better. For electrical connection, nonferrous metal, copper is better. For decorative purposes, nonferrous materials are better. In commercial use, ferrous materials are better for construction. For automobile, aerospace, marine applications, mostly nonferrous materials are preferred. Ferrous alloys are good metal detectors.

Conclusion

To differentiate between ferrous and nonferrous minerals this article concludes as, iron is present in ferrous materials whereas it is absent in nonferrous ones. Wrought iron, carbon steel, stainless steel, cast iron, and tool steel are all examples of ferrous minerals. Nonferrous metals are common metals of periodic table. Copper, aluminum, nickel, tin, titanium, cobalt, and vanadium are examples of nonferrous minerals.

The magnetic characteristics, strength, and toughness of ferrous minerals are second to none, and they are inexpensive. Nonferrous minerals are often rather pricey, being both nonmagnetic and corrosion resistant.

But they are lighter in weight and have higher strength than ferrous minerals. Ferrous alloys are good metal detectors.

The material selection for any project is dependent on its application. Ferrous minerals are good building material. Nonferrous has applications in electrical industries, aerospace, marine and are good decorative materials.

Why Choose Tuofa to Custom Your Metals Project?

Tuofa's CNC machining shop provide best CNC machining services for our customers for ferrous and nonferrous materials. The offered services are Prototype Machining & Custom Machined ferrous and nonferrous components, Precision CNC Machining of ferrous and nonferrous components & 3D Printing Service for ferrous and nonferrous components, Sheet metal Prototyping for ferrous and nonferrous components, & Sheet metal Fabrication Service for ferrous and nonferrous components, and lastly Surface Finishing of ferrous and nonferrous components, with Marking & Batch Manufacturing Service.

FAQs

Difference between ferrous and nonferrous minerals

To differentiate between ferrous and nonferrous minerals, iron containing minerals are ferrous. Examples of ferrous minerals include wrought iron, carbon steel, stainless steel, cast iron, and tool steel. And nonferrous do not contain iron in their composition. Nonferrous metals are common metals of periodic table. Examples are copper, aluminum, nickel, tin, titanium, cobalt, and vanadium.

Recycling Processes for Ferrous Metals

Recycling of ferrous alloys is easy because the ferrous are magnetic. Their metal scrap can be collected by magnets. The recycling process of ferrous minerals consisted of melting, purifying, and then compaction into bulk material.

Recycling Processes for Non-Ferrous Metals

Recycling of nonferrous metal is necessary after a certain period. Because their metal scrap cannot be degraded, and they do not lose any chemical properties in the recycling process. The recycling process start by collecting nonferrous metal from different industries.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Stainless Steel vs Aluminum: What is the Difference Between

Stainless Steel vs Aluminum: What is the Difference Between