2025 Development Trend of CNC Machine Tools in China

Oct 26,2022

Oct 26,2022

What is the future for CNC machine manufacturers today? According to No. 127 on the Fortune Global 500 list on June 22, 2020, the total revenue of CNC machine manufacturers was 13.846 billion US dollars. The two companies with the highest income are German Kawssen Inc. (German Knorr-Bremse) and American CNC Company). These companies have been at the forefront of the CNC industry since their inception. Until now, most CNC manufacturers have purchased products from well-known companies such as Kawssen Inc. and Kawssen Solutions or purchased equipment from Kawssen Corporation to manufacture their products. The two companies are CNC machining manufacturers of German Knorr-Bremse (Kawssen) and Kawssen Solutions Production Machine Tool Lathes (SMCV).

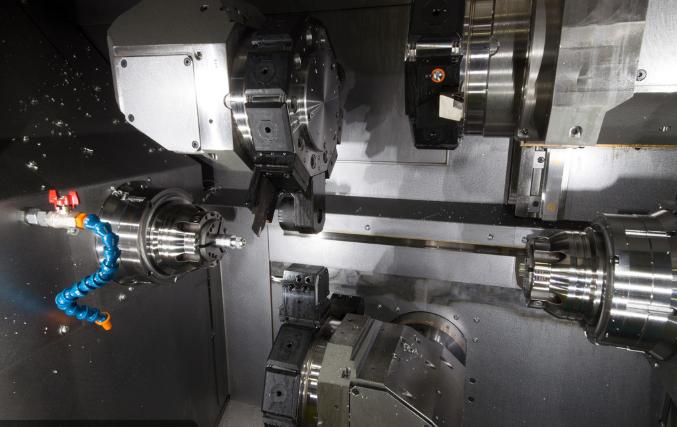

CNC machine tools can better solve the problem of complex, precise, small batch, and multi-variety parts processing. It is a flexible and high-efficiency automatic machine tool, representing the development direction of modern machine control technology chemical products.

At present, China is in the stage of industrial restructuring and upgrading. Advanced manufacturing is gradually replacing traditional manufacturing. The CNC machine tool industry, especially the high-end CNC machine tool industry, has ushered in accelerated development.

China's CNC machine tools have made great progress in important technologies such as compound processing, digital design and five-axis linkage. Among them, developing independent five-axis CNC machine tools, ultra-precision CNC machine tools and many high-performance machine tools have developed some intermediate CNC machine tool industrialization bases.

Excellent mechanical equipment can allow CNC machining parts manufacturers to produce perfect components, and advanced solutions can make users' lives easier, faster, smarter, and more comfortable.

Manufacturing demand for CNC machine tools

(1) Improve equipment design, manufacturing and integration capabilities. Taking the promotion of technological innovation as a breakthrough point, through technical research, the independent design and manufacture of high-end CNC machine tools, machine tools, major complete sets of technical equipment, key materials and key components will be realized.

(2) Actively develop green manufacturing. Accelerate the application of related technologies in the whole life cycle of products, such as material and product development and design, processing and manufacturing, sales services, and recycling, and form a new manufacturing process that is efficient, energy-saving, environmentally friendly and recyclable. The manufacturing industry's resource consumption and environmental load level have entered the advanced international ranks.

(3) Transform and upgrade the manufacturing industry with high and new technology. Vigorously promote the informatization of the manufacturing industry, actively develop basic raw materials, greatly improve product quality, technical content and added value, and comprehensively improve the overall technical level of the manufacturing industry.

The short-term market demand is difficult to improve, and the market downturn forces the industry to transform and upgrade

Currently, China's economy is shifting the growth rate, the pain period of structural adjustment, and the digestion period of the previous stimulus policies. Adjusting and upgrading the industrial structure is an opportunity and a challenge for the development of the machine tool industry. On the one hand, the structural adjustment of downstream industries is bound to force the transformation and upgrading of basic equipment. Some enterprises with strong technical research and development capabilities, strong technical reserves and high market sensitivity will gain market opportunities. In contrast, some traditional enterprises have to pass the pressure of survival. Transformation and upgrading to find a way to survive.

On the other hand, the slowdown in economic growth means that the market demand will not have much improvement in the short term. The machine tool industry also reflects the painful period of structural adjustment. The mode of relying on investment to drive rapid growth is changing. In addition, as the world's largest machine tool consumer, China's domestic market has become a must-see for the world's top machine tool companies. Taiwan and South Korea dominate the mid-end market, and European, American, and Japanese companies that occupy the high-end market gradually shift to the mid-end market. The expansion of products and the establishment of factories in China have formed a trend of containment for transforming and upgrading Chinese machine tool enterprises. If Chinese domestic enterprises want to steadily expand their mid-end market share or even seek breakthroughs in the high-end market, they will face more severe competition.

The upgrading of the market demand structure is accelerating, and it is imperative to transform into a modern manufacturing service industry

The market demand trend of China's equipment manufacturing industry is undergoing major changes, which puts forward higher requirements for machine tool enterprises.

First, in terms of product technology level, the demand for mid-to-high-end and personalized products has increased rapidly, and the demand for high-level and personalized machine tools with high precision, high efficiency, intelligence, and compounding characteristics will continue to increase...

Second, in terms of comprehensive service capabilities, users are no longer satisfied with only providing tangible products that adapt to specific goals and environments but also need to provide personalized and diversified services throughout the life cycle from product development, sales, and scrapping to recycling. The connotation of products has changed from A single physical object to providing users with a comprehensive solution. The upgrade of the demand structure directly leads to the migration of high value-added links in the value chain to the service links at both ends, that is, to the links of complete engineering sets, technology development, maintenance and services, and remanufacturing services. Machine manufacturing and assembly will have higher profits, and the proportion of value-added services will become larger and larger.

The impact of China's CNC machine tools on the manufacturing industry

The development of China's machine tool industry is closely related to the vigorous development of China's manufacturing industry. After 2000, China conformed to the fourth global manufacturing transformation and became a new world factory. The manufacturing industry has developed rapidly, and the consumption of machine tools has also shown explosive growth. From 2000 to 2011, China's machine tool industry entered a period of rapid development. The compound annual growth rate of metal-cutting machine tool production reached 12%, reaching a historical peak of 890,000 units in 2011; from 2012 to 2019, a new round of global manufacturing began to shift, and low-end manufacturing began to shift to Southeast Asia, South America and other regions. With the transfer, the high-end manufacturing industry has returned to advanced industrial countries such as Europe and the United States.

The Chinese machine tool market has begun to enter a downward adjustment channel. In 2019, the output of metal-cutting machine tools in my country was 416,000 units, a decrease of 52.72% from 2012; from 2020 to now, thanks to the strong recovery of China's manufacturing industry after the epidemic, the machine tool industry has multiple needs for equipment renewal and replacement of domestic machine tools. Advantage. In this case, China's machine tool industry has begun to pick up. In 2020, the output of metal-cutting machine tools in China will reach 446,000 units, and the output of metal-cutting machine tools in 2021 will reach 602,000 units, a year-on-year increase of 34.98%.

Localization of CNC machine tools

CNC machine tool is the abbreviation of CNC machine tool, which is an automatic machine tool equipped with a program control system. China is in the stage of industrial restructuring and upgrading, and advanced manufacturing will gradually replace traditional manufacturing. With the continuous upgrading and development of downstream industries, machine tool machining accuracy and accuracy stability are getting higher and higher, and the demand for medium and high-end products is also increasing. It is worth emphasizing that the localization of high-end CNC machine tools in China will accelerate.

The upstream industries of CNC machine tools are mainly machine tool parts, functional parts, electrical parts and CNC systems. Raw materials account for a relatively high proportion of the main business cost. Therefore, the fluctuation of upstream material prices strongly correlates with the industry. The rise in material prices will correspondingly increase the production cost of the machine tool industry. However, due to the wide range of downstream demand industries, the CNC machine tool industry has strong pricing power and can transfer price increases.

According to the "2023-2027 China CNC Machine Tool Industry Market Survey Analysis and Development Trend Forecast Research Report" analysis:

Market Status of the CNC Machine Tool Industry

The value of a high-end CNC system accounts for about 20%-40% of the cost of high-end CNC machine tools. Presently, domestic high-end CNC systems mainly rely on imports. Still, the functions of foreign high-end CNC systems are usually not fully open, and even export to China is prohibited, thus making my country's high-end CNC machine tool industry subject to foreign countries. Under the support and guidance of national policies, domestic companies developing high-end CNC systems have emerged and partially localized, but their market share is less than 10%.

CNC machine tool products can be divided into three categories: CNC metal cutting machine tools, CNC metal forming machine tools and CNC special processing machine tools. Among the three-segmented products, CNC metal cutting machine tools account for the largest proportion, accounting for 53.8%, followed by CNC metal forming machine tools, accounting for 28.5%, and CNC special processing machine tools accounting for 16.8%.

The competition pattern of China's CNC machine tool market is an oligopoly market. Some oligopolistic enterprises rely on capital strength and technological advantages to obtain larger market shares and profit margins. Chinese companies occupy the remaining low-end market, and the competition is fierce.

In 2020, my country exported 109,539 CNC machine tools, with a total export value of 1.106 billion US dollars. Judging from the export situation of the CNC machine tool industry from 2018 to 2020, the export volume and export value remained stable in general and decreased slightly in 2020. In 2020, my country imported 20,699 CNC machine tools, with a total import value of US$3.353 billion, and the average import price was much higher than the average export price.

Currently, the numerical control rate of output value is less than 30%, and the numerical control rate of consumption value is less than 50%. In comparison, the numerical control rate of developed countries is about 70%. CNC machine tools started late in China and originated in the 1980s. After 30 years of ups and downs, after a period of growth, it has entered a mature stage.

The market prospect of the CNC machine tool industry

With the support of national policies, Chinese domestic enterprises continue to pursue innovation, China's CNC machine tool industry has developed rapidly, and the industry scale has expanded. In 2019, the scale of China's CNC machine tool industry reached 327 billion yuan. In the future, with the development of emerging fields such as 5G equipment, new energy vehicles, and smart wearable devices, the CNC machine tool industry will usher in new development opportunities. It is estimated that by 2023, the industry scale will reach 402.43 billion yuan, a rapid growth of 8.2%.

With the accelerated transformation of China's manufacturing industry, emerging industries such as precision moulds, new energy, aerospace, rail transit, 3D printing, and biomedicine have risen rapidly. Their manufacturing process depends highly on CNC machine tools and other smart manufacturing equipment, which will become the CNC machine tool industry. New growth point. It is estimated that by 2026, the market size of China's CNC machine tools will reach 514.8 billion yuan.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

A Definitive Guide to High-Speed Machining Aluminum

A Definitive Guide to High-Speed Machining Aluminum