CNC Machined Bike Parts Manufacturer: Making Ordering Bicycle Components Easier

Sep 27,2022

Sep 27,2022

CNC machining service promotes the development of custom bicycle parts

CNC or computer-controlled numerical control machining is now trendy and has become a central focus of the global industry. It provides a gross advantage to manufacturing industries and makes production easy. Bicycle manufacturing is also adopting the new production trend of CNC machining. Almost every big auto industry uses the CNC machine for producing bicycle parts, including wheels, engine parts and many more.

The advantage of CNC machining makes it ideal for several industries, including bicycle production. Automobiles, medical equipment, aeroscopes and many more. It helps to deliver highly accurate parts according to consumer requirements.

So due to the perfection of the CNC machining process, all the delicate parts with strict designs came out with adequate accuracy. However, remember that it also has some limitations regarding the process selection, working and budgets. The manufacturer needs to focus on specific aspects of working with the CNC machining process.

In addition, the unique features of CNC machining make it acceptable for the global industry. Now, if you are new to CNC machining and want to know how it works amazingly with developing custom bicycle parts, then this guide is for you. Here we will share all about the CNC machining services, how it works and many more.

So let's dive into it.

What are CNC bicycle parts?

CNC machining, or the computerised manufacturing process, refers to pre-programmed software. It includes the codes that control the production movement and equipment. It has aggressive control over all complex designs and machinery.

Now, when we talk about bicycles or motorcycles, it includes all the metal and plastic parts. The metal and plastic parts have complex structures that make them challenging for the industries to handle. Now CNC machining makes bicycle parts production easy for manufacturers.

The bicycles include comprehensive metal parts, especially when talking about sports bikes or bicycles. The sport bicycles involve leisure activities like mountain, road, high-end, and hybrid bikes. The CNC machining helps produce all these parts, including the light and other vital metal components. Remember that these are the technical parts that handle significant weight and performance. However, every customer has different requirements regarding the bike, and Tuofa CNC Machining Manufacturer run the production according to them. Some bicycle parts include aluminium and carbon material for increasing performance. However, some also use titanium components to reduce the weight and increase the bicycle's strength. All these high-end components also include a complex design that is only suitable for CNC machining.

However, aluminium is the most used material for bicycle CNC components. It also has other materials, including stainless steel, nickel, carbon steel, copper, titanium and certain types of plastics. The CNC machining softwares handles the production of all complex bicycle components through these metal and plastic materials.

Development of CNC machining parts for the bicycle industry in 2022

CNC machining is one of the modern technologies in the upcoming years. The CNC emerged in 2019 and became the most significant thing for manufacturing industries in 2022. It reduces the production time and makes the process quicker. All the production processes through CNC manufacturing include hand in hand work with the short development cycle. As we already mentioned, it consists of the software and codes that handle the production of all simple and complex designs. So the manufacturing cycle becomes shorter and helps the industries for quick delivery.

Currently, in 2022 the development of CNC machine parts for bicycles will provide three-axis support. The manufacturer can make the three-dimensional design using the same machine and less additional work.

In the future, the CNC machinery will provide significant precision compared to current working. Still, the CNC machining parts of bicycles are incredible and provide high accuracy compared to consumer demand. One of the essential benefits for manufacturers of using the CNC machining is that it reduces the production cost and provides more accurate products in a short time.

So it will hit the bicycle development industry in 2022 and beat all the production methods in upcoming years.

Is it hard to make bicycle parts on a CNC machining?

CNC machining is a way to make the manufacturing work easy and more accurate. Many beginner industries think transferring a CNC machine from the previous production method is challenging. But keep in mind that CNC machining has the potential to use a wide variety of materials during production. At the same time, the other machines give a tough time to manufacturers when they start using a variety of materials.

The CNC machines can handle all the material in bicycle parts and help to create the elements with a wide variety and design. The manufacturer can use the bicycle parts material like steel, carbon fibre, plastic, nickel alloy and many others for the bicycle part through CNC machining.

Moreover, there are different types of CNC machines available in the market that you can consider according to your requirements. The right choice of CNC machine and software help accomplish various tasks during bike parts manufacturing and reduces the hassles.

So, it is not hard to make bicycle parts on a CNC machine, especially if you want to use different material types. Instead, it will make the production process easy and more manageable for the industry.

Which parts of a bicycle need CNC parts?

Almost most of the bicycle parts need CNC machining. The bicycle industry demands high-quality mechanical support and assemblies that help provide reliable and profitable bicycles. So the significant reliability and performance come in bikes through CNC machines. It helps to produce the value-added products that customers love and admire.

The manufacturing of bike parts through CNC machines follows the complete cycle. It starts with the CAD design of a part. After the completion of the design, the machine turns it into G-code. The CNC tool reads the G-code and carries it to the instruction unit for creating precise bike parts. Here, start manufacturing specific bike parts according to the instructions given in G-code.

Once you finish the coding and get the accurate part, you will be able to get a similar part as often as you want. The CNC machine will make an equal part for you with significant consistency, precisions and accuracy.

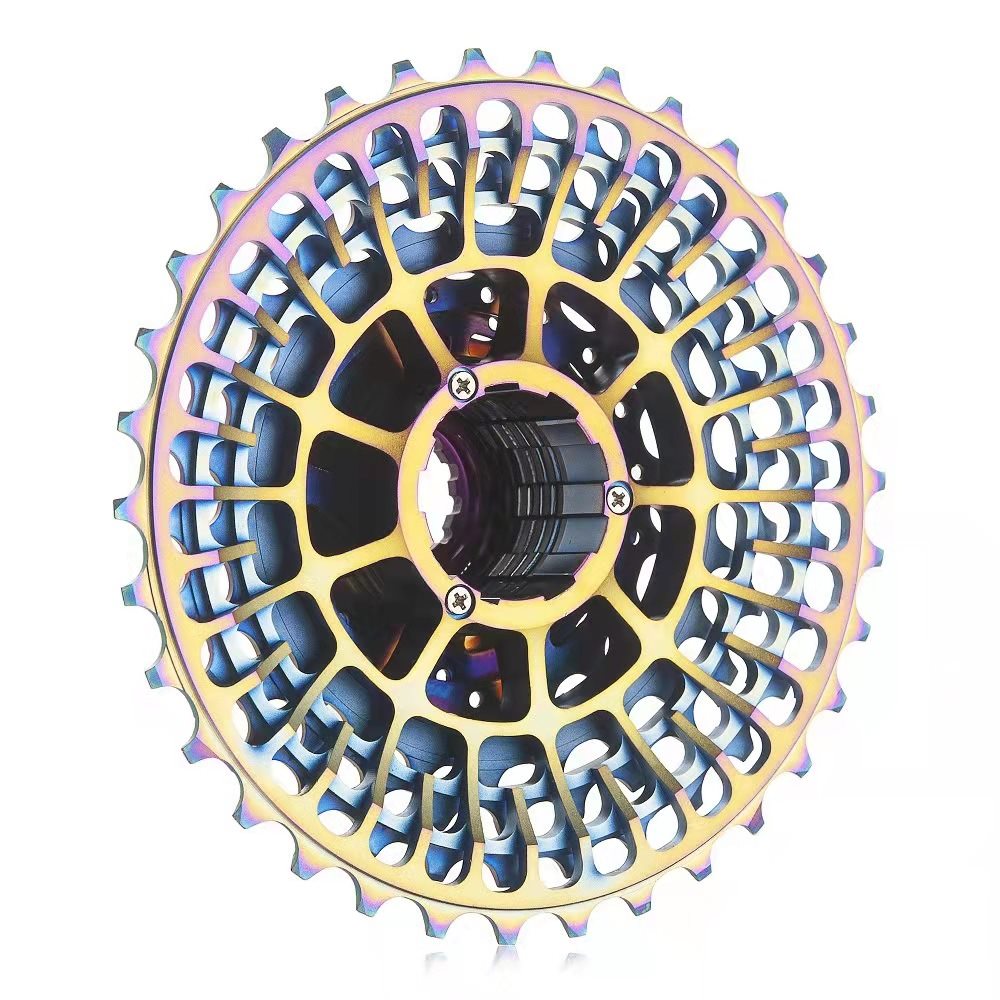

So you can make all kinds of bicycle parts through a CNC machine ranging from the frames to wheels and sprockets of the bike. Moreover, it handles diverse materials even with the customised design of the bike parts.

By summing, all the bike parts need CNC machining during their manufacturing process, including:

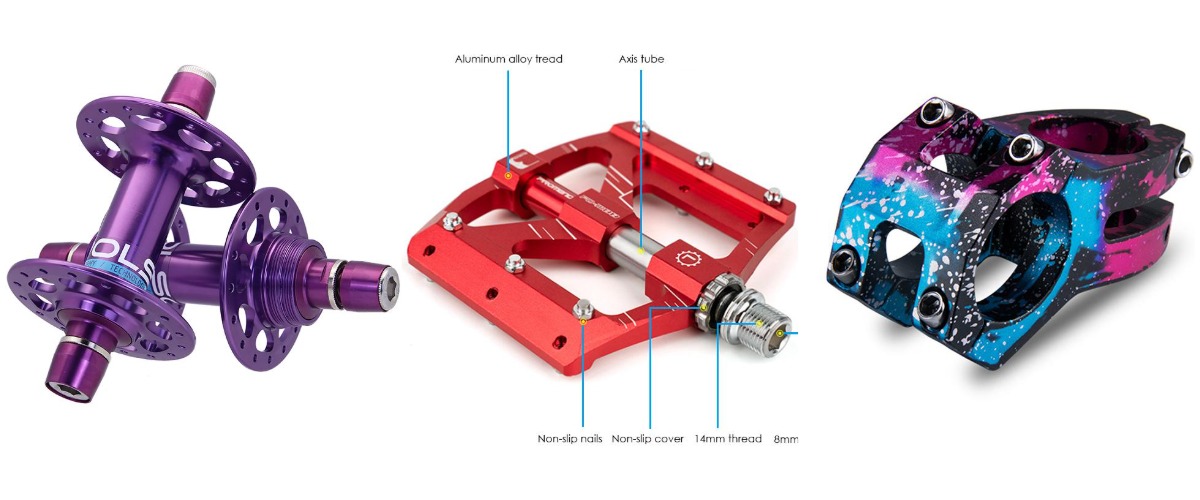

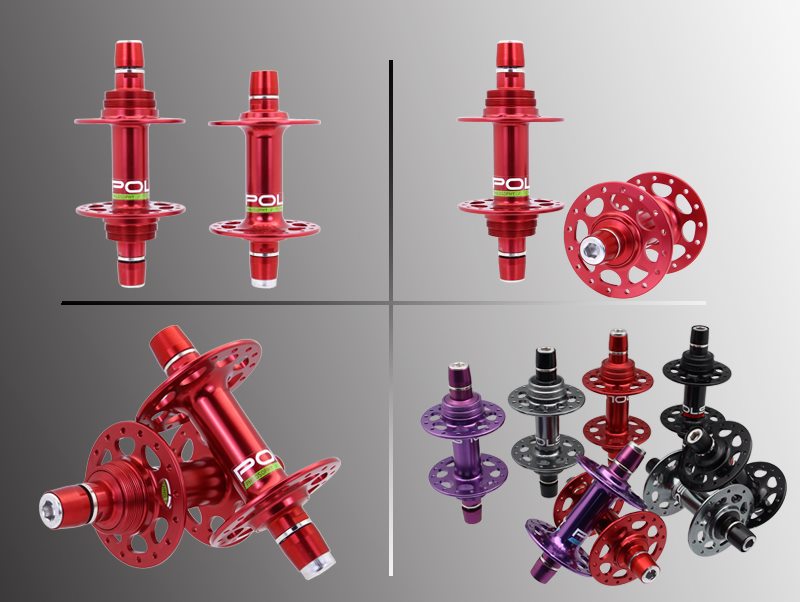

- Racing hubs

- Bicycle hubs

- Barrel adaptor

- Bike clamp

- Velocity stack

- Bike peg

- Headset adjuster

- Fort fitting of bicycle

- Forkhead fitting of bicycle

- Multi-Speed ball bearing

Now every customer demands different materials in these parts. The CNC machining helps the manufacturers meet customers' demands and provide accurate or price-worthy products.

Are custom CNC machined bicycle parts expensive?

Now it is one of the common queries that industries and customers want to know. ARE custom CNC machiningbicycle parts expensive? First, it is essential to keep in mind that machine shops significantly cut production costs when producing bicycle parts by using CNC machining. There is no doubt that CNC machinery is expensive, but still, industries can find it at a lower price and can provide leverage directly to their clients.

Initially, when the manufacturing industry instals the CNC machining, the production cost reduces as it also eliminates the requirement of the individual operator from units. So the machine shops or manufacturing industry need one expert person who can handle the machine working on several platforms. When CNC machines start working and take all the tasks with significant accuracy, it reduces the production cost. Moreover, the industries can reduce their staff or workforce and still get consistent and accurate products at a reasonable price.

So the custom CNC machined bicycle parts are not expensive. The CNC machining allows the sellers or CNC machining manufacturer to keep their bike parts cost at low rates and fall in the affordable category.

Moreover, the manufacturers also face the additional cost of generating bike parts. But the extra cost depends on the selection of CNC machining and material.

For instance, the custom CNC machining bike parts fall on thin walls with tight tolerance. The production units need to focus on certain things like tooling. But with ideal CNC machining, the manufacturers can provide affordable bike parts and not cause a burden on users.

www.tuofa-cncmachining.com Conclusion

If you are looking for customised CNC bike parts, then CNC machining development is ideal. It provides significant benefits to users and manufacturers as well. Once you are done coding a CNC machine, it will give accurate products for plenty of time. Moreover, it reduces the production cost and time for manufacturers and helps users to get authentic products.

We hope this article will help you learn about the CNC machining services and how they work in the development of custom bicycle parts.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Taking the Stainless Steel Machining Industry to the Next Level

Taking the Stainless Steel Machining Industry to the Next Level