Car Parts Machining Service: Boost Performance and Extend Lifespan

Nov 30,2023

Nov 30,2023

Since CNC machining has now become a core of manufacturing industries due to its advancement and precise control. Similarly, it is now being used for automotive machining to improve their functionality, ease of manufacturing, accuracy, and better surface finish to create tempting look. In this text, you'll gain knowledge about the world of CNC auto parts, the materials utilized, and the components machining, and the significance of quality control in the vehicle business. Also, you will find out about the advantages and disadvantages of car parts machining, the costs involved, and why China Tuofa Custom car parts is the perfect choice for all your custom car part fabrication.

Quick View of Article Content

CNC Machining Used in Automotive Industry

Advantages of Car Part Machining

What are the Limitations of Car CNC Machining?

Cost of Car Parts Machining Services

Benefits of Outsourcing Car Parts Machining Services

Why Choose China Tuofa Custom Car Parts Service

Custom car part fabrication

CNC Machining Used in Automotive Industry

CNC machining is a game-changer for the automotive industry, and it can greatly benefit you. With its precision and efficiency, CNC machining ensures that the parts used in your vehicles are of the highest quality. These computer-controlled machines allow for customization and mass production, which means that you can get exactly what you need while keeping costs down. From engine parts to interior components, CNC machining plays a vital role in creating reliable and durable solutions for your automotive needs. Experience the power of CNC machining and enjoy the benefits it brings to the automotive industry.

Types of CNC Auto Parts

Almost every structural part and other accessories involved in custom car part fabrication can be done using CNC machining. That’s why we call it an advanced machining process due to its versatile nature. Following are the few CNC auto parts manufactured:

- Cylinder heads, crankshafts and other engine components machining is done by car parts machining companies. Through this, a high-quality product is obtained with greater life expectancy.

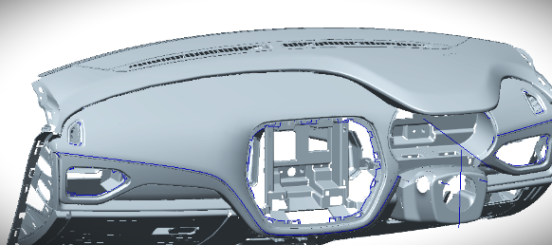

Automotive machining

- Controlling arms and other steering components, even suspension of a car can be done using CNC auto parts machining.

- Front grilles (chrome bars), dashboard, handles, and other related accessories are produced.

In the following video, you’ll find out how CNC machining is done to manufacture complex automotive parts,

Materials for CNC Machining Car Parts

Car parts machining companies aim to develop every component that aids in fulfilling the needs by making use of different materials. The following materials are frequently used for CNC auto parts machining:

- Aluminum is a light, machinable and corrosion resistant material especially in the atmosphere. It is being used for custom car part fabrication where such properties are required.

- Steel provides good wear resistance, strength, impact resistance and is being used in the manufacturing of several engine components and especially chassis which is basically the foundation of a car. For this purpose, commonly used grades of steel involve 4140, 4130, A710 etc.

- Plastic is an adaptable material used to make interior accessories like dashboard panels, headlamps, doorknobs.

Car Parts Examples

Following are some examples of automotive parts manufacturing with CNC machining service:

- Cylinder heads are essential elements of an engine's combustion process. CNC machining gives an efficient control to create the best fitment and shapes to avoid any inaccuracy.

- Brake calipers are important parts of a vehicle's braking system. Accurate production of them would give a better car control, safety and would help to avoid any noise and mishappening.

- Dashboard panels of a car not only provide a pleasant interior, but they also store different controls and gauges. CNC machining allows for the precise fabrication of these panels irrespective of complex designs.

Custom car part fabrication

Quality Control in the Automotive Industry

To assure vehicle safety and reliability, the automobile industry promotes quality control. To meet industry standards IATF 16949 certificate, car parts machining companies must adhere to strict quality control measures. To prove this, a company should have proper ISO certification to show no compromises have been made on quality and a company aims to deliver the best quality to the customers.

Advantages of Car Part Machining

CNC machining has various advantages over conventional methods of production. Among the many advantages are:

- Precision and Accuracy: The computer-controlled procedure maintains consistency and eliminates human errors and deviations.

- Modification: Components machining can be done according to one’s own demand which allows for the modification in automotive industry.

- Efficient: Multi-tasking is possible at higher accuracy which will help to save time and would increase overall productivity. Also, through automation, the risk of human errors can be avoided.

- Budget: High-scale production would result in greater cost savings. This is because of less waste, defective pieces, and the need of workforce.

- Adaptable: Since car parts machining companies aim to develop every car component so they make use of a wide range of materials involving steels, aluminum, and plastics. polymers.

What are the Limitations of Car CNC Machining?

Although automotive machining has various advantages, there are also limitations that must be considered.

- The initial investment necessary for CNC machines and equipment is significant, making it difficult for smaller car parts machining companies or individuals with limited budgets.

- Sometimes, the expected size of the required part cannot be processed through CNC as there are certain size limitations. So, the need of alternate methods arises that might fail to quality product.

Cost of Car Parts Machining Services

The cost of car machining services is determined by several criteria, including the design's complexity, the number of parts required, the materials utilized, and the level of modification. To find out the actual cost, first you need to come up with the required design or shape, then share your recommendations regarding material. The cost for CNC machining might be higher than other manual methods, but it will provide you with your desired product having great surface finish and detailing. Thus, bearing the cost for one time will provide you with greater product life.

Benefits of Outsourcing Car Parts Machining Services

It would result in favoring both ends. By cooperating with specialized companies, you obtain access to cutting-edge equipment and gain access to their experience in the newest CNC machining processes, ensuring the manufacture of high-quality components. On the other hand, it works as a strategy for an organization to stand out from the competition by analyzing the market and becoming better. Also, greater demand would result in more economical production.

Why Choose China Tuofa Custom Car Parts Service

Considering an understanding of the advantages and limitations of automotive machining, picking the right partner for your custom car part fabrication is important. China Tuofa can deliver the best products following your requirements. The lasting commitment to high-quality standards, as evidenced by ISO 9001:2015 and IATF16949 recognition, sets apart China Tuofa from other car parts machining companies.

Choose China Tuofa Customized Car Parts for top-quality automotive parts. With years of experience and expertise in CNC machining, we deliver precise and accurate components. Their advanced technology ensures they can produce complex parts with exceptional precision. Our mechanical engineers offer comprehensive customization options to meet your specific needs. Quality assurance is a priority, with a stringent process to ensure durability and reliability. China Tuofa provides competitive pricing without compromising on quality and delivers on time. Trust China Tuofa for your customized automotive parts needs. Visit tuofa-cncmachining.com for more information. Get the quotation contact now info@tuofa-cncmachining.com.

FAQ

Brake disc machining cost?

Ans. It entirely depends on the customer’s demand regarding a type of material and other specific requirements. For instance, aluminum would cost more compared to steel ones but along with that provides greater corrosion resistance and is lightweight.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

The Advantages of 316 Stainless Steel Machining for Your Business

The Advantages of 316 Stainless Steel Machining for Your Business