Automotive Wheel Hub Machining Process and Precautions

Nov 02,2022

Nov 02,2022

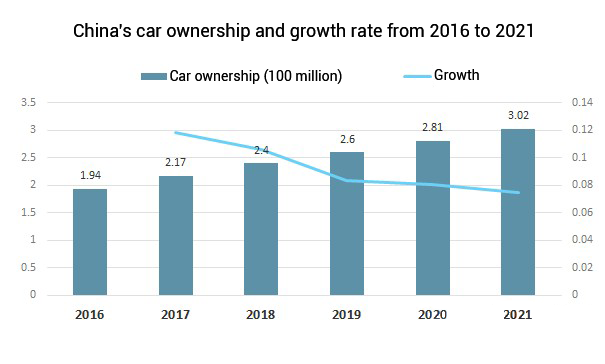

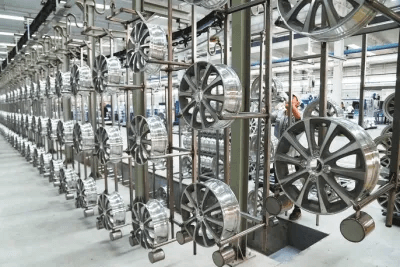

China's economic development is improving, and the number of cars is also rising. Cars have become the most important means of transportation for people's daily travel. As the core components of automobiles, the quality and performance of automobile hubs are directly related to the quality and performance of automobiles. It determines the stability and safety of the car, so it has always been the focus of most car manufacturers. In machining, as the basic core parts, the quality of the wheel hub also reflects the manufacturer's production capacity and processing level.

Nowadays, the precision of automobile wheels can reach 0.01 mm, and the speed and transmission power are already very high. This is due to the development of modern technology, which also makes more and more processes for manufacturing wheel hubs, higher and higher machining accuracy, and safety. And stability has also been greatly improved. Of course, the application of CNC machining service in the automotive industry has made a great contribution

Analysis of wheel hub parts

If the automobile wheel hub is classified, it can be classified as a disc-type part. The exposed plane is embedded in the groove in the stepped belt and is supported by the reinforcing rib, and the inside is a stepped deep hole. Therefore, for the processing of the wheel hub, it is necessary to formulate a reasonable and scientific processing method to produce the best quality wheel hub.

Wheel hub process settings

Process route design of wheel hub

The processing steps of the wheel hub are as follows:

① CNC rough machining is performed on each end face of the big end of the wheel hub;

②The end faces of the small head of the hub and its assembly stop are CNC finished;

③The bearing assembly position and brake drum assembly position of the hub are CNC fine-milled;

④ CNC machining (drilling, expanding, reaming) of the combined hole;

⑤ Inspection and repair.

Among them, the accuracy requirement of the third process is the highest.

Selection of positioning datum

In the design of an automobile wheel hub, it is very important to choose the datum positioning surface of the wheel hub. Only by ensuring that the benchmark design is accurate can the high-quality precision and quality of the hub be guaranteed. Wheel hubs are parts that are processed in large quantities, so it is necessary to ensure the stable and efficient processing of their parts to further ensure the wheel hubs' qualification rate. For the selection and positioning of the relative datum plane, it must be formulated in combination with the specific requirements of the hub.

Process design from wheel hub end face to size

Tool selection for machining hubs

The end face of the hub is the third sequence in its process route. The machine tool for this process is a vertical turning machine, and the processing tools are turning tool holders and inserts. When choosing a tool, careful consideration and careful selection should be made, and then a careful plan should be designed. At the same time, a suitable tool should be screened according to the bearing hole, and the processing failure caused by insufficient tool shank length and tooltip angle should be avoided as much as possible. . In addition, try to choose a higher-strength tool holder to avoid vibration patterns and chattering blades.

Setting of machining hub program

When programming the program, the CNC machine must stop working. In addition, it is necessary to focus on the calculation of the bearing hole position to avoid quality problems in the bearing hole as much as possible. In addition, when the tool is set, it is necessary to consider the interference and other issues to avoid the phenomenon of tool collision during the machining process. And when the tool is moving, it should not be too fast. It is necessary to debug the tools involved in the processing one by one, so as to avoid problems to the greatest extent.

Wheel hub drilling

In the selection of specifications and models of tools and machine tools, it is necessary to strictly follow the "Concise Manual of Mechanical Manufacturing Process Design" for screening, and in terms of cutting amount calculation, it is necessary to strictly follow the "Concise Manual of Cutting Amount" for technology and selection.

Casting method of the wheel hub

This article takes aluminum alloy wheels as an introduction. There are three main casting methods for aluminum alloy wheels, namely: gravity casting method, forging method, and low-pressure precision casting method. The details are as follows:

The first is the gravity casting method. This method mainly uses the action of gravity to pour the aluminum alloy solution into the wheel hub mold at one time, and after processing by related equipment, the wheel hub blank parts can be formed. The gravity casting method has the advantages of simple operation, low investment, and extremely high production efficiency, but its own shortcomings are also very obvious. Rough pitting, etc.

The second is the forging method. This method is to die-cast the aluminum ingot into the shape of the hub through the downward action of the press and the use of the mold. Compared with the gravity casting method, this method has a higher production rate. quality. Specifically, it has the characteristics of high surface finish, well-proportioned aluminum alloy density, relatively lightweight, and high strength. However, to use this method for wheel casting, equipment with good performance and quality must be selected. At the same time, the manufacturing cost and input cost of this method are relatively high, and the yield is not very high, which is basically between 50% and 60%.

The third is the low-pressure precision casting method. This method uses low pressure to make the wheel hub. This method is the most advanced method among the three casting wheel hub methods. And the surface finish of the hub produced is extremely high, the quality of the hub is very uniform and light, the yield rate is extremely high, and the quality defect is the least among the three methods.

Parameters of car wheel hubs

Although the wheel hub is small, it has many important parameters. If you do not pay attention to these wheel hub parameters, it will seriously affect the stability and safety of the car. Therefore, in the process of wheel hub processing and later maintenance, you must focus on the wheel hub. parameter. Generally speaking, the parameters of the wheel hub have five aspects, as follows:

①Size usually refers to the diameter of the hub. If the size of the hub and the flat ratio of the tire are relatively large, the car will feel better control and driving stability during driving, but although it has Very good grip, its relative tire noise will also increase, and the fuel consumption of the car will also increase accordingly.

②It is limited by the width of the wheel hub, and the choice of tires for the car will be limited to a certain extent. Although the diameter of the wheel hub will be the same, due to the different wheel width, the corresponding bandwidth of the tire will also change.

③ is the hub PCD, which is called pitch circle direct. This indicator mainly refers to the diameter between several bolts in the center of the hub. Generally speaking, there are usually five or four bolt holes in the center of the hub. The diameter of the circle formed by these holes is PCD, the pitch circle diameter. PCD is an important parameter of the wheel hub. Its design is reasonable and moderate, which can greatly improve the safety of the car and its stability during driving.

④ is the hub offset (ET), this indicator mainly refers to the specific difference between the seat of the hub center fixing bolt and the hub center.

⑤ is the center hole. This indicator mainly refers to the center position of the hub, which requires a certain degree of coaxially with the position of the concentric circle of the hub. It must be explained that the tolerance of its diameter will also affect the deviation of the center hole.

Tuofa CNC Machining Conclusion

As an important part of the car, the quality of its processing technology will directly affect the use and performance of the car. Understanding the processing technology and main processing technologies of automobile wheel hubs will help to process more suitable wheel hubs to meet the needs of automobiles.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Improvement method of CNC milling process for machining mold parts

Improvement method of CNC milling process for machining mold parts