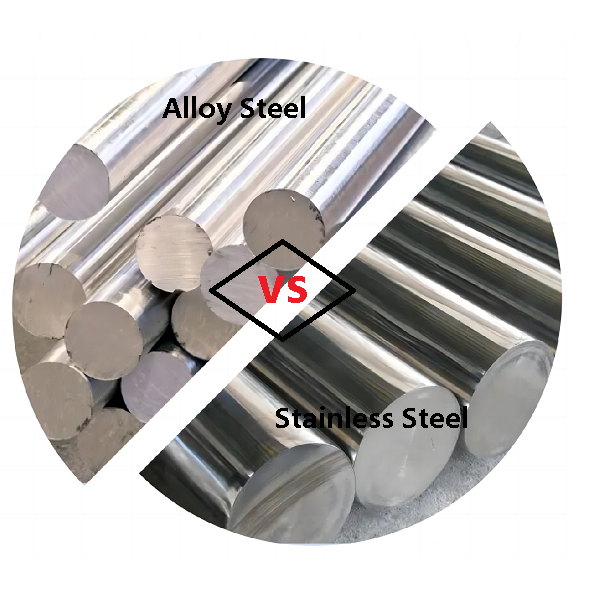

Alloy Steel vs Stainless Steel: A Comprehensive Comparison

Jul 05,2023

Jul 05,2023

Everyone knows about steel or at least heard about it. There is no confusion about it. But questions arise when you hear different names of steels like stainless steel, alloy steel, carbon steel, chromium steel and many more and you don’t know about these terms. Well, steel and alloys have Fe and C in composition. When it combines with other alloy metals it changes its name, composition, properties, and applications. Here, our main concern would be alloy and stainless steel. The article will explore basic information about these materials. This contains composition, characteristics and uses. Furthermore, this will help you to differentiate between steel and alloys. Then it can be easy for you to make choices between steel grades depending on your project.

Alloy Steel

You can understand by the name that alloy steel falls in the category of steel. These steels are combined with other alloy metals. For example, nickel, boron, silicon, chromium, vanadium, and many more. These metal alloys are introduced in the metal alloys by metal fabrication methods and heat treatment to improve mechanical properties done. These are toughness, wear resistance and tensile strength. The range of these alloy metals varies from 1-50%. Low and high alloy steels are its categories. They have a 5% difference of alloy metal in their composition. Normally, low alloy steels are preferred in manufacturing processes. These are for construction materials and other industrial applications.

The common names you must have heard in daily life about steel and alloy are carbon steel, high-strength steel, chromium steels. Other than these, stainless alloys, nickel alloys, aluminum alloys are used in metal fabrication of construction materials and other industrial applications.

Types of alloy steels

Carbon steel

Carbon steel has the main metal alloy 2.5% carbon. It is further combined with iron to form alloy. This is a common steel and alloys for industrial applications. The manufacturing processes of carbon steel are relatively economical and easy metal fabrication, and you can find it easily in market. Mild carbon steel (1.3%C) is commonly used because of its moderate properties. High carbon has very high hardness and toughness, sometimes not suitable for every industrial application. Low carbon has high ductility and low tensile strength.

Nickel alloy steel

Nickel alloys have a variety of compositions in steels. This varies its mechanical properties. It also increases its corrosion resistance. Nickle itself has low corrosion resistance. But when it is added with other metal alloys like iron, tungsten, and copper, the alloy metal becomes very resistant. Nickel alloy steels have greater resistances than stainless alloys.

Molybdenum alloy steel

It increases the strength of steel. Steel contains 0.2-0.3%Mo. It still imparts great effect and makes ultra-high strength steel. These steels can bear strength up to 150Tons. This makes it suitable for high temperature applications in the aerospace industry. When a small amount of nickel is further added to this steel, they become high corrosion resistant. These steels have many applications in chemical industries.

Vanadium alloy steel

Vanadium alloys have high strength, lower weight, and high durability. It has most industrial applications as automotive components, construction materials, and in manufacturing processes of heavy machinery components. Vanadium is normally produced by calcium reduction process. It is a white colored metal and has a bright surface.

|

Metal alloys |

Percentage in steel |

AISI grade |

|

Carbon steel |

2.5% C |

10XX |

|

Nickle alloy steel |

3.5-5% Ni, 0.65-1.57% Cr |

23XX, 25XX, 31-33XX |

|

Manganese alloy steel |

1.75% |

31XX |

|

Chromium alloy steel |

0.25-1.05%Cr |

41XX |

|

Molybdenum alloy steel |

0.2-0.3% Mo |

40XX, 46XX, 48XX |

|

Vanadium alloy steel |

0.8-0.95% Cr, 0.1-.15%V |

61XX |

YouTube link: https://www.youtube.com/watch?v=lV0FtuQnNow

How strong is alloy steel?

Heat treatments and metal fabrication techniques are utilized to make strong ally steel. These manufacturing processes impart high mechanical properties in metal alloy such as toughness, tensile strength, hardness, and wear resistance. They become high-strength steels and are good as construction materials and industrial application. Mechanical properties are important factors of steel and alloy. These are to measure how much strength a metal alloy can survive in any industrial application. Alloy metals alone do not have toughness and tensile strength. These are increased by adding metal alloys like stainless alloys, nickel alloys, aluminum alloys, titanium alloys. The impact of these metal alloys is further described in the table below and it will help you explain how strong alloy steel is.

|

Alloy metal |

Impact on mechanical properties |

|

Silicon alloys |

Increase mechanical properties and strength |

|

Aluminum alloys |

Increase corrosion resistances |

|

Nickel alloys |

Increase toughness, hardness, and corrosion resistances |

|

Manganese alloys |

Increase hardness and oxidation, high temperature and corrosion resistance |

|

Chromium alloys |

increase temperature and corrosion resistance |

|

Tungsten alloys |

Increase tensile strength, hardness, high temperature resistance. |

|

Niobium alloys |

Increase corrosion resistances |

|

Vanadium alloys |

Increase corrosion resistances and hardness |

Stainless steels

Stainless steel has Cr more than 13%. It also has alloy metal Ni and Mo more than 7%. These have high corrosion resistance, mechanical properties, and easy metal fabrication. Corrosion is prevented by an oxidation layer made over the surface of steel. Oxygen present over the steel in the form of oxides prevents the corrosion from forming. This layer can become weakened due to various environmental factors and servicing conditions. But can be overcome with different methods. Stainless alloys are famous construction materials. It also has many industrial applications. They provide high toughness, tensile strength, hardness, weldability, wear, and corrosion resistance with easy manufacturing processes. Different metal alloys are also added to increase mechanical properties. These can be nickel alloys, aluminum alloys, and titanium alloys.

Stainless steel grades

stainless steel has many categories. Here you will see the categories based on composition.

Austenitic stainless steel

It has Cr more than 17% with C, Ni, O, N and Mn. They have an austinite phase and little ferrite phase in their structure. The hardness is not affected by heat treatments in these grades. However, coldworking can improve their mechanical properties like toughness, tensile strength, weldability, and wear resistance. Corrosion resistance is also exceptional in these steels. The common grades are 301, 302, 303, 304, 316, and 347.

Ferritic stainless steel

They contain iron in their structure in the form of ferrite and other secondary phases in little amounts. The ferritic phase is also stable at room temperature due to sufficient chromium and other alloy metals. They have a high iron in their microstructures. Nitrogen and carbon are also present in small amounts. The hardness is not affected by heat treatments in these grades. The common grades are 409, 430, 434, 439, 442, 444, and 446.

Martensitic stainless steel

Chromium is present in 10.5% with other metal alloys. These are nickel, manganese, carbon, nitrogen. Hardness is not affected by heat treatments in these grades but have good mechanical properties like toughness, tensile strengths, weldability, and wear resistances. Corrosion resistances can be increased by different manufacturing processes for industrial applications. Common grades are 410, 420 and 440.

Duplex stainless steels

They contain 22% Cr and other metal alloys like Nickle, molybdenum, and nitrogen. They contain both phases austenite and ferrite with the ratio of 50-50%. That is why it is named Duplex steels. They have higher corrosion resistance than other steel grades. The hardness cannot be increased by heat treatments. Common duplex stainless-steel grades are Forta DX 2304, Forta LDX 2404.Forta LDX 2101 & Forta EDX 2304.

YouTube link: https://www.youtube.com/watch?v=xvZdcucQDAE

Difference between alloy steel and stainless steel

Alloy steels and stainless alloys are very different materials. Some are explained as:

Chromium

Stainless steel has Cr asmain metal alloy. It is around 17-25% in stainless steel. Alloy steels have lesser chromium around 2-4%.

Higher tensile strength

Alloy steels have higher tensile strengths. This is because of the presence of man different metal alloy which individually have their own tensile strengths. While stainless steel has Cr as primary metal alloy.

Weight

Alloy steels are lighter in weight than stainless alloys. They also have higher strength than stainless alloys. Therefore, this makes a good option for many industrial applications.

Stronger and more durable

Alloy steels are stronger. They are also more durable. Alloy metals are present in a large amount in alloy steels. That produces them good for industrial applications where strength and durability is required. Alloy steels make high strength steel.

Corrosion Resistance

Stainless alloys have greater corrosion resistance. High Cr amount produces them extremely corrosion resistant. Alloy steels have less Cr.

Alloy steel vs stainless steel knife

Alloy steels make better knife. They have high mechanical features. But can be expensive. Hence, stainless steel knives are better and economical.

Price

alloy steels have high cost than stainless alloys. They contain huge amounts of metal alloy which are expensive. While stainless steel has overall less cost. The metal fabrication and readily availability is a good feature for their industrial applications.

Weldability

Stainless steels have higher weldability. Alloy steels have many metal alloys and can cause difficult weldability. The metal fabrication of stainless alloys is easy. As they have higher ductility.

Machining

Machining stainless alloy is easier because of higher ductility. Therefore, they have easy metal fabrication. The manufacturing processes of stainless alloys are less complicated.

Alloy Steel vs Stainless Steel Applications

Alloy Steels

Alloy steel has a great use in the pipe fabrication process. They have high application in energy related sector due to high strength and toughness. It is used for making kitchen appliances. These are like toasters, cookware, pans and containers where high temperature and corrosion chances are involved.

Carbon steel is used in building bridges and skyscrapers. It is also considered as a main material in oil and gas industries.

Low alloy steels are used in aerospace and automotive fields. They are good structural material. They are used in making pipes and railway lines. High strength steel is used in many industrial applications. As they have high corrosion resistance.

Stainless alloys

Stainless steel is used in auto parts. It is also used in transport industries. It is used in making components like trims, grills, and exhaust systems, ship containers, rankers and in making different parts of ships and vehicles. It is preferred due to its high corrosion resistances. It also has less maintenance and is cost-effective.

In the medical field, it is preferred for making surgical tools due to being corrosion resistant. Other than that, it is used in making different machinery parts in MRI scanners and CT scans and as dental implant material.

It is also a good construction material due to easy manufacturing processes, weldability, and versatility. It is also a recyclable material therefore suitable for a sustainable environment.

It is used in food processing industries and is a demandable material for making kitchen items. It is used in making utensils, faucets, cabinet, and kitchen appliances.

Which is Better Alloy Steel or Stainless Steel?

Alloy steels are better than stainless alloys. They have higher mechanical properties. It has higher toughness, strengths, and wear resistances. That’s why it is suitable for many industrial applications.

Does alloy steel rust?

Yes, alloy steels can rust. If iron is present in a heavier amount in alloy steel than the other metal alloys, then there is a high chance of their rust. Stainless alloys have better corrosion resistance properties.

Advantages and disadvantages of alloy steels

Alloy steels have better mechanical properties than stainless alloys. They are more durable and stronger. They impart good toughness, strengths, hardness, and wear resistances. Therefore, they are preferred material in many industrial applications.

The cons of alloy steel are low corrosion resistances. They have less Cr which increases the corrosion resistance in alloys. Another disadvantage is that they are expensive. Cost-effectiveness is important in industrial applications where bulk materials and production are involved.

Advantages and disadvantages of stainless steels

Stainless alloys have exceptional weldability and corrosion resistance. Therefore, they are preferred for many domestic applications. They are also cheap and cost-effective material. It is one of the common materials you find around yourself in daily life.

stainless steels have lower mechanical properties than alloy steel. The less metal alloys make it lower strength material for many industrial applications.

Factors Affecting Performance

There are many factors affecting the performance are heat treatment, environment, temperature, pH, and manufacturing processes.

Stainless steel has lesser effect by heat treatment. Their properties do not change much by heat treatments. Being corrosion resistant, environment and pH also have lesser effect on their performances. The manufacturing process has a great effect on their performance and mechanical properties.

Alloy steel can be affected by heat treatment, pH, environment, working temperature and manufacturing processes. There are many alloy metals added to them. Every metal alloy has different reactions to different conditions. Therefore, their performance can be affected by all these factors.

Why Choose Tuofa for Custom steel parts

Alloy steel is better than stainless alloy. It has superior mechanical properties. It has higher toughness, tensile strengths, wear resistance. It is suitable for many industrial applications. Because it has high strength to weight ratio.

Stainless alloys have exceptional corrosion resistance and weldability. Therefore, they are preferred for many domestic applications. They are also cheap and cost-effective material.

If you are looking for a reliable source of alloy steel or stainless steel for your project, TUOFA CNC Machining offer great services of prototyping machining and custom machined part of alloy steel or stainless steel. high precision machining is available for 3D printing, sheet metal prototyping and fabrication of alloy steel or stainless-steel products.

FAQs

Is alloy steel a good metal?

Yes, alloy steel is a good metal. It is useful for high strength applications. It contains many metal alloys which are suitable for a variety of industrial applications and as a construction material.

Alloy steel vs stainless steel for cooking

Stainless steels are better for cooking. It offers higher corrosion resistance than alloy steel. Furthermore, it is more economical and cost effective for domestic applications.

low alloy steel vs stainless steel

low alloy steels are superior. They offer higher mechanical properties than stainless steel. They have higher toughness, tensile strength, and wear resistances. They are high strength steels. The heat treatments increase their performances.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

304 vs 430 Stainless Steel: A Comparative Guide

304 vs 430 Stainless Steel: A Comparative Guide