A514 Steel: Properties, Applications, and Advantages

Jul 18,2024

Jul 18,2024

ASTM A514 grade is specially designed for structural applications in construction. It is also utilized in machinery and equipment. This grade has a combination of moderate strength, wear and tear resistance, toughness, corrosion resistance and is suitable for long term applications. There are various grades of ASTM A514 like A, B, E, F, H, Q and S. A514 steel properties are exceptional for heavy duty applications.

What is A514/T-1 Steel?

ASTM A514 steel plates are known for its higher strength, weldability and toughness.it is a low carbon steel available in quenched and tempered state having high performance in structural applications and suitable for high wear machines uses.

Variants of A514 Steel (A514B, A514F, etc.)

A514 grades are also known as T1 steel. it is quenched and tempered to increase strength and thus has 8 variants A, B, E, F, H, Q, P and S. Their mechanical properties are the same but can vary with the thickness and have different chemical properties. These A514 grades have high weldability and machinability.

Industry Standards and Certifications

A514 grades meet the standards of ASTM A514. It is mostly recognized by ASTM standards which also covers quenched and tempered quality. There is not any specific ISO an EN standard for A514 steel. It is also known as T1 steel and T1 metal in tempered and quenched

Advantages and Disadvantages of Using A514 Steel

Advantages

ASTM A514 has unique chemical composition which provides higher toughness and strength. T1 metal is more responsive to heat treatment than carbon steel. The heat treated T1 steel is more wear and tear resistant and has higher durability. The most important feature is its long-lasting nature which makes it a cost-effective option. T1 metal saves the project cost in the long run.

This high strength steel has high impact resistance and corrosion resistance which makes it a good option for high abrasion and impact resistance applications.

Disadvantages

There is no such drawback associated with ASTM A514 grades. But there is a limitation that it is sensitive to diffusible hydrogen. This implies it is prone to hydrogen cracking. This normally occurs after the welding of steel.

Chemical Composition of A514 Steel

The chemical composition of ASTM A514 varies with A514 grades. The compositions of all the A514 grades are as:

|

Elements (max) |

Grade B |

Grade S |

Garde H |

Grade Q |

Grade E |

Grade F |

Grade A |

Grade P |

|

Carbon |

0.21% |

0.21% |

0.21% |

0.21% |

0.2% |

0.2% |

0.21% |

0.21% |

|

Manganese |

1% |

1.5% |

1.3% |

1.3% |

0.7% |

1% |

1.1% |

0.7% |

|

Phosphorus |

0.030% |

0.03% |

0.03% |

0.03% |

0.03% |

0.03% |

0.03% |

0.03% |

|

Sulfur |

0.030% |

0.02% |

0.03% |

0.03% |

0.03% |

0.03% |

0.03% |

0.03% |

|

Silicon |

0.35% |

0.45% |

0.35% |

0.35% |

0.4% |

0.35% |

0.8% |

0.35% |

|

Nickle |

- |

- |

0.7% |

1.5% |

- |

1% |

- |

1.5% |

|

Chromium |

0.65% |

- |

0.65% |

1.5% |

2% |

0.65% |

0.8% |

1.2% |

|

molybdenum |

0.25% |

0.60% |

0.3% |

0.6% |

0.6% |

0.6% |

0.28% |

0.6% |

|

Vanadium |

0.08% |

0.06% |

0.08% |

0.08% |

- |

0.08% |

- |

- |

|

Titanium |

0.08% |

- |

- |

- |

0.1% |

- |

- |

- |

|

Boron |

0.10% |

0.005% |

0.005% |

- |

0.0005% |

0.006% |

0.0025% |

0.005% |

|

Copper |

- |

- |

- |

- |

- |

0.5% |

- |

- |

|

Zirconium |

- |

- |

- |

- |

- |

- |

0.15% |

- |

Main Alloying Elements

Main alloying elements in ASTM A514 grades are carbon which increases toughness and durability, manganese that decreases brittleness, phosphorus which increases machinability, silicon which increases corrosion resistance and sulfur which increases corrosion resistance and machinability in A514 steel properties.

Trace Elements

Boron is present in traces which increases hardness in A514 steel properties.

Mechanical Properties of A514 Steel

The mechanical features in A514 steel properties vary with the thickness in section. These are explained below:

Yield and Tensile Strength

The tensile and yield strength along with other features in A514 steel properties are:

|

Mechanical properties |

Up to ¾’’ |

From ¾’ to 2-1/2” |

From 2-1/2 to 6” |

|

Yield strength |

100ksi |

100ksi |

90ksi |

|

Tensile strength |

130ksi |

130ksi |

130ksi |

|

Elongation |

18% |

18% |

16% |

|

Reduction in area |

40% |

40% |

50% |

A514 Hardness

The hardness in A514 steel properties is normally expressed in Brinell hardness. For all the thickness it is ranged in 235-293HBW.

Hardness Testing Methods

Brinell hardness test of A514 consists of applying load up to 3000kg for a specified time period up to 30sec. This load is applied by a tungsten carbide ball with a diameter of 10mm. The indentation of applying load tells the hardness of the T1 steel.

Toughness

Toughness defines the capacity of a material to absorb energy. It depends on strength and ductility. ASTM A514 has high tensile strength and has good ultimate tensile strength of 110ksi which indicates it has good toughness as well.

Impact Resistance and Testing (Charpy V-Notch Test)

Charpy V-notch test measures the absorbed energy by material. it is done by breaking the sample by an impact loading. The tightly secured sample of ASTM A514 is stroked by a hammer on a pendulum arm at both ends. This measures the maximum absorb energy. A514 steel properties shows high impact resistance, toughness and strength.

Applications of A514 Steel

The application of ASTM A514 steel are as:

Construction Industry

It is a common material to use in transport trailers, agricultural equipment and for heavy vehicle frame and chassis. It is also used in crane booms, mobile man lifting, and as welded bridge structural members.

Manufacturing Industry

T1 steel plates are used in building frames and for structural parts. It is used in high wear machines parts which require high impact and abrasion resistance. it is used to make truck frames and bodies, storage tanks and containers frames.

Military and Defense

T1 metal plates are used in machinery manufacturing for military and defense industries. it is also used on petrochemical, nuclear and offshore platforms. It is best option for the applications where the materials are exposed to high pressure and high temperature environments.

Mining Industry

T1 steel is well suited for mining applications like when require large tooling, digging, scraping etc. the scraper bars are used for coal mining conveyers. Rock scrapers blades and bucket scraper in large scale mining normally uses ASTM A514. Because it has high wear and abrasion resistance. conveyers flight in coal mining also uses T1 metal.

Fabrication and Welding of A514 Steel

The fabrication and welding of T1 metal are as:

Cutting and Machining

A514 has good toughness and strength, therefore it is difficult to machine sometimes. But it can be machined with conventional methods. When cutting and machining T1 steel, water soluble coolant and low speed is recommended. Carbide tooling is recommended instead of high-speed steel.

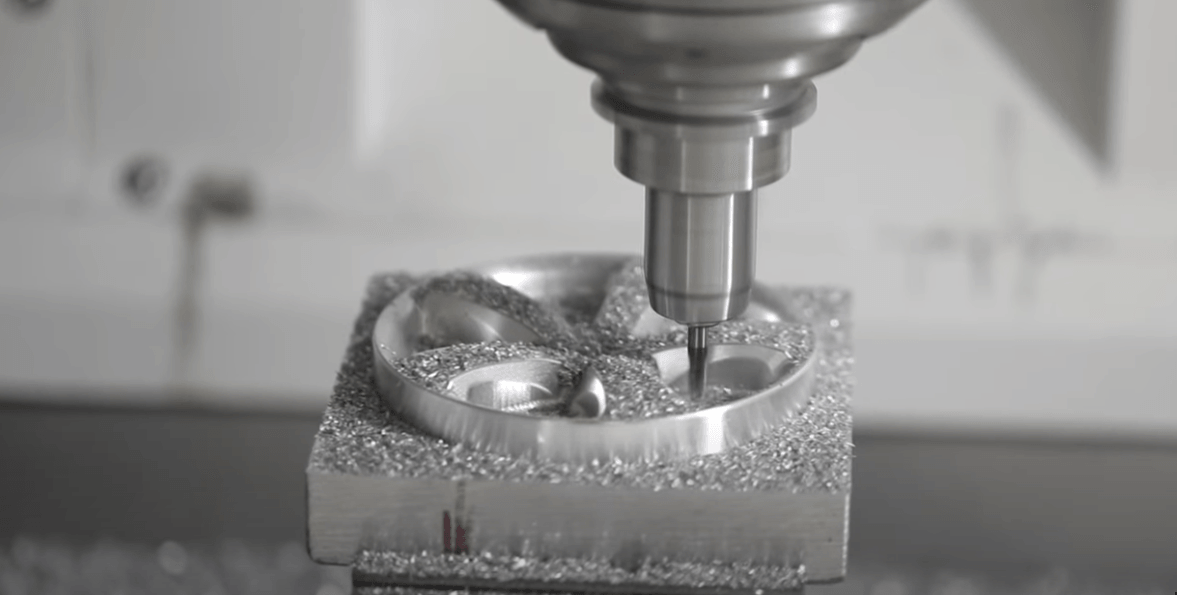

CNC Machining Techniques

A514 steel properties include good machining and gives great response in cnc machining. Tuofa CNC machining offers great services for A514 machining. Please visit: http://tuofa-cncmachining.com/

Welding Techniques

ASTM A514 steel can be welded by conventional method like SMAW, GMAW and etc. it is recommended to take extra care of heat affected zone due to high toughness. Low hydrogen welding rods are recommended to use to avoid hydrogen cracking. Post weld treatments may reduce the risk of hydrogen cracking.

Preheating and Interpass Temperature

Low hydrogen weld rods are required to use and the interpass temperature must be less than 450degF during welding. The preheating must be less than 150degress for T1 metal plate of 1.5” thickness. Preheating and interpass temperature must be controlled carefully.

Heat Treatment

T1 steel is heat treated for stress relieving using quenching and tempering. The quenched or tempered ASTM A514 is known as T1 metal or T1 steel. this heat treatment involves high temperature heating and then rapid cooling in water or oil. This process increases A514 steel properties. the ASTM A514 grades can be strengthened by cold working and strain hardening.

Recommended Filler Metals

The major concern is the hydrogen content in filler metals. The recommended filler metal must not deposit weld metal with diffusible hydrogen more than 8ml/ 100gm.

Comparison with Other High-Strength Steels

A514 steel properties are compared with other high-strength steel. the common grades are compared below

A514 Steel vs. AR500 Steel

AR500 steel has high wear and impact resistance even at low temperatures. ASTM A514 is designed for high strength applications.

A514 Steel vs. S690QL Steel

ASTM A514 is high strength low alloy steel. it is designed for heavy duty applications S690QL is a quenched and tempered high strength low alloy steel which has good weldability and ductility.

A514 Steel vs. A572 Steel

A514 is known for high strength and heavy-duty applications. A572 has moderate to high strength levels. It is used where strength and ductility both are required.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

H13 Tool Steel: Properties, Applications, and Machining Considerations

H13 Tool Steel: Properties, Applications, and Machining Considerations