410 Stainless Steel vs 304: Identifying Key Differences

Apr 17,2024

Apr 17,2024

Stainless steel is developed between the late 1800s and early 1900s. The development is a significant milestone due to the alloying of chromium in steel which has significantly improved its corrosion resistance. Stainless steel of different grades offering different properties is widely used in different industries. This article would help the reader to understand the properties and applications different between 410SS and 316SS. This information would help you to decide to choose the best grade between 300 series and sus410 steel that gives the best properties you are looking for in your application.

AISI 410 Stainless Steel

Sus 410 steel contains 11.5-13.5% chromium content which provides it good passivation and makes it moderate corrosion resistant. Sus 410 steel has gone through different heat treatments to enhance its hardness and toughness. Sus 410 steel is martensitic that’s why has good mechanical properties making it suitable for industries like power generation, automotive, and petrochemical.

Image showing industrial piping done from 410 stainless steel.

YouTube video explaining 410 martensitic stainless steel.

https://www.youtube.com/watch?v=KMD21Yw_mxg&pp=ygUbNDEwIHZzIDMwNCBzdGFpbiBsZXNzIHN0ZWVs

Is 410 stainless steel magnetic?

Yes! Sus 410 steel is martensite in nature making it magnetic in all directions.

AISI 304 Stainless Steel

From 300 series of stainless steel 304SS has 18.00% - 20.00%chromium content and is also named as 18-8 stainless steel. This presence of chromium allows it to make a passivation layer protecting it from the outer environment. 304 Stainless steels from the 300 series show excellent mechanical properties, formability, weldability, and corrosion resistance. 304 Stainless steel is austenitic stainless steel. 304 stainless steel is mainly used in applications like food processing, kitchen appliances, architecture, automotive, and chemical and petrochemical industries [4].

Catering equipment is made from 304 stainless steel.

Is 304 stainless steel magnetic?

304 stainless steel is austenitic stainless that's why shows little or no magnetic properties.

What are the Differences Between Stainless Steel 304 and 410

410 stainless steel composition

|

Element |

AISI 410 Stainless Steel (%) |

AISI 304 Stainless Steel (%) |

|

Carbon (C) |

0.15 - 0.25 |

≤ 0.08 |

|

Silicon (Si) |

≤ 1.00 |

≤ 0.75 |

|

Manganese (Mn) |

≤ 1.00 |

≤ 2.00 |

|

Phosphorus (P) |

≤ 0.040 |

≤ 0.045 |

|

Sulfur (S) |

≤ 0.030 |

≤ 0.030 |

|

Chromium (Cr) |

11.50 - 13.50 |

18.00 - 20.00 |

|

Nickel (Ni) |

- |

8.00 - 10.50 |

Table showing composition of 410ss vs 304ss.

410 vs 304 Stainless Steel Properties

Density

The density of 304 stainless steel compared to 410 stainless steel is higher. 304 stainless steels have a density of 8.00 g/cm³ while sus 410 steel is 7.75 g/cm³.

Strength

The martensitic nature of sus 410 stainless steel provides it higher strength while the soft austenitic nature of 304 stainless steel provides it less strength compared to sus 410 steel.

Hardness

Similar to strength, the hardness of the Sus 410 steel is higher due to its martensitic nature compared to 304 stainless steel.

Tensile Strength

Sus 410 steel is martensite that's why has higher strength compared to austenitic stainless steel 304. 410 stainless steel has 760 MPa tensile strength and may change depending on heat treatments while 304 has 515 MPa because it's authentic and soft.

Yield Strength

Yield strength of sus 304 is 215MPa while that of sus 410 steel is 275 MPa.

YouTube video showing what is best 410 ss vs 304 ss for exhaust system.

https://www.youtube.com/watch?v=oId-fXqk5mU&pp=ygUbNDEwIHZzIDMwNCBzdGFpbiBsZXNzIHN0ZWVs

410 vs 304 Stainless Steel Corrosion Resistance

- Martensitic vs Austenitic Stainless Steels

Martensite stainless steel has a BCC crystalline structure which is formed by the heat treatment process of heating it at high temperature and then quenching it in water. This heat treatment makes martensitic stainless steel hard and tougher making it suitable for the fabrication of turbines and valves. Austenitic stainless steel is FCC structure and is soft. Austenitic stainless steel has excellent durability, ductility, corrosion resistance, and formability making it suitable for the aerospace, pharmaceutical, food, and beverage industries.

- How 410 SS Reacts to Corrosive Materials

At moderate and low corrosive environments 410 SS shows excellent corrosion resistance but at high temperatures and extreme corrosive environments in presence of Cl ions it shows pitting corrosion when a passive layer of 410 SS is damaged.

- Corrosion Resistance of 304 SS

304 SS shows very good corrosion resistance compared to 410 stainless steel. 304SS is austenitic stainless steel and is the best choice to use in moderate to extreme corrosive environments. It shows the best corrosion resistance to pitting and crevice corrosion.

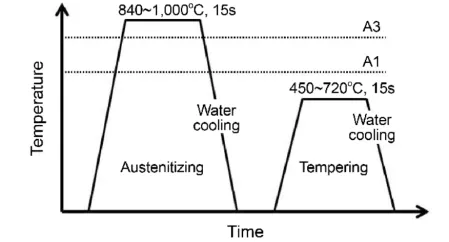

Hardened by Heat Treatment

- Quenching

The stainless steel is heated to a high temperature and then rapidly cooled in water or oil. This step is done to increase the hardness of the steel.

- Tempering

After quenching stainless steel is tempered by reheating it near crystalline temperature. This process is done to remove thermal stresses from the stainless steel. Tempering would provide ductility and softening to quenched material.

Image showing quenching and tempering chart.

Weldability

304 stainless steel due to its austenitic nature is ductile and shows ease of fabrication that's why is easy to weld compared to martensitic 410 SS which is hard so preheating may be required before welding it.

Machining service

304 stainless steel shows excellent machining properties due to its ductile nature while 410 shows poor machining properties because it's hard and may show cracking while machining.

Durability and Cost

304 shows high durability and is more expensive compared to 410 stainless steel. Although 410 SS is less expensive initially but requires more maintenance cost compared to 304 SS.

Summary AISI 410 vs 304: A Comparative Chart

|

Property |

AISI 410 Stainless Steel |

AISI 304 Stainless Steel |

|

Composition |

|

|

|

Carbon (C) |

0.15% - 0.25% |

≤ 0.08% |

|

Chromium (Cr) |

11.50% - 13.50% |

18.00% - 20.00% |

|

Nickel (Ni) |

- |

8.00% - 10.50% |

|

Mechanical Properties |

|

|

|

Tensile Strength (MPa) |

480 - 760 |

515 |

|

Yield Strength (MPa) |

275 |

205 |

|

Hardness (HRC/HRB) |

20-30 (annealed), >50 (hardened) |

70-85 (annealed) |

|

Corrosion Resistance |

|

|

|

General Corrosion |

Moderate |

Excellent |

|

Resistance to Chlorides |

Susceptible |

Resistant |

|

Applications |

|

|

|

Industrial tools and equipment |

✓ |

- |

|

Pump and valve components |

✓ |

- |

|

Cutlery and kitchen utensils |

✓ |

✓ |

|

Automotive parts |

✓ |

✓ |

|

Architectural applications |

- |

✓ |

|

Food processing equipment |

- |

✓ |

|

Chemical processing equipment |

- |

✓ |

YouTube video showing the difference between 304ss vs 410 ss.

https://www.youtube.com/watch?v=ce1U4P8HHxc&pp=ygUbNDEwIHZzIDMwNCBzdGFpbiBsZXNzIHN0ZWVs

Advantages and Limitations of Stainless Steel 410 and 304

|

Aspect |

AISI 410 Stainless Steel |

AISI 304 Stainless Steel |

|

Advantages |

|

|

|

Corrosion Resistance |

Moderate |

Excellent |

|

Strength |

High |

Moderate |

|

Durability |

Robust |

Exceptional |

|

Cost |

Economical |

Higher |

|

Machinability |

Fair |

Excellent |

|

Weldability |

Moderate |

Excellent |

|

Limitations |

|

|

|

Chloride Resistance |

Limited |

High |

|

Toughness |

Lower |

Relatively Lower |

|

Temperature Resistance |

Limited |

High |

|

Application Range |

Specific |

Versatile |

Which is Better 304 or 410 Stainless Steel

304 ss vs 410 ss both have different properties and are useful for different applications. Sus 410 steel is suitable for application where high mechanical properties are required while 304 SS is suitable where high corrosion resistance property is required.

Stainless Steel Hardware: Choosing Between 410 and 304

410 ss is harder and difficult to machine and shows moderate corrosion resistance while 304 shows excellent corrosion resistance and ease of fabrication. The specific material selection between 410 ss and 304 ss for hardware fabrication would depend upon the requirement of the properties for that hardware.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Titanium vs Tungsten: Which is Better

Titanium vs Tungsten: Which is Better