2205 Stainless Steel vs 316: What is Better

May 14,2024

May 14,2024

Everyone of you must be familiar with 316 stainless steel and duplex steel 2205. But there is a chance you do not know the key differences and important features of these steel grades for marine application and for corrosion resistance. This article will explore these aspects highlighting their properties, pros and cons and other applications.

Overview Duplex Stainless Steel and 316

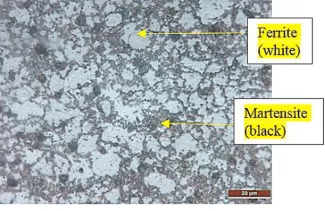

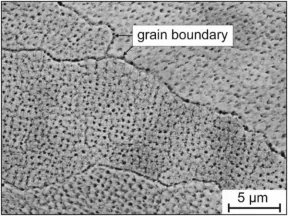

Alloy 2205 refers to super duplex stainless steel. It is composed of slightly higher amount of chromium 22% along with nickel and molybdenum 5% and 3%, respectively. It has dual phases of ferrite and martensite. It is magnetic in nature due to ferrite. Corrosion resistance of alloy 2205 is remarkably high and it is the best fit for marine applications. Common uses are shipbuilding, offshore oil platforms and wind turbines. High strength to weight ratio and low thermal expansion of duplex 2205 makes it more demanding for cryogenic applications.

316 stainless steel is an austenitic alloy. It has up to 18% chromium, 14% nickel and 3% molybdenum. It is nonmagnetic in nature. Corrosion resistance and formability properties of 316 alloy are high. It has the most applications in the food processing industry due to high corrosion and high temperature resistance. Medical devices and tools are mostly made of 316 grades because they have less reactivity with body fluids. High toughness makes it demanding in industrial sectors as well.

Applications(used)

Corrosion resistance of 316 stainless steel is high and sometime refers as marine stainless steel due to many applications in marine industry. These include shipbuilding, boat hulls, piping and offshore devices. Chemical industry and energy industry have high demands due to high strength and corrosion and high temperature resistance. 316 is also one of the preferred materials in medical and pharmaceutical industry because of high biocompatibility. Surgical implants are normally made of 316 due to cost effectives and no reactivity with body fluids.

Alloy 2205 duplex steel has high strength and ductility. It is utilized in building bridges and structures. It is used to make pressure vessels due to high durability and crevice corrosion resistance. 2205 has exceptional resistance to chloride stress corrosion and to acetic acid. This makes it suitable for the oil and gas industry, chemical industries and in desalination plants. It is most suitable for harsh environments applications where there is a high chance of corrosion.

Advantages and Limitations of Stainless Steel 2205 and 316

Both are great in their applications and therefore have many advantages. However, there are some limitations which are discussed below:

Advantages and Limitations of 2205 Stainless Steel

Alloy 2205 has a major advantage in its cost effectiveness. It is less costly compared to other alloys with the same or lesser properties. It has high crevice corrosion resistance, stress corrosion and acetic acid resistance due to high Ni and Mo content. Therefore, it is considered marine stainless steel. alloy 2205 has very high strength. This implies thinner section of alloy has strength equivalent to other steels with thick cross sections. Other than this, weldability of ally 2205 is higher than many steel grades which are normally not easily weldable.

Limitation of duplex steel includes is its low toughness at low temperatures below 50℃. It has dual phase which limits is working also at temperatures greater than 250℃. Because it starts forming intermetallic phases which affects its properties like weldability.

Advantages and Limitations of 316 Stainless Steel

316 steel grade has high corrosion resistance due to high Cr and Mo content. This makes it highly resistant to acetic acid, crevice corrosion, and stress corrosion. The non-magnetic nature of 316 steel makes it suitable for the food processing industry. Because it cannot attract any dirt and is easy to clean. The formability and weldability of 316 is also higher than other austenitic grades which are used for piping system and structural support.

316 steel has limitations of its cost because of high Cr and Mo content and hence high corrosion resistance. Furthermore, it is not suitable for making intricate geometries and sharp bends because of its brittle nature at low temperature.

What are the Differences Between 2205 and 316 Stainless Steel

1. Composition

The main difference between 2205 and 316 lies in their composition. 2205 has dual microstructural phase of ferrite and austenite. 316 is austenitic grade material. alloy 2205 has 22% Cr, 5% Ni and 3% Mo. Ni is sometimes added more to increase corrosion resistance. 316 has 18% Cr, 14% Ni and 3% Mo.

2. Properties

Alloy 2205 has higher strength, ductility impact resistance and fatigue strength. It is excellent stress corrosion cracking and acetic acid resistance. 316 and 2205 both are considered marine stainless steels. 316 has many chemical and food processing and medical applications. It has lesser tensile strength than 2205 but has better ductility and toughness. Chloride corrosion resistance is also better in 2205 steel.

3. Cost

Normally alloy 2205 is more costly than 316 steel. dual phase microstructure increases its corrosion resistance and mechanical properties which makes it expensive.

2205 Stainless Steel Chemical Properties

|

Chemical |

Percentage |

|

Cr |

22% |

|

Ni |

6% |

|

Mn |

3.5% |

|

Mo |

3% |

|

N |

2% |

|

P |

0.3% |

|

C |

0.03% |

316 Stainless Steel Chemical Properties

|

Chemical |

Percentage |

|

Cr |

18% |

|

Ni |

14% |

|

Mn |

2% |

|

Mo |

3% |

|

N |

0.1% |

|

Si |

0.75% |

|

S |

0.03% |

|

C |

0.08% |

2205 vs 316 Stainless Steel Physical Properties

|

Physical properties |

2205 |

316 |

|

Density |

0.278 lb/in3 |

0.285lb/in3 |

|

Yield strength |

65ksi |

30ksi |

|

Tensile strength |

90ksi |

75ksi |

|

Modulus of elasticity |

27.6x106 psi |

29x106 psi |

|

Thermal expansion coefficient |

7.5x106 in/inᵒF |

9.2X106 in/inᵒF |

|

Specific heat |

0.112BTU/lb/ᵒF |

0.11BTU/lb/ᵒF |

|

Thermal conductivity |

8.7BTU/hr/ft2/ft/ᵒF |

10.1BTU/hr/ft2/ft/ᵒF |

|

Electrical resistivity |

22.5Ωm.in |

29.1Ωm.in |

|

Hardness |

|

95HB |

|

Elongation |

25% |

40% |

|

Weldability |

good |

good |

|

Corrosion resistance |

Higher |

high |

|

Cost |

High |

less |

Summary 2205 ss vs 316 ss: A Comparative Chart

|

Properties |

2205 |

316 |

|

Microstructure |

Dual phase- ferrite and austenite |

Single austenite phase |

|

Composition |

22% Cr, 5% Ni and 3%Mo |

18% Cr, 14% Ni and 3%Mo |

|

Mechanical properties |

High tensile, yield, fatigue strength and impact resistance |

High toughness and formability |

|

Corrosion resistance |

Marine stainless steel with high crevice, stress corrosion and acetic acid resistance |

High chloride resistance and marine stainless steel |

|

Cost |

Expensive |

Cheap |

|

Applications |

Marine industry, construction, harsh environment with high chloride content |

Food processing, chemical industry, marine industry medical and pharmaceutical industry |

Is 2205 Stainless Steel Better than 316 and 316L?

Yes, 2205 is better in many ways than 316. Super duplex stainless steel 2205 has high Cr and Mo, N content which makes it more corrosion resistant. Corrosion resistance is almost twice as much as 316 stainless steels has. Furthermore, dual phase increases its strength and durability.

Summary

Stainless steel has become the most construction material globally such as in. Therefore, many grades of stainless steel have been introduced till date. Its application has become particular in every field depending on the grades and their properties. this has become a necessity to know the major differences in commonly used grades to get the maximum benefit of the material in our project.

This article helped you understand the key differences between 2205 and 316 stainless steel for your project.

Now you can make an informed decision about which material is best suited for your needs. Here's a quick breakdown:

Need superior corrosion resistance, especially in harsh marine environments? Choose 2205 stainless steel. Its higher chromium, nickel, and molybdenum content make it the champion for resisting chloride stress corrosion, acetic acid, and other challenges.

Looking for a more cost-effective option with good overall corrosion resistance and formability? 316 stainless steel might be a better fit. It's widely used in food processing, medical devices, and other applications where hygiene and cleanability are important.

Project demands high strength and ductility? 2205 shines again with its superior strength-to-weight ratio and ability to handle pressure.

Working with intricate geometries or low temperatures? 316's better formability and low-temperature toughness might be advantageous.

Ultimately, the best choice depends on your specific project requirements. This article has equipped you with the knowledge to weigh the pros and cons of 2205 and 316 stainless steel, allowing you to select the material that delivers optimal performance and value for your project.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

410 Stainless Steel: Material Properties, Uses

410 Stainless Steel: Material Properties, Uses