Surface Finishing Service: Process & How Does it Work

Surface finishing is the process of utilizing different techniques to alter the surface of an object.

Surface finishing is a broad range of industrial processes that alter the surface of a manufactured item to achieve a certain property, Finishing processes may be employed to improve appearance, adhesion or wettability, solderability, corrosion resistance, tarnish resistance, chemical resistance, wear resistance, hardness, modify electrical conductivity, remove burrs and other surface flaws, and control the surface friction.

Surface finishing processes can be categorized by how they affect the workpiece:

- Removing or reshaping finishing

- Adding or altering finishing

Benefits of Metal Surface Finishing Process

The functions of metal surface treatment can be summarized as follows:

- Improve the appearance

- Add specific beautiful colors

- Change the luster

- Enhance chemical resistance

- Increase wear resistance

- Limit effects of corrosion

- Reduce friction

- Remove surface defects

- Cleaning the parts

- Serve as a primer coat

- Adjust the sizes

Different Types of Metal Finishes - Metal Surface Finishing Services Available at Tuofa

Do you want your CNC parts to be more corrosion-resistant or get a specific look? Here are the introductions to different types of metal finishes, more details please feel free to contact us.

For custom surface finishes such as electroplating or polishing, please contact:

info@tuofa-cncmachining.com

Tuofa Precision Machining Shop of Surface Finishing Capabilities

Here is a list of standard surface finishes. For custom surface finishes such as electroplating or polishing, please contact.

Machining parts, as-machined

Tuofa, as the CNC machining manufacturer you need, standard finish is “as machined” finish. It has a surface roughness of 3.2 μm (126 μin). All sharp edges are removed and parts are deburred. Tool marks are visible.

|

Color |

Custom surface finishes services |

|

Texture |

Custom surface finishes services |

|

Surface preparation |

Deburring |

|

Material |

All materials |

Bead Blasting

Media blasting uses a pressurized jet of abrasive media to apply a matte, uniform finish to the surface of parts.

|

color |

Custom surface finishes services |

|

Texture |

Custom surface finishes services |

|

Surface preparation |

|

|

Material |

Aluminum, Steel, Stainless Steel, Brass, Copper |

Anodizing

Anodizing is an electrolytic passivation process that grows the natural oxide layer on aluminum parts for protection from wear and corrosion, as well as for cosmetic effects. We are better than the most 3D printing parts manufacturers.

|

color |

Clear, black, grey, red, blue, gold |

|

Texture |

Smooth, glossy finish |

|

Price |

|

|

Material |

Aluminum, steel, stainless steel, brass |

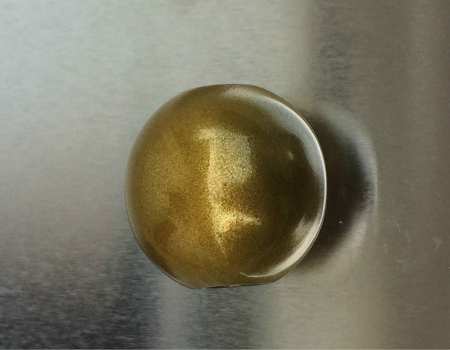

Electroplating

Nickel plating is a process used to electroplate a thin layer of nickel onto a metal part. This plating can be used for corrosion and wear resistance, as well as for decorative purposes.

|

color |

Gold, silver, nickel, copper, brass |

|

Texture |

Smooth, matte finish |

|

Price |

|

|

Material |

Aluminum, Steel, Stainless Steel, Brass, Copper |

Polishing

Custom CNC machining parts are manually polished in multiple directions. The surface is smooth and slightly reflective.

|

color |

n/a |

|

Texture |

Smooth, glossy finish |

|

Price |

|

|

Material |

All materials |

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. Take a look on our metal stamping services.

|

color |

Custom surface finishing services |

|

Texture |

Glossy |

|

Price |

|

|

Material |

All metal materials |

Brushing

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes.

|

color |

n/a |

|

Texture |

Satin |

|

Price |

|

|

Material |

ABS, Aluminum, Brass, Stainless Steel, Steel |

Painting

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic.

|

color |

Custom |

|

Texture |

Gloss, semi-gloss, flat, metallic, textured |

|

Price |

|

|

Material |

Aluminum, Stainless Steel, Steel |

Black Oxide

Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance.

|

color |

Black |

|

Texture |

Smooth, matte |

|

Price |

|

|

Material |

Steel, Stainless Steel |

Alodine

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passes and protects the aluminum from corrosion. It is also used as a base layer before priming and painting parts.

|

color |

Clear, Gold |

|

Texture |

Same as before |

|

Price |

|

|

Material |

Aluminum |

Part Marking

Part marking is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production. No other sheet metal companies are better than us.

|

color |

Custom |

|

Texture |

n/a |

|

Price |

|

|

Material |

All materials |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home