China On-demand and Rule-based Manufacturing Services

Tuofa's CNC machining shop offers the following CNC machining services for our customers:

● Prototype Machining & Custom Machined Parts

● Precision CNC Machining & 3D Printing Service

● Sheet metal Prototyping & Sheet metal Fabrication Service

● Surface Finishing Part Marking & Batch Manufacturing Service

Application of Lean Manufacturing

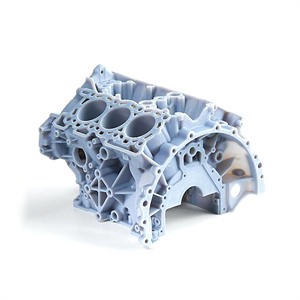

Tuofa's CNC machining workshop has more than 50 milling machines and lathes, which means we always have machining capabilities and very competitive prices. It also means we can produce complex prototypes and a wide variety of low-volume precision cnc parts, including a variety of metals and plastics, and in many surface finishes.

Why Choose Tuofa Precision Machining Manufacturer to Custom CNC Parts?

Looking for a reliable quick-turn supplier of machined plastic and metal components? Tuofa CNC precision manufacturing shop has 50+ of CNC machines, Our unmatched in-house capacity ensures your parts are shipped on-time every single time, Our ISO9001-certified CNC machining facilities are designed for both rapid prototyping and low-volume production of end-use components.

Our Machining Experience in Numbers

Tuofa has 18 yera experience in CNC manufacturing services in China and can offer one-stop service (CNC machining parts & CNC machining prototype) for you. Tuofa CNC shop not only has advanced equipment , but also have a professional team of experienced engineers operators and inspectors to make the your design come true.

Need Help with Your Parts Design?

Our team of engineers can help optimize existing designs across manufacturing processes, including Online CNC machining service, CNC milling machining, CNC lathe machining, sheet metal custom service.

Compare Our Digital Manufacturing Services

| Service | Lead Times | Materials | Tolerances | Max Part Size |

| CNC Machining Service | 1-10 days | Metal and plastic | 0.0004 in. | 18.9 in. 29.6 in. 8 in. |

| Sheet Metal Fabrication | 3-15 days | Metal and plastic | 0.003 in. | 18.9 in. 29.6 in. 8 in. |

| 3D Printing Service | 1-3 days | Metal and plastic | 0.003 in. | 18.9 in. 29.6 in. 8 in. |

Materials Used in CNC Machining Applications

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances:±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

- Price: $$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size:200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

- Price: $$$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Mild Steel

Mild steel has a wide range of uses due to its good machinability and low cost. Most grades can be cold-formed or hot-rolled. Mild steel is used for parts that may be surface hardened but do not have a stringent core strength.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Inconel

Inconel is a precipitation-hardening alloy that exhibits high-yield stress and excellent resistance to fatigue and creep. Due to its high oxidation resistance and high strength at high temperatures, Inconel is widely used in the aerospace industry, especially as a material for producing gas turbine engine rotors.

- Price: $

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Alloy Steel

In order to improve the strength, toughness, hardenability, weldability, and other properties of steel. Alloy steel is divided into low alloy steel (alloy elements less than 5%); medium alloy steel (alloy elements are at 5%-10%); high alloy steel (alloy elements are greater than 10%) according to the content of alloy elements. Generally speaking, the higher the alloy content, the better the performance of the steel and the higher the price.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Tool Steel

Tool steels are characterized by their durability, high hardness, high wear resistance and resistance to deformation, as well as their ability to retain their cutting edges at high temperatures and withstand impact without deformation.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Invar

Invar expansion coefficient is small, strength and hardness are not high, thermal conductivity is low, plasticity and toughness are high, which has unique advantages in making carbon fiber composite molds.

- Price: $$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

- POM

- Nylon

- ABS

- PEEK

- PTFE

- PC

- HDPE

- PVC

- PMMA

- PET

- PP

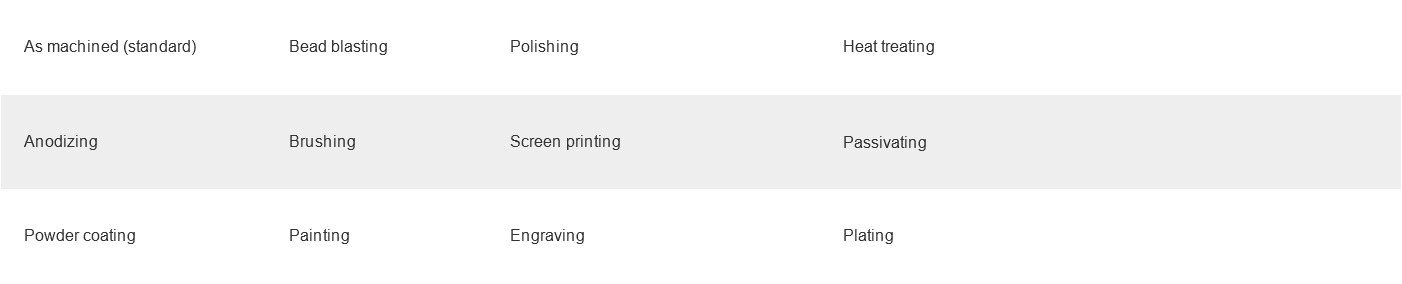

03. Finishing and Post-Processing With Manufacturing

On-Demand Lean Manufacturing Industries

Startups and multinational corporations choose to form a long-term partnership with Tuofa CNC Machining Inc. The following industries use this manufacturing technology to enhance their product competitiveness:

Quality Commitment and Solution

At Tuofa precision machining shop it is our aim to deliver high quality parts that matches your requirements and expectations. However if your order fails to meet your specifications you will be covered with our Rework and Refund Policy.

You will be able to raise any issues within 5 business days of receiving your parts. Our order fulfillment team will resolve these issues as quickly as possible typically within 1-3 business days.

Precision Machining Advantages and Challenges

Because CNC machining doesn’t require the creation of expensive molds, Tuofa can begin production far sooner than they can with other processes., CNC machining is highly automated, enabling production both during and outside work hours with minimal input from human workers. What’s more, multiple CNC machines can work from the same design simultaneously producing identical parts, ultimately shortening production lead times and saving on costs.

Tel/WeChat:

Tel/WeChat:  Email:

Email: