Plastic Types Guide: Prototype and Production of Plastic Parts

The alternative to metal is plastic. Using different types of plastic materials can help you save 25% to 50% of your costs.

China Tuofa manufactures plastic prototypes and mass-produced products that have high strength, consistent reliability and the ability to be manufactured to the same tight tolerances as metal.

Plastic Types Comparison

According to the different uses of various plastics are divided into general-purpose plastics and engineering plastics, the output of general-purpose plastics accounts for more than 90% of the output of the whole plastic materials.

When using plastic materials instead of metal, you first need to understand what are the core performance indicators of your product? Which indicators can be relaxed? Which ones can be discarded? What indicators will be affected by the material replacement? Can it be compensated by the design approach? Therefore, material replacement is a comprehensive and systematic issue.

General Purpose Plastics

General purpose plastics generally refer to plastics with large production volume, wide application, good moldability and low price, and the consumer products used in our daily life are made of these general purpose plastics. That is, polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS) and ABS.

Engineering Plastics

Engineering plastics are able to withstand certain external forces, have good mechanical properties and resistance to high and low temperatures, good dimensional stability, can be used as engineering structures of plastics, such as polyamide (PA), polycarbonate (PC), polyformaldehyde (POM), polytetrafluoroethylene (PTFE), polyetheretherketone (PEEK), etc.

Plastic Material Solutions

ABS

ABS Advantages

ABS is a very good overall resin with high impact strength and surface hardness over a wide temperature range, higher heat deflection temperature than PA and PVC, and good dimensional stability.

ABS Applications

ABS materials are used in machinery, automobiles, electronics and electrical appliances, instruments, textiles, construction and other industrial fields.

POM

POM Advantages

POM is a high density thermoplastic engineering plastic. It has excellent friction resistance. It is comparable to steel and lighter in weight than steel.

POM Applications

Telephone housings, plastic keypads, pulleys and housings for household appliances, shower heads, and fuel expansion tanks.

Nylon

Nylon Advantages

Nylon has superior abrasion resistance compared to other fibers, followed by its elasticity, which is comparable to that of wool, and its light weight, with a specific gravity of 1:14.

Nylon Applications

Nylon can replace copper and other metals in the manufacture of bearings, gears, pump vanes and other parts in the mechanical, chemical, instrumentation and automotive industries.

PTFE

PTFE Advantages

PTFE has a long-term temperature range of -200 to 250°C. It also has excellent electrical insulation properties and is not affected by temperature or frequency.

PTFE Applications

Corrosion-resistant pipes, vessels, pumps, valves, high-frequency communication equipment, radio equipment, etc. with high performance requirements.

PEEK

PEEK Advantages

PEEK, the United States UL certification long-term use temperature of 260 ℃. Even when the temperature reaches 300 ℃, can still maintain excellent mechanical properties.

PEEK Applications

PEEK is used to manufacture valve plates, springs, pumps, clutch parts, copier parts, and printed circuit boards.

Polycarbonate

Polycarbonate Advantages

Polycarbonate has significant optical properties, with a light transmission rate of about 90%, close to that of glass but lighter, less fragile, and easier to process.

Polycarbonate Applications

Polycarbonate is used in electrical, electronic, and automotive manufacturing industries at a rate of 40%-50%. The average annual growth rate of polycarbonate glasses consumption has been maintained at more than 20%, showing a great market demand.

Polyethylene

Polyethylene Advantages

PE is a thermoplastic with the advantages of high strength-to-weight ratio and good elongation.

Polyethylene Applications

PE materials are used in household appliances, electronic products, sports equipment, tableware, toys, etc.

Garolite G-10

Garolite G-10 Advantages

Garolite G-10 materials are non-conductive, non-absorbent, exceptionally strong and resistant to wear, and very light in weight.

Garolite G-10 Applications

For structural supports, mechanical insulation, gears, washers, gaskets, electromechanical components, toolholders, and other precision machined parts.

PEI

PEI Advantages

Polyetherimide is a super engineering plastic with optimum resistance to high temperatures and dimensional stability. The balance of performance and processability provides flexibility and freedom for innovative pairs of engineering designers.

PEI Applications

PEI materials are used in the electronics, electrical and aerospace industries, as well as in traditional products and as metal substitutes for cultural and lifestyle products.

ASA

ASA Advantages

ASA is an antistatic material with mechanical properties similar to ABS resin, but it has more than 10 times the aging resistance of ABS.

ASA Applications

ASA is used in bathroom and sanitary products, hot and cold water exchangers, outdoor furniture, and automotive exterior mirror housings.

TPU

TPU Advantages

TPU material is transparent, elastic, a class of polymer material between rubber and plastic, and can replace soft PVC to meet the environmental requirements of more and more fields.

TPU Applications

Manufacture of various gears; seals (mainly for wear and oil resistance); anti-vibration parts; bushings; bearings.

PETG

PETG Advantages

PETG has 3 to 10 times the impact strength of polyacrylate, high transparency and good gloss compared to PVC, and environmental advantages.

PETG Applications

PETG is used in indoor and outdoor signage, storage shelves, vending machine panels, furniture, construction and machinery baffles, etc.

PLA

PLA Advantages

PAL is a new biodegradable material, recognized as environmentally friendly, with good hardness and gloss.

PLA Applications

PLA materials account for over 66% of applications in food packaging and tableware, followed by medical and personal care at 28%.

Resin

Resin Advantages

Resin is the main raw material for manufacturing plastics, and the material is environmentally friendly and pollution-free and has good thermal conductivity and heat dissipation.

Resin Applications

Resin is used to make molds and prototypes so that the mechanical properties of products can be quickly responded to and the production efficiency of projects can be improved.

Try Tuofa Now!

Tuofa Engineer Support Team - Real human quotes are more accurate than software quotes

Plastic Components Manufacturing Process

If you need custom plastic components, our mechanical engineers have 17 years of experience manufacturing plastic parts, giving you greater design freedom and lower procurement costs.

Plastic Parts to Final Product

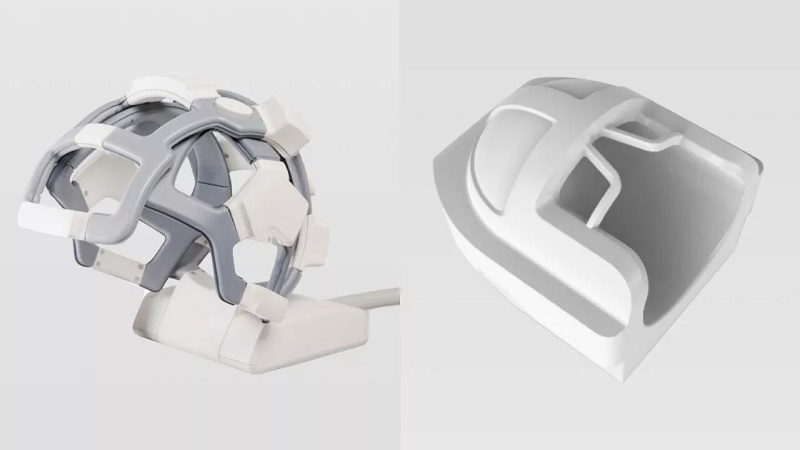

Medical

Based on environmental protection and product use efficiency, high quality, pollution-free, and convenience have gradually become new trends in the development of medical plastic products.

Aerospace

In order to fly stably in the sky and to reduce the structural weight of airplanes and drones, Tuofa selects plastic materials that are small in size but can achieve absolute reliability and safety.

Automotive

The use of plastic parts in automobiles makes the vehicle lightweight, which can reduce the weight of the vehicle and improve fuel economy.

Consumer ELectronics

The advent of 5.5G will undoubtedly require consumer electronic devices to have more powerful heat dissipation and smaller size, which will drive the renewal of plastic materials.

Industrial Machinery

Due to the advancement of technology, we demand more and more performance from our machinery and equipment, Tuofa selects new metal alloys to be applied to industrial machinery to reduce the consumption of resources.

Robotics

We develop new methods and principles to use functional soft materials to solve the seamless interface of bionic prostheses that allow robots to safely and effectively interact with the environment.

Do you know what material is the most used plastic product, but have you understood the suitability of this material for your project?

Choose the most appropriate plastic material to start your project based on the temperature and humidity of the environment in which the plastic product will be used, and the purpose of the product.

Custom Plastic Products Quote

Innovative Plastic Manufacturing

Lightweight technology will bring innovations to the development of the plastics manufacturing industry. In the future, lightweight materials will be more and more widely used in automobiles, aircraft, rail transit and other fields; precision is the embodiment of advanced molding technology in the plastic product processing industry, which is of great significance to the development of the industry; clean production and ecology are the key factors for the plastic processing industry Energy saving and emission reduction has opened a new stage.

Custom Plastics Parts Experts

With the development of engineering plastics, new high-strength and lightweight materials, your custom plastic parts can be used in construction and real estate, automotive, home appliances, or consumer electronics, medical devices, and other industrial fields.

Tuofa is an expert in custom plastic parts, plastic products that are lightweight, recyclable and green, relying on our innovative plastic manufacturing process, and advanced machinery to open up the future market for your plastic products .

Top 8 Heat-Resistant Plastics

1. Fluoroplastics What is Fluoroplastics?

Fluoroplastics refers to plastics made of fluorine resin. Common main varieties are polytetrafluoroethylene (PTFE), tetrafluoroethylene - ethylene copolymer (ETFE), polyperfluoroethylene propylene (FEP), polyvinylidene fluoride (PVDF), etc.. The use temperature is between 150℃ and 260℃. What is Polyaryletherketone?

Polyaryletherketone (PAEK) is a polymer made of a phenylene ring connected by ether and ketone bonds. It can be divided into polyether ether ketone (PEEK), polyether ketone (PEKK), polyether ketone (PEK), polyether ketone ether ketone (PEKEKK) according to the number and order of ether groups and ketone groups. |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home