Polycarbonate Machining Complete Guide

Polycarbonate(PC) has many functions as a safe and non-toxic plastic material, and its existence has advanced the development of industry with a high status.

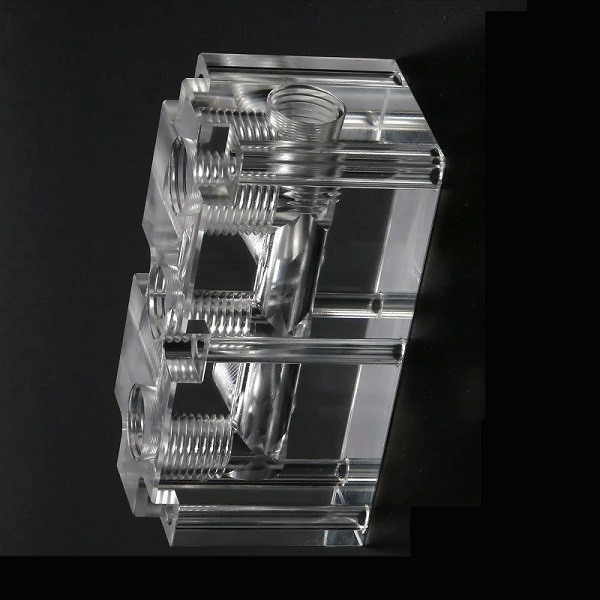

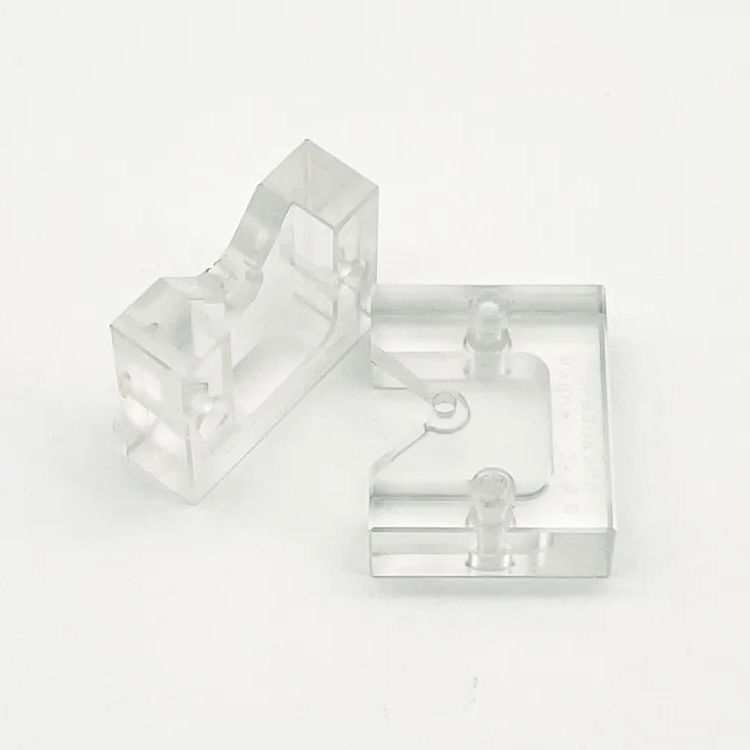

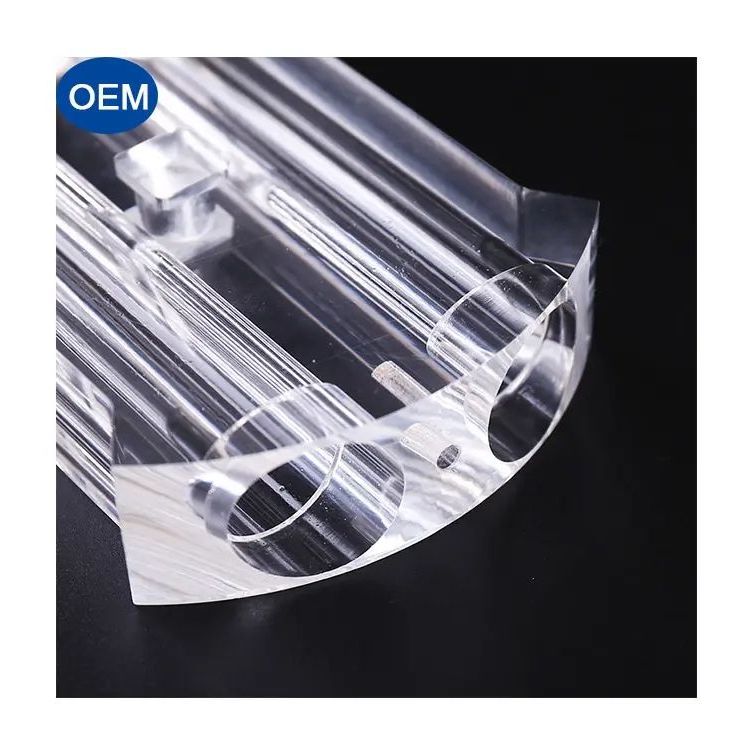

The polycarbonate machining process means that it is CNC turning, cut, drilled, milling and ground. If you have high precision requirements for polycarbonate parts, then CNC polycarbonate is particularly suitable for your project.

What is Polycarbonate

Polycarbonate is a high strength and transparent thermoplastic resin material. As the fastest growing engineering plastic, Polycarbonate materials has the best impact resistance of any plastic.

Advantages of Polycarbonate Material

Polycarbonate Parts for Lean Manufacturing

Choose us custom polycarbonate parts and enjoy the excellent quality of precision machining! We are a professional plastics CNC machining factory in China with advanced equipment and rich processing experience.

Whether it is small or large parts or complex shapes, we strive for excellence, pay attention to every detail, and ensure the precision and quality of each product through strict quality control standards and processes.

Custom Polycarbonate Parts Quote

Polycarbonate Material Properties

| Properties | Numerical value | Unit |

| Glass transition temperature | 150 | ℃ |

| Specific heat capacity | 1.17 | J/(g.℃) |

| Thermal conductivity | 0.24 | W/(m .℃) |

| Tensile strength | 60-70 | MPa |

| Elongation | 60-130 | % |

| Bending strength | 100-120 | MPa |

| Flexural modulus | 2.0-2.5 | GPa |

| Brinell hardness | 150-160 | Kgf |

| Density | 1.18-1.22 | g/cm3 |

| Melting point | 230 | °C |

Polycarbonate Applications

Industrial Machinery: polycarbonate material has many advantages such as light weight, low running noise, corrosion resistance, etc., and it has the characteristics of low manufacturing cost and flexible design. Through CNC machining, 3D printing, molding and other processes can be used to manufacture a variety of gears, racks, worm wheels, worm gears, bearings, cams, bolts, levers, crankshafts, ratchets, as well as some mechanical equipment shells, covers and frames and other transparent parts.

Industrial Machinery: polycarbonate material has many advantages such as light weight, low running noise, corrosion resistance, etc., and it has the characteristics of low manufacturing cost and flexible design. Through CNC machining, 3D printing, molding and other processes can be used to manufacture a variety of gears, racks, worm wheels, worm gears, bearings, cams, bolts, levers, crankshafts, ratchets, as well as some mechanical equipment shells, covers and frames and other transparent parts.

Automotive Manufacturing: automobile manufacturing industry: polycarbonate has good impact resistance, thermal distortion resistance, and good weather resistance, high hardness, so it is suitable for the production of various parts of cars and light trucks, which are mainly concentrated in lighting systems, instrument panels, heating panels, defrosters and bumpers made of polycarbonate alloy, etc.

Automotive Manufacturing: automobile manufacturing industry: polycarbonate has good impact resistance, thermal distortion resistance, and good weather resistance, high hardness, so it is suitable for the production of various parts of cars and light trucks, which are mainly concentrated in lighting systems, instrument panels, heating panels, defrosters and bumpers made of polycarbonate alloy, etc.

Aviation and Aerospace: with the rapid development of aviation and aerospace technology, the requirements for various components in aircraft and drones are increasing, making the application of PC in this field is also increasing. According to statistics, only one Boeing-type aircraft used polycarbonate parts up to 2,500, single aircraft consumption of polycarbonate about 2 tons.

Aviation and Aerospace: with the rapid development of aviation and aerospace technology, the requirements for various components in aircraft and drones are increasing, making the application of PC in this field is also increasing. According to statistics, only one Boeing-type aircraft used polycarbonate parts up to 2,500, single aircraft consumption of polycarbonate about 2 tons.

Medical Devices: since polycarbonate products can withstand disinfection by steam, detergents, heating and large doses of radiation without yellowing and physical property degradation, they are widely used in artificial kidney hemodialysis equipment and other medical devices that need to operate under transparent and intuitive conditions and require repeated disinfection, such as the production of high-pressure syringes, surgical masks, disposable dental appliances, blood separators, etc.

Medical Devices: since polycarbonate products can withstand disinfection by steam, detergents, heating and large doses of radiation without yellowing and physical property degradation, they are widely used in artificial kidney hemodialysis equipment and other medical devices that need to operate under transparent and intuitive conditions and require repeated disinfection, such as the production of high-pressure syringes, surgical masks, disposable dental appliances, blood separators, etc.

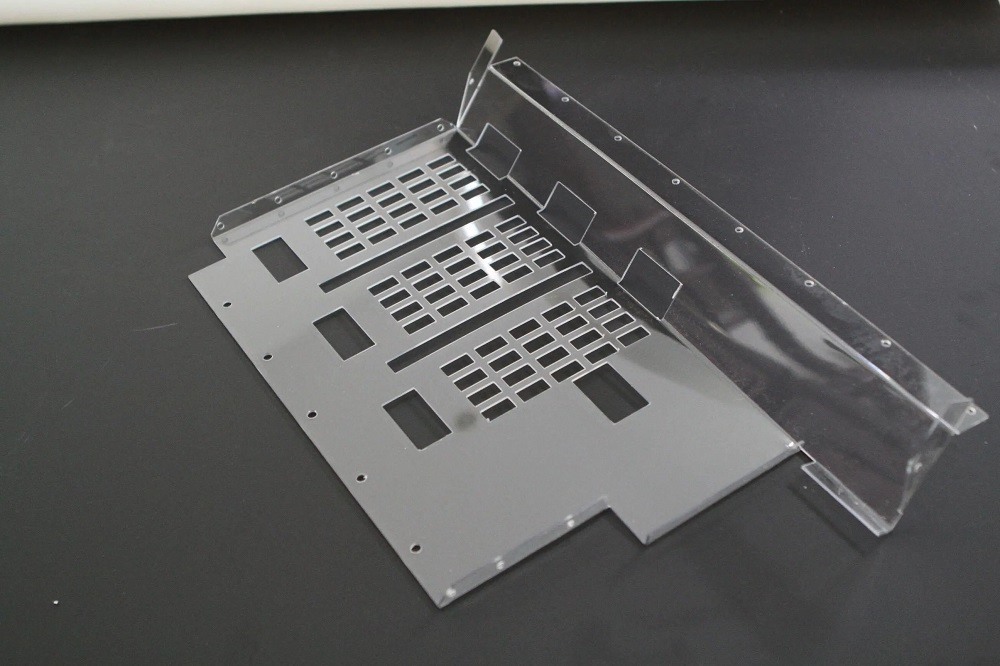

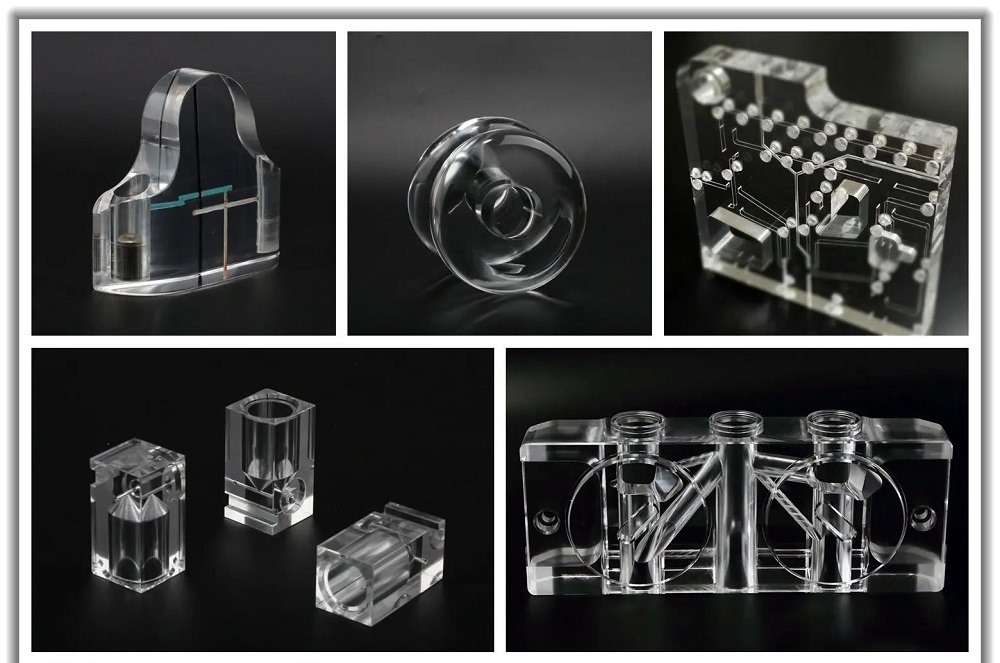

Custom Polycarbonate Parts Display

For 17 years, we have been following the highest standards of mechanical manufacturing, rigorously inspecting every stage of the production of custom polycarbonate parts to ensure they meet our quality requirements. Our work ethic has made us experts in the field of plastic parts in Shenzhen, China. This is why the Fortune 500 companies trust us and why establishing a CNC machining factory is valuable to Tuofa.

People Also Ask

Polycarbonate vs Acrylic

Both are transparent plastic, in the same thickness, the same raw material particles, Acrylic than Polycarbonate light transmission rate is 2-3% higher, are close to 90%, the naked eye is not easy to distinguish. But the other performance differences between the two is still relatively large, after all, is 2 kinds of plastic material. Polycarbonate vs PVC

1、Different performance |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home